Zhd-Mulit-Stations 680/420 Thermoforming Machine

| US$65,000.00-75,000.00 | 1 Piece (MOQ) |

Basic Info.

Model NO.

680/420

Automatic Grade

Automatic

Sheet Materials

PP.PS.Pet.PLA.PE

Forming Servo Motor Ght(mm)

Estun

Punching Servo Motor

Estun

Magnetic Valve

Airtac

Sheet Thickness

0.2 - 2 mm

Forming Area

680 * 420 mm

Width of Sheet

400 - 700 mm

Forming Depth

100 mm

Speed

10-30 Moulds/Min

Heating Power

120 Kw

Total Installed Power

160 Kw

Feeding Motor Power

4kw

Froming Motor Power

4kw

Cutting Motor Power

4kw

Air Consumption

0.5-0.8 Bar

Transport Package

Stretchin Film Covered Wooden Pallets for Easy Loa

Specification

Overall Dimensions 4000x1700x2500mm

Trademark

WYLONG

Origin

Wenzhou

HS Code

8477590000

Production Capacity

20 Set/Sets Per Month Plastic Yoghurt Cup Making M

Product Description

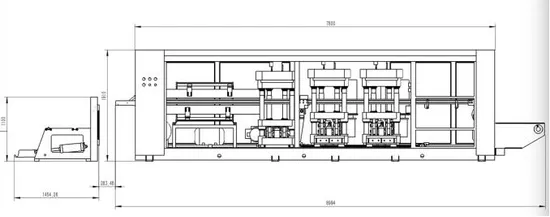

ZHD-Mulit-Stations 680/420 Thermoforming machineIntroduction

The multi-stations thermoforming machine is suitable to handle different materials, such as A-PET, R-PET, C-PET, BOPS, HIPS, PP, PLA, PVC and barrier material and to produce many items: trays, lids, fruits and vegetables boxes, flower pots, clamshells, nursery trays and plates.

It can make some products which unable to be made in one station thermoforming machine, like for example: PLA products, plastic lids or containers which has holes, the packing containers (fruit box, egg trays) with body and cover connected etc.

• High level of standardization.

• Exceptional repeatability.

• Rugged durability.

• Flexible production for a wide range of articles.

• Increased high-speed performances.

• Cutting accuracy and reliability.

• Electric drives on all the main moving parts.

• User-friendly software to control each operation and for working MACHINE STRUCTURE

| One of the Stations. (If the products has holes on it, there should be 4 stations, if not, 3 stations.) | |

| Servo Motor We have servo motors on sheet feeding part and stacking part, to achieve better precision. | |

Material Feeding Roller |

Sheet Heating Part | |

| Temperature controller Module |

| Moulds: The moulds includes: forming mould; cutting mould; punching mould (if necessary) and stacking mould. | |

| Stacking system and Conveyor |

Specification

| Model | ZHD 680/420 |

| Sheet Materials | PP.PS.PET.PLA.PE |

| Sheet Thickness | 0.2 - 2 mm |

| Forming Area | 680 * 420 mm |

| Width of Sheet | 400 - 700 mm |

| Forming Depth | 100 mm |

| Speed | 10-30 moulds/min |

| Heating Power | 120 kw |

| Total Installed Power | 160 Kw |

| Feeding Motor Power | 4kw |

| Froming Motor Power | 4kw |

| Cutting Motor Power | 4kw |

| Air Consumption | 0.5-0.8 bar |

| Dimension | 8500 * 2400 * 2200 mm |

| Weight | 8000 kg |

Products Range

CONFIGURATION LIST

| PARTS NAME | ORIGIN |

| Forming servo motor | ESTUN |

| Punching servo motor | ESTUN |

| Magnetic Valve of Forming | Japan (SMC) |

| Magnetic Valve | Airtac |

| Cylinder | Airtac |

| Feeding Servo Motor | ESTUN |

| Stacking Servo Motor | ESTUN |

| Voltage Regulating module | China Brand |

| Temperature module | China Brand |

| Heater | China Brand |

| MSC | TRIO |

| Touch screen | FLEXEM |

| Encoder | Japan (Omron) |

| Contactor | Schneider |

| Switch | Schneider |

| Breaker | Schneider |

| Cutting servo motor | ESTUN |

| No. | Name | Photo of equipment | Technical Specification |

| Air Compressor | Motor Power :22kw | ||

| Capacity : 3.8m3/ 0.8/mpa | |||

| Dimension:1.2*0.88*1.55m | |||

| Weight:600kg | |||

| Air tank : 1000L | |||

| Chiller 10P | Cooling capacity: kw/50hz 29 Kcal/Hr/50Hz 31000 | ||

| Compressor power: 8.3kw | |||

| Cooling water flow: 5.95m3 | |||

| Pipe Diameter 1-1/2'' | |||

| Chilled fluid flow: 4.95m3 | |||

| Water pump: 0.75kw | |||

| Weight:455kg | |||

| Dimension: 1450x800x1450 | |||

| Usage: Its used for cooling mould |

>> 2 Ply PVC Silver Anti Light Projection Film

>> Decorative Crystal Mirror Glass Mosaic Tile for Bathroom /Hotel/Casino/Hotel Project Wall Decorations

>> DN110*1.6 MPa PE Drain Pipe Water Supply Pipe PE Water Pipe

>> 2L N/Z Fold Hand Towel Napkin Tissue Paper Processing Machine

>> Mini PC OPS I3 I5 I7 Mini PC 4K for Whiteboard and Interactive Display Industrial Office School Computer

>> Smart Portable Folding Electric Self Balancing Scooter

>> Advanced Pneumatic Feeding Machine for Plastic Processing Solutions

>> 15 Pieces Bi-Metal Hole Saw Set with Aluminum Box

>> PCD Herring-Bone CNC Wood Pre-Milling Cutter for Edge Banding Machine

>> 2/3/5/7 Layer Corrugated Cardboard Production Line Carton Box Making Machine

>> Seto Face Plate Four-Bit Sc Fiber Optic Cable Broadband Socket Panel

>> Wholesale Plastic Stainless steel double blade free logo toothing serration hackly zigzag sawtooth wave jagged cigar cutter

>> 13% Discount Linear Atc CNC Wood Router Auto Tool Change CNC 3D Wood Carving Cutting 1325 Atc CNC Router

>> Children′s Wooden Trapeze Swing Bar with Plastic Gym Rings Swing Set

>> Original Color Toner Cartridge for Xerox 7525 7530 7535 7545 7556 7830 7835 7845 7855 7858 006r01513 006r01514 006r01515 006r01516

>> 1 Ton Hydraulic Hammer Mini Excavator Mini Digger Excavator Fwj-900

>> Metal Milling Machines Small Milling Machine 4hw 5hw China Turret Milling Machine

>> Yk-Hpd0709 CNC Drilling, Milling, Tapping, Chamfering Machine for Pipes, Tubes

>> Manufacturer sale High quality large diameter 100% Virgin white Extrusion ptfe rod

>> Flower Box Roll Forming Machine Galvanized Raised Garden Bed Roll Forming Machine

>> Poulgry Farm Equipment for Duck Farm

>> Hot Sale Light Cylinder Honing Machine for Engine Rebuilding From China

>> 45kw-8p Wire Saw Machine for Stone Quarrying

>> Advanced LNG Marine Fuel Tank - Ideal for Large Marine Vessels

>> OEM A356 gravity casting aluminum 2jz/Is1 intake manifold

>> Zoyer Eastman Km Auto-Sharpening Straight Knife Cloth Cutting Machine (ZY-T3)

>> Exporting Extremely Convenient Bamboo Skewers One Time Using for Grill BBQ Shop

>> Dental Mesh Base Standard Roth 022 Red Paper Orthodontic Metal Bracket Braces

>> oil seal 90136849 90289512

>> ZICAR furniture PVC and ABS Pre milling corner rounding Edge banding machine edgebander automatic