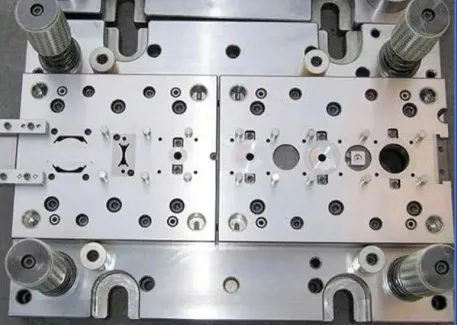

Custom Brass Aluminum Stainless Steel Sheet Metal Deep Drawing Stamping Parts Stamping Mold

| US$200.00-2,500.00 | 1 Set (MOQ) |

Basic Info.

Model NO.

SC-m-177

Material

Carbon Tool Steel

Processing Method

Punching and Shearing Mould

Technics

Forming Die

Process Combination

Progressive Die

Manufacturing Technology

Computer Technology

Driving Motor Type

Reaction Type

Mold Cavity Technology

CNC Milling

Milling Speed

High Speed

Parts Detection Method

Measurement of Three Axis NC

After-sales Service

Yes

Capacity

200sets/Year

Mould Working Life

300, 000 - 1, 000, 000 Times

Surface Treatment

Chromium Plating, Td, Polishing, Paint Spraying

Mould Raw Materials

Cr12MOV, Skh-9, SKD11, DC53, 45#, etc

Transport Package

Wooden Box

Specification

custom-made

Trademark

SC

Origin

China

HS Code

8480719090

Production Capacity

100sets/Month

Product Description

Product Description| Item | Description |

| Place of Origin | China |

| | Guangdong |

| Brand Name | OEM |

| Model Number | SC-m-156 |

| Shaping Mode | Punching Mold |

| Product Material | Metal |

| Product | Household Product |

| Mould life | 300,000 strokes, 1,000,000 strokes |

| Material | D2,45# steel |

| Mould type | progressive stamping mould, single stamping mould etc. |

| Packaging | foam,wooden case etc. or according to customer's information. |

| OEM&ODM | Accepted |

| Sample time | 7 days and free |

| Drawing format | PDF, STP,STEP,DWG, CAD |

| Mould test | Accepted |

| Process | design,CNC,heating treatment, grinding,wire cutting ,etc. |

| Port | Guangzhou |

Detailed Photos

Product Parameters

| Brand Name | OEM |

| Product Name | Metal Stamping Die/Mould |

| Tolerance | ±0.002mm |

| Material | SKD11, SKD 61, Cr12MOV, D2, SKH-9, RM56, ASP23 etc. |

| Design Software | AutoCAD, Solid works, PRO/E, UG |

| Standard | ISO9001 |

| Mould Type | Compound Stamping Die, Single Stamping Die, Progressive die or according to Customer's requirements |

| First Trial | 15-25 days after mold drawing confirmed |

| Mould Life | Depends on customer's production capacity |

| Quality confirm | Can send strip layout of die, testing video, inspection certificate and sample of product |

| Package | PE bags and carton for products, wooden case for Die/mold, or as customer's requirements |

Packaging & Shipping

Company Profile

Zhongshan SiChuang Precision Technology Co., Ltd. specilizes protype parts ,machining CNC, mold design,mold manufacturing. The material can be Metal,Steel,Cr12,Cr12mov,SKD11,aluminum etc. We are located in Xiaolan Town, Zhongshan City. We have a strong team with extensive experience and years of specialized knowledge ,manufacture the parts to specified requirment

Our Advantages

20 Years of industrial experience, professional China manufacturer of Stamping Die and Sheet Metal Processing /Stamping with one-stop sevice.

We are mainly focus on the services of Home Appliance, Automobiles, Motorcycles and other industrial customers, from mold design, processing, assembly and debugging, to the stamping automation equipment matching manufacturing full process.

We have our own R&D team to provide you with feasible manufacturing solutions. Scichuang can provide customers with various small batch products according to your delivery requirements.

After Sales Service

If any NG parts including damage during shipment,parts out of tolerance or cosmetic problem from our our factory found at customers, we will reworking at first time or you can refund from us.We are answering you any questions all the time about the products, such as what our process and try our best to work with customers to resolve their problem.

FAQ

1. Curling Curling is a stamping process that rolls the edge of the process part into a nearly closed circle. The axis of the curling circle is straight.

2. Flanging Flanging is a stamping process that rolls the upper edge of the hollow part into a nearly closed circle.

3. Drawing Drawing is a stamping process that changes the straight raw material or process part into a curved surface. The curved surface is mainly formed by the extension of the material at the bottom of the punch.

4. Stretch-bending Stretch-bending is a stamping process that realizes bending deformation under the combined action of tension and bending moment, so that the entire curved cross-section is subjected to tensile stress.

5. Bulging Bulging is a stamping process that expands hollow parts or tubular parts radially outward. Sectioning Sectioning is a stamping process that divides the forming process part into several parts.

6. Leveling Leveling is a stamping process that improves the flatness of local or overall flat parts.

7. Undulating forming It is a stamping process that relies on the extension of the material to form a local depression or convexity in the process part. The change in material thickness during undulation forming is unintentional, that is, a small change in thickness is naturally formed during the deformation process, not a design requirement.

8. Bending Bending is a stamping process that uses pressure to cause plastic deformation of the material, so that it is bent into a shape with a certain curvature and a certain angle.

9. Chiseling Chiseling is a blanking or punching process using a sharp-edged chiseling die. There is no lower die in chiseling, and the material under the material is just a flat plate. Most of the punched materials are non-metallic.

10. Deep hole punching Deep hole punching is a punching process when the hole diameter is equal to or less than the thickness of the punched material.

11. Blanking Blanking is a stamping process that separates the material along a closed contour. The separated material becomes a workpiece or process part, most of which are flat.

12. Shrinking Shrinking is a stamping process that pressurizes the open part of a hollow part or a tubular part to shrink it.

13. Shaping Shaping is a stamping process that relies on material flow to slightly change the shape and size of the process part to ensure the accuracy of the workpiece.

14. Trimming Trimming is a stamping process that cuts off a small amount of material along the outer or inner contour to improve the edge finish and verticality. The trimming process generally also improves dimensional accuracy.

15. Hole turning Hole turning is a stamping process that turns the material into a side flange around the inner hole.

16. Flanging Flanging is a stamping process that turns the material into a side short edge around the outer curve.

17. Drawing Drawing is a stamping process that turns a straight raw material or process part into a hollow part, or further changes the shape and size of a hollow part. During drawing, the hollow part is mainly formed by the material outside the bottom of the punch flowing into the die.

18. Continuous drawing Continuous drawing is a stamping method that uses the same die (continuous drawing die) to gradually form the required shape and size on a strip (coil) through multiple drawing.

19. Thinning and drawing Thinning and drawing is a drawing process that further changes the shape and size of the hollow process parts and intentionally thins the side walls.

20. Reverse drawing Reverse drawing is a drawing process that turns the inner wall of the hollow process parts outward.

21. Differential temperature drawing Differential temperature drawing is a drawing process that uses heating and cooling methods to make the temperature of the part to be deformed much higher than the temperature of the deformed part of the material, thereby increasing the degree of deformation.

22. Hydraulic drawing Hydraulic drawing is a drawing process that uses liquid in a rigid or flexible container to replace the punch or die to form a hollow part.

23. Beading Beading is a type of undulation forming. When the local undulation appears in the form of ribs, the corresponding undulation forming process is called beading.

>> High Quality Hydraulic Surface Grinding Machine with Dro Lk250ahd

>> High Pressure Car Washer with Full Automatic Function Car Wash Machine Automatic

>> 60inches 9gg Kailong Double System Flat Knitting Machine for Sweater with Dark Blue

>> Popular Fashion Design Frames Anti Blue Light Frames Eyeglasses High Quality Innovative Metal Eyewear 2021

>> OEM ODM Custom Soft Plush Toy Stuffed Animal Plushies Eagle Mu100581

>> Apollo Elevator Ard TPS Series Elevator Automatic Rescue Device TPS-10 TPS-11 380V 11kw

>> Quality After-Sales Strength Manufacturers Flying 20W 30W 50W 100W Fiber Laser Marking Machine for Metal Factory Direct Selling

>> Fb-9k CE 2CH High Power Audio Stereo Amplifiers

>> Mini Non-Marking Tires 200kg 3.6-6m Boom Lift Self-Propelled Vertical Mast Lift Work Platform

>> LED Headlight and Rear Brake Light The Latest Model of Handicapped Safe 4 Wheel Electric Scooter for Adults (FOB Price Does Not Include Freight and Tax)

>> Plastic Chairs for Football Stadium Basketball Stadium Chairs Jy-S101

>> 13CM Metal Alloy Car Gear Shift Extension Replacement Stick Shifter Knob Head for Most Manual Vehicle

>> Woodworking Machinery Panel Precision Cutting Plywood MDF Solid Wood Sliding Table Panel Saw

>> BBQ-Flavored Chicken Wing Pairs (Classic Taste) Juicy Chicken

>> High Quality Optional Heating Source Cooking Mixer Sauce Cooking Pot with Planetary Mixing

>> Riha Customized Offer Molding Products Injection Mold Plastic Clip Hot Sale Dampers

>> Plastic Recycling Machine PP PE Film Bag Recycling Washing Line

>> LUYUAN FBQ3 Plus 48V20AH Lead acid/CSP 400W 6X Liquid Cooling Motor Electric Scooter

>> PPR PVC HDPE Pipe Fittings Injection Molding Machine

>> Construction Hoist--Construction Elevator-Building Elevator-Building Hoist-Overall Lifting

>> Ilda Ttl 5W 8W RGB Full Color Animation Laser with 9*10W 4in1 LED Stage Moving Head Laser Light (MHLS-W5000/W8000)

>> Nordic Style Outdoor Round Rope Garden Baby Camping Hanging Hammock

>> Japan Used Komatsu PC130-8 Crawler Excavator PC 130 Small Digger 130-8 12ton

>> Industry Conveyor Belt Sand Conveyor Belt

>> Factory Price EPDM Rubber Granules for Artificial Grass Infilling Anti-UV EPDM Material for Playground

>> Precision CNC Machining Parts for Mobile Phone Camera Fixtures

>> Animal Fleeces Sheep Wool Goat Cashmere Fiber Carding Machine Manufacturer

>> Accurl CNC Press Brake 175 Ton CNC Plate Bending Machine

>> Custom Plastic Material Auto Spare Plastic Mould Molding Injection Parts

>> 2020 Year Concrete Boom Pump Zoomlion 56m 8X4 with Sca Nia Chassis Used Concrete Pump Truck