Power Cable 4 Core Armoured Cable 400mm in China

| US$1.00-99.00 | 100 Meters (MOQ) |

Basic Info.

Model NO.

H1Z2Z2-K/PV1-F

Current

AC Cable

Insulation Material

PVC

Sheath Material

PVC

Material Shape

Round Wire

Wire Core Material

Bare Copper Wire

Certification

ISO, CCC, CE, RoHS, VDE

Model

H1z2z2-K/PV1-F

Brand

Qinshan

Name

PVC Power Cable

Market

Global

Hot Sale Size

70mm, 120mm,400mm,95mm

Other Core

1 Core, 2 Core, 3 Core, 4 Core, 5 Core

Type

Low Voltage

Transport Package

Wooden Drum

Specification

4x50mm2

Trademark

QINSHAN

Origin

China

HS Code

8544492100

Production Capacity

8000000meters/Month

Packaging & Delivery

Package Size

10.00cm * 10.00cm * 5.00cm

Package Gross Weight

0.500kg

Product Description

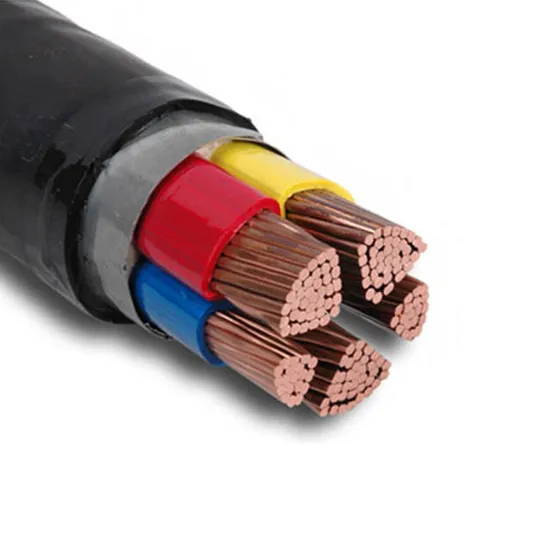

Power cable 4 core armoured cable 400mm in ChinaConstruction : Conductor: Solid & stranded copper wire class1&2 acc.to IEC60228 Solid & stranded Aluminium wire Insulation:PVC Compound Filler: PVC Compound Sheath:PVC Compound Sheath Color:White ,Black,Grey Techical Data :

Standard:IEC 60502-1 / VDE 0276 /NT88-22

Fixed installed: -15ºC up to 70ºC

At short circuit of max.5s up to 160ºC

Nominal Voltage : 600/1000V

Min inner bending radius:

Single coe:15D

Multi core:12D

Behaviour in fire:

Flame retardant cable acc.to IEC60332-1

Application:

PVC power cable for static outdoor application (with protection against direct UV-irradiation), in ground, in water, within facilities, in cable canals, in concrete, in conditions where heavier mechanical loads and specially tensile strains, are not expected. Used in electric power plants, transformer stations, industrial plants, metropolitan networks and in other electric plants, same as for connection of signalling devices in industry, traffic and similar.

Technical Parameters:

| No.of cores x Nominal section area | Nominal Construction of conductor | Nominal Insulation thickness | Nominal Sheath thickness | Nominal Overall diameter | Nominal Cable weight | Max.Resistance of conductor at 20ºC |

| No.X mm² | No.X mm | mm | mm | mm | kg/km | <=(Ω/km) |

| Three core PVC Power Cables CU/XLPE/PVC( AL/XLPE/PVC ) | ||||||

| 3x1.5 | 2x 1.38 | 0,7 | 1,8 | 11.3 | 130 | 12,10 |

| 3x2.5 | 7 x 0,67 | 0,7 | 1,8 | 11.8 | 170 | 7,41 |

| 3x4.0 | 7 x 0,85 | 0,7 | 1,8 | 13.1 | 230 | 4,61 |

| 3x6.0 | 7 x 1,04 | 0,7 | 1,8 | 13.9 | 305 | 3,08 |

| 3x10 | 7 x 1,35 | 0,7 | 1,8 | 17.5 | 450 | 1,83 |

| 3x16 | 7 x 1,70 | 0,7 | 1,8 | 18.2 | 615 | 1,150 |

| 3x25 | 7 x 2,14 | 0,9 | 1,8 | 19.1 | 870 | 0,727 |

| 3x35 | 7 x 2,52 | 0,9 | 1,8 | 21.1 | 1155 | 0,524 |

| 3x50 | 19 x 1,78 | 1,0 | 1,8 | 23.8 | 1530 | 0,387 |

| No.of cores x Nominal section area | Nominal Construction of conductor | Nominal Insulation thickness | Nominal Sheath thickness | Nominal Overall diameter | Nominal Cable weight | Max.Resistance of conductor at 20ºC |

| No.X mm² | No.X mm | mm | mm | mm | kg/km | <=(Ω/km) |

| Four core PVC Power Cables CU/XLPE/PVC( AL/XLPE/PVC ) | ||||||

| 4x1.5 | 2x 1.38 | 0,7 | 1,8 | 12.1 | 150 | 12,10 |

| 4x2.5 | 7 x 0,67 | 0,7 | 1,8 | 13.2 | 200 | 7,41 |

| 4x4.0 | 7 x 0,85 | 0,7 | 1,8 | 14.9 | 275 | 4,61 |

| 4x6.0 | 7 x 1,04 | 0,7 | 1,8 | 16.1 | 370 | 3,08 |

| 4x10 | 7 x 1,35 | 0,7 | 1,8 | 18.6 | 560 | 1,83 |

| 4x16 | 7 x 1,70 | 0,7 | 1,8 | 20.2 | 795 | 1,150 |

| 4x25 | 7 x 2,14 | 0,9 | 1,8 | 21.8 | 1130 | 0,727 |

| 4x35 | 7 x 2,52 | 0,9 | 1,8 | 24.1 | 1515 | 0,524 |

| 4x50 | 19 x 1,78 | 1,0 | 1,9 | 27.5 | 2010 | 0,387 |

| 4x70 | 19 x 2,14 | 1,1 | 2,0 | 31.7 | 2860 | 0,268 |

| 4x95 | 19 x 2,52 | 1,1 | 2,1 | 35.4 | 3870 | 0,193 |

| 4x120 | 37 x 2,03 | 1,2 | 2,3 | 39.2 | 4850 | 0,153 |

| 4x150 | 37 x 2,25 | 1,4 | 2,4 | 43.8 | 5980 | 0,124 |

| 4x185 | 37 x 2,52 | 1,6 | 2,6 | 48.7 | 7480 | 0,0991 |

| 4x240 | 61 x 2,25 | 1,7 | 2,8 | 54.4 | 9735 | 0,0754 |

| 4x300 | 61 x 2,52 | 1,8 | 3,0 | 59.9 | 12120 | 0,0601 |

Product Show:

Power cables is used in power transmission and distribution line.It does not only have excellent electric, mechanical properties,but also has powerfulresistance against chemical corrosion, heat aging and environmental stress.

Features: Conductor: creep resistance, high flexibility, strong extended, low rebound, connection stability.Insulation: high temperature resistant, anti-burning, anti-aging, strong and durable, low-carbon environment.Armored layer: Lower cost and better performance, a special form of interlocking, sturdy and tough.Outer sheath:without lead, cadmium in PVC, can be installed in wet or damp locations, can also be directly buried or laid in the construction.

>> CNC Drilling, Automatic Drilling and Chamfering Tapping Machine

>> 2020 Multi-Function Precision CNC Tungsten Carbide Saw Blade Grinding Sharpening Machine

>> Zoomlion 43m Concrete Pump Benz Truck in Good Original Condition in 2013

>> Full Automatic Fruit Vegetable Basket Machinery Plastic Making Machine Injection Molding Machine

>> HC-S275 Human teaching model half body male torso mannequin

>> Renlang clean teeth machine teeth whitening factory direct sale

>> Otcl500 Brake Lathe Machine /Dual-Funcitions Brake Disc Lathe/Brake Rotor Lathe

>> Double Solenoid Valve-Dsv520

>> Full Cover Enclosed 6020 2000wfiber Laser Cutting Machine with Exchange Table for Metal Steel

>> Brand New S Class W222 Car Front Wheel Fender Aluminium Fender 2228800118

>> Multifunctional High Pressure Vessel For Wholesales frp ro membrane shell

>> Classic IP65 Outdoor Flood Light Waterproof LED Floodlight

>> Best Food Canned Tomato Paste

>> Hand Granite Marble Slab Stone Cutting Machine for sale

>> Pdyear Factory Fast Delivery Polyester Banner Custom Printing Beach Feather Teardrop Blade Flags for Events

>> Sweet and Sour White Ginger Slices

>> T700 Metal Casting Widely Used Cost Effective CNC Vertical Drilling Machine

>> High Precision Bench Household Manual Drilling Milling Machine (KY45FG/KY40FG/KY32FG)

>> Special Vessel Aquatic Plants Harvester/Water Hyacinth Harvester for River Cleaning

>> Elegant Premium PVC Sliding Door for Modern Home Aesthetics

>> Water Shoes Mens Womens Quick-Dry Aqua Socks Beach Swim Non Slip Wetsuit UK Aqua Shoes

>> Hot-Sale Metal Rustic White Truck Planter for Home and Garden Decoration

>> Cost-Efficient 3000mm Diameter Galvanized Solid Steel Welded Steel Pipes Oxygen Tube

>> Casement window high end customized bridge broken aluminum acoustic doors and windows

>> High Torque Electric Permanent Magnet Screw Stepping Geare Synchronous High Speed Motor

>> 5m3 LPG 1000 Liter LPG Gas Storage Tank

>> Original Sandisk A2 Extreme 256GB Memory Card 128GB U3 64GB Micro Memory SD Card up to 190MB/S V30 C10 Flash TF Card with 4K HD

>> Extrusion Machinery for Large Diameter Double Hollow Wall Spiral Winding Pipe

>> 50mm*20m Thermal ECG Paper Roll Medical Recording Paper for Hospital for ECG Machine

>> Plastic Safety Orange Construction Security Fencing Temporary Warning Mesh Snow Fence/Fencing