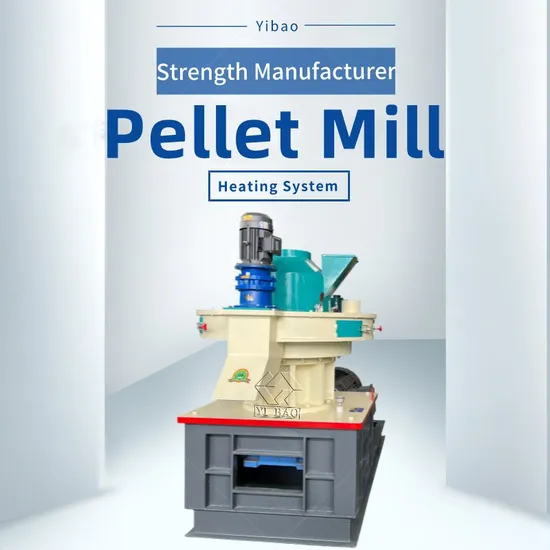

Biofuel Pellet Making Machine Biomass Pelletizing Machine

| US$4,117.00-12,500.00 | 1 Piece (MOQ) |

Basic Info.

Model NO.

YB-450

Automatic Grade

Automatic

Controlling Mode

Artificial

Energy Saving

Energy Saving

Certification

CE, ISO

Warranty

1 Year

Customized

Customized

Condition

New

Color

Multi Color

After-sales Service

Online Supoport

Product Name

Biomass Pellet Mill

Raw Material

Wood Sawdust /Rice Husk/Straw

Pellet Size

8mm

Productivity

1.5-2t/H

Raw Material Moisture(%)

18%

Usage

Making Biomass Pellets

Weight

2900kg

Length of Pellets

Adjustable Pellet Machine Suppliers

Applicable Industries

Energy & Mining, Wood Pellet Production Plant

Spindle Speed

1450r/Min

Specification

1400*750*1550

Trademark

Yibao

Origin

Henan

Production Capacity

100 Pieces/Month

Product Description

Product DescriptionPellet Mill is a kind of biomass energy pretreatment equipment. It mainly uses agricultural and forestry processing

waste such as wood chips, straw, rice husk, bark and other biomass as raw materials, and solidifies it into high-density

pellet fuel through pretreatment and processing.

Production Line

Wood chipper:Process logs into small chips within 20mm

Hammer mill:Processing of wood chips into sawdust less than 5 mm in size

Rotary dryer:Sawdust with a moisture content of no more than 18%

Wood pellet machine:Make dry sawdust into pellets

Cooler:Cools the pellets from70-90 ºC to room temperature

Packing machine:Pack the pellets into a plastic bag

Product Parameters

| Model | YB-450 | YB-550 | YB-750 | YB-900 |

| Power(KW) | 45 | 55 | 75 | 90 |

| Spindle Speed(r/min) | 1450 | 1450 | 1450 | 1450 |

| Die diameter(MM) | 400 | 450 | 500 | 550 |

| Output Size(MM) | 4-12 | 4-12 | 4-12 | 4-12 |

| Granulation Temperature(ºC) | 80-100 | 80-100 | 80-100 | 80-100 |

| Raw material moisture(%) | 15-25% | 15-25% | 15-25% | 15-25% |

| Voltage(V) | 380 | 380 | 380 | 380 |

| Capacity(t/h) | 0.6 | 0.8 | 1-1.2 | 1.2-1.5 |

| Size(mm) | 1400*750*1550 | 2600*1300*2300 | 3500*1600*3200 | 4600*2300*3800 |

| Weight(T) | 2.9 | 3.6 | 5.6 | 6.8 |

Finished Product

Factory Tour

Henan Yibao Machinery Equipment Co., Ltd. is specialized in researching developing and manufacturing

fuel particle equipment, wood crushing, large wood crusher, sawdust machine and other equipment, committed to

providing customers with a series of complete sets of equipment such as biomass crushing, hammer mill, drying,

molding, cooling packaging,etc.,providing customers with industry risk assessment, investment analysis, and

configuration and design solutions based on the on-site space of the customer's factory.

Our Team

Customer Feedback

Certifications

>> French high-grade anti-theft stainless steel garage door is suitable for villas, apartments and other places

>> 1bjx Series Middle Duty Disc Harrow/Disk Harrow/Loosener/Scarifier/Cultivator

>> 1wan+4LAN 10/100m Adaptive Dual SIM 4G Wi-Fi Router

>> 180 C Degree High Temperature Resistant Film for Two-Tone Fineline Masking

>> All in One Windows 10 Touch Screen POS Terminal/Cash Register

>> PE Film Heat Shrink Wrap Machine of L Bar Sealing Cutting Machinery

>> Xsl-16W Double Wall Sleeve Paper-Cup-Machine Ripple Sleeve Hollow Jacket Machinery High Speed Automatic Paper Cup Making Machine for Disposable Coffee Cup

>> 12*40W RGBW 4in1 LED Rattlesnake Beam Dyed Stroboscopic Strip Lighting

>> Wholesale Custom Price 6 Chamber Digital Air Compressor Massager Therapy Pneumatic Rehabilitate Pressure Therapy

>> Walking tractor harvestor, Shuhe brand,4GL-120 wheat and rice harvester

>> Taijia Schmidt Hammer Rebound Testing Concrete Testing Equipment Concrete Test Hammer

>> Agricultural Tillage Rake Machine Tractor Parts Power Wheel Landscap Rotary Tiller Gearbox

>> Trupunc CNC Punch Press Tools Holder for Trumati/Tc 500r, 600L, 1000r Machine Cartridge Dies Rtc Tool Cartridges Accessories Quick and Reliable Punching Change

>> Air Filled Salvage Lift Flotation Bags for Boat

>> SINOBI Creative Watch Men Silicone Band Watches Quartz Mens Watch Sets Wholesale Wristwatch S9802G Jam Tangan Pria

>> Metal round cigar humidor hygrometer

>> HC-A025 Wholesale medical sterile ultrasound transmission gel with competitive price 0.25L 0.5L 1L 5L

>> X5 series E70 Left Inner Xdrive30i 48i X5 E70 tail light for 2008 2010

>> Warsun MD9 Outdoor Multiple Light Sources COB Fishing Motion Sensor Waterproof Ipx5 Adjustable 1000lm Powerful Rechargeable Headlight

>> Aluminium Ceiling Rolling Mill Steel Suspend Baffles Roll Forming Machine for Ceiling Decoration

>> Mug Maker Ceramic Porcelain Candle Jar Holders

>> Full Servo Motors Ear Loop Welding Machine with Packaging Machine

>> H/a Type Automatic Bird Harvesting Broiler Chicken Battery Breeding Cages

>> British Type Fiberglass Handle Claw Hammer

>> API Certification Drilling Manual Tong Power Tong Dies and Slip Inserts

>> High Quality Plain Dyed Custom Beanie Hat Custom Logo Cap

>> Gbr-Be1941 19X15W RGBW 4in1 LED Zoom B-Eye Moving Head Light

>> 3D CNC Router Stone Sculpture Cutter Granite Engraving Machine Quartz Marble Tombstone Carving Machine

>> Egg Tray Machine for Waste Paper Pulp Moulding Plant

>> Disposable Women Travel Sterilization Day Throw Pants 100% Cotton Underwear