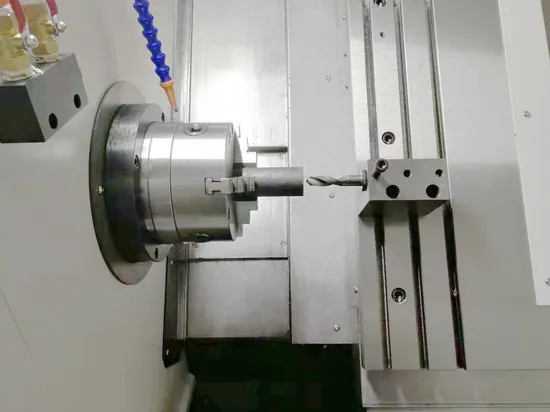

Tt5050 High Rigidity Precision Metal 2 Axis Turning Slant Bed CNC Lathe with Turret Tool

| Negotiable | 1 Piece (MOQ) |

Basic Info.

Model NO.

TT5050

Type

Specialized Lathe

Processing Accessory

Chuck CNC Lathe

Tool Holder

Single-tool Holder CNC Lathe

Power Source

Electric

Controlling Mode

CNC

Automatic Grade

Automatic

Setting Mode

Table

Precision

High Precision

Certification

CE, ISO 9001

Condition

New

Transport Package

Wood Case

Specification

2665*1740*1850mm

Trademark

MacTech

Origin

Jiangsu

Product Description

Product DescriptionProduct structure and features-frame and torque diagram

Casting treatment

Tempering treatment in casting factory

Aging treatment in factory more than 180 days

High rigidity and high speed linear guide way ensure machine more stable and precision

Headstock hole boring by special purpose machine;

Diameter error within 0.005mm. Roundness error within 0.002mm

Spindle noise not more than 80dB

Spindle temperature rise within22 ºC

The temperature difference within 5 ºC

High-end testing equipments

Roundness meter

Each machine will be inspected by laser interferometers before delivery

| Machine model | TT5050 |

| Max swing over bed | Φ520mm |

| Swing dia. over slide | Φ210mm |

| Turnning diameter | DiscΦ320mm |

| Turnning Langth | 550mm |

| X travel | 190mm |

| Z travel | 550mm |

| X/Z fast moving speed | X/Z:24/24m/min |

| Spindle max speed | 4000rpm |

| Spindle model | A2-6 |

| Spindle taper | Metric 80 |

| Spindle hole diameter | Φ71mm |

| Through bar diameter | Φ50mm |

| Tailstock travel | 120mm |

| Tailstock daimeter | Φ85mm |

| Tailstock taper | MT4 |

| Turret | 8T/80 servo turret |

| Square tool size | 25*25 |

| Boring tool diameter | Φ32 |

| Chuck size | 8 inch hollow hydraulic chuck |

| Overall dimension | 2665*1740*1850mm |

| Net weight | 3300kg |

Company Profile

>> High Pressure 3/16" Male Thread Brass Anti Drip Fog Spray Nozzle Misting Metal Nozzle

>> Versatile CNC Milling Machine for Enhanced Grinding and Polishing Solutions

>> SHENGKE Fashion Bracelet Watch For Woman Alloy Band Buckle Watch Gifts For Women Reloj Para Mujer Custom Logo Jewelry Watch OEM

>> HC-D009B Hospital Medical Supplies Digital Radiography Equipment High Frequency Mobile C-arm System

>> Modern Design Five Grey Cloth Drawers Large Capacity Sundries Storage Rack As You Require

>> High Performance Stainless Steel Front Loading Washing Machine Automatic 9Kg

>> Cw61140h/1-Swing Over Bed 1400mm-16m 15tons Workpiece Loads Heavy Duty Horizontal Lathe Large Size Lathe Torno

>> Underground Used Septic PP Plastic Material Household Biogas Septic Tank For Sewage Treatment

>> universal power tailgate kit car remote control electric tailgate for KIA KX7 rear door 2017-2018

>> Fully Automatic 3/8 Inch 2 Inch 220V 380V 1phase 3phase 10dies Hose Crimping Machine Manufacturer

>> 23180689 Rear light lamp FOR CADILLAC SRX 2010-2015

>> turkish pistachio new crop pistache phistachios pistazien pistachio nuts in shell raw shelled turkish pistachio

>> ESD Permanent Anti-Static Component Storage Red/Yellow Box

>> Heavy-Duty Automatic Hydraulic Dock Leveler for Warehousing Solutions

>> Self Propelled Track Crawler Scissor Lift Tracks Electric Crawler Scissor Lift

>> Ice lolly packing machine

>> Aquarium bio filter media plastic bio ball

>> 2024 Western Pear Big Head Pear Fresh Pear Comis Red Pear in China

>> Full-Automatic Meat Dicer for Large-Scale Production Frozen Meat Cube Dicing Machine 2D/3D Meat Cube Dicer

>> Outdoor Extra Large Post Box Parcel Drop Box,Package Delivery Boxes for Outside Anti-theft Design

>> Metal Plunger 1ml Standard Luer Lock Glass Syringe for Thick Oil Distillate

>> body kits for Mercedes benz ML class w166 AMG front rear bumper

>> Versatile Xiamen PVC Backpack - Stylish, Durable Tarpaulin Design

>> Full Automatic Double Layer temperature Keeping Coolant Box Blow Moulding Machine

>> Wholesale high quality Auto parts ENCORE TRACKER car Charge air cooler radiator For Chevrolet Buick 95026333

>> High Quality Matte Chrome Shaving Razor and Brush Stand Safety Razor Stand Holder

>> Electric Kettle with Visible Water Gauge

>> Sea Stella / Aquitalia 46FT Luxury Sport Power Boat

>> Plastic Tool Box Set-7PCS (SF-G711--SF-G717)

>> New Design Peacock Pattern Korean Velvet Printing Fabric for Performance Clothing