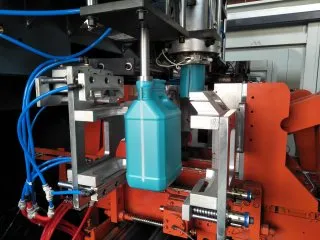

5L HDPE Two Station Two Head Extrusion Blow Molding Machine

| US$16,800.00-58,800.00 | 1 Piece (MOQ) |

Basic Info.

Model NO.

YD80II

Raw Material

HDPE

Making Method of Parison

Extrusion-Blow Molding

Automation

Automatic

Computerized

Computerized

Certification

CE, ISO9001:2008, QS

After-sales Service

24 Month

Application

Bottles, Jars, Jerry Cans, Plastic Containers

Station

Two Station

Technical Process

One Step Extrude and Blowing

Suitable Material

PE/PP/HDPE/LDPE/PETG/PVC

Max Volume

5000ml

Mold Automation

with Extrude and Blowing

Advantage

High Speed with Low Energy Consumption

Color

Customized

Transport Package

Film Packing

Specification

High Speed injection blow molding machine

Trademark

Yuanda Group

Origin

China

HS Code

84773020

Production Capacity

600 Sets Per Year

Product Description

Founded in 1970, Yuanda Group is committed to research and development and production of plastic molding equipment,Such as the Extrusion blow molding machine , PET blow molding machine ,Injection blow molding machine (IBM machine), Injection molding machine ect. including the peripheral equipment , such as refrigeration equipment and power generation system equipment. With more than 29 years old working expereice , we can offer the whole equipment for customer plastic factory produce complete project,and strong technical support and advanced complete sets of equipment for many customers in China and overseas.

Our Blow molding machine with best quality in China, due of our strong technical in this field. all important moving parts, we will study and check by computer simulation ADAMS and finite element analysis by ANSYS, advanced techincal in this field industry.so our machine with long life , win more and more good reputation from oversea.

assemblying machine , every process will be inspected by special person ,all work flow according to ISO9001 standard.our blow molding machine is best quality than others , because of our special manufactur process and best material , such as the following pictures.

Our Certification

The whole service flow is divided in pre-sale stage, manufacturing stage, installation stage and after sales service. Good communication and best advanced technical support for every customer, we always find out the best project for every customer .

Workflow Process

Our Advantages

Yuanda Group can supply the best complete line according to client product requirement

1. Advanced servo system , Moog valve from Japan , high precision and high speed , save energy and high efficient

2. Act as optional , client can choose the 3D manipulator, in order to reduce labor cost and improve production efficienty

3. Advanced hydraulic cylinder , all technical sourced from Germany , floating adjustable movement , quickly speed and quiet

4. Machine can connect with the leak tester in line , convenience , save labor cost

5. Heater cover material stainless steel with ceramic heater inside , safty , long life and energy saving 30%

6. Oil pump from USA , mainly parts from Europe, best quality

7. Flex arm clamping enhance template structure, strong Power , high precision !

8. Servo motor from Physis Italy , high speed , save energy and high efficient

9. Color control touch screen with Moog parision from Japan , more convenient operation ,with remote control module , we can remote debugging ,modify and maintain on line , it is very easy for client to solve all problems .

10. Machine can connect with the conveyor in line directly, convenience , save labor cost, save space

11. Hydraulic system and valves from Yuken Industry Japan

12. Aviation military-grade wire connector , stable ,safe and easy to install

Yuanda Group has gained huge trust from international customers based on providing high quality blow molding machines and perfect aftersales service. Yuanda machines have been delivered to America,Poland,Mexico,Colombia,Peru,Argentina,Chile,Indonesia,Malaysia,Vietnam,Saudi Arabia, South Africa,Egypt and so on.

about many other advanced technical data, please require me !

| Max. Product volume | 6 liters |

| Dry Cycle time | 5 second |

| Screw diameter | 80mm |

| Screw L/D ratio | 24 L/D |

| Screw drive power | 18.5 KW |

| Screw heating capacity | 6 KW |

| No.of heating zone | 3 zones |

| Output of HDPE | 120KG/H |

| Oil pump drive power | 7.5 KW |

| Clamping force | 65KN |

| Max.size of mold | 148-568mm |

| Mold stroke | 330 X 370mm |

| Max.die diameter | 160mm |

| Blowing pressure | 0.6 mpa |

| Air Volume | 0.6 M³/MIN |

| Cooling water pressure | 0.3mpa |

| Water consumption | 50 L/MIN |

| Size of Machine | 4.0x2.3x2.7m |

| Weight of machine | 5.5 ton |

Due to the company's fast technology update and technical confidentiality,for blow molding machine,Extrusion Blow Molding ,Injection blow molding machine ,PET blow molding machine , injection molding machine , blowing mould,plastic bottle making machine,plastic bottle mould ,bottle machine , relevant advanced technical parameters must be consulted our sales engineers. 500ml 1L 2L 3L 4L 5L Single Head With Double Stations Plastic Extrusion Blow Molding Moulding Machine Of Lowest Price

>> Zipper Stand Up Pouch Filling Nitrogen Sealing Premade Bag Freeze Dried Fruit Doypack Packing Machine

>> Best Price High Speed HDMI Cable with Ethernet 8K

>> ASTM D1598 Pipe Hydrostatic Pressure Tester

>> 1200X470 Glazed Porcelain Polished Step Stair Marble Tile

>> High Quality Imagine H-K9l UV Coating Lens Fused Silica Right Angle Prism

>> Ypoo Speed Fitness Machine Treadmill with Yifit APP Smart Electric Foldable Treadmill Running Exercise Machine Factory Under Desk Treadmill

>> Paper Tea Glass Making Machine Price

>> Hot Sale 1500W Multi-Function Fast Platform and Handheld Laser Welding Machine with Water Chiller

>> Sublimated Shorts pf White Strings with High Quality for Wholesale

>> 5.3kg 1.6L Sefic Put Into Carton, Then Packed by Wooden Box 700cc Bottle Carbon Fiber Hydraulic Cylinder

>> Cg125 Front Fork Absorber High Quality Motorcycle Parts Mtosir

>> Fiber Extracting Machine with Diesel Engine or Motor

>> Digital Rechargeable BTE Blue-tooth Hearing Aid With Rechargeable Case For People With Hearing Problems

>> Brocade Compatible 10g Zr 1550nm 80km Ddm FTTH Optical Transceiver 10g Zr SFP Transmitter Optical Module

>> 150kg-300kg/H Seed Shelling Dehulling Sheller Dehuller Machine Processing Machine Equipment

>> New Arrival Euro Fashion Strapless Slim-Fit Wide Leg Denim One-Piece Jumpsuit Club Outfits for Women Sexy

>> SMT JUKI 2010 Y Axis AC Servo Motor E9622729000 KE2010 2020 X Motor for pick and place machine

>> Industrial Use Computerized 12/15 Needles Cap/Tubular 6 Heads Embroidery Machine

>> Mushroom Shape LED IP65 Outdoor Waterproof Spot Lighting Fixture

>> Construction Machine-Scalable Platform

>> ISO&Ce Certificate Stable Lift Hopper Concrete Mixing Plant 50m3/H

>> Custom Biodegradable Matte Frosted Sealing Zipper Bags T Shirt Swimwear Zip Lock Clothing Bags With Logo

>> Factory Direct Selling 110V 60Hz Hot And Cold Uk Air Conditioner

>> Small Inner Diameter Parallel Fireworks Paper Tube Making Equipment

>> Customize energy saving mining equipment barite ore mineral hematite mineral processing spiral classifier for sale

>> 2024 New Products Deep V Sexy Bikinis One-Piece Swimwear Beachwear

>> Taijia direction and distribution of the internal steel bar test the diameter of the steel bar rebar detector

>> Exothermic Welding Joint Point Mould for Lightning and Earthing System

>> Powder Paint Grinding Mills for Powder Coating Production

>> Automatic beer aluminum can filling and sealing machine price