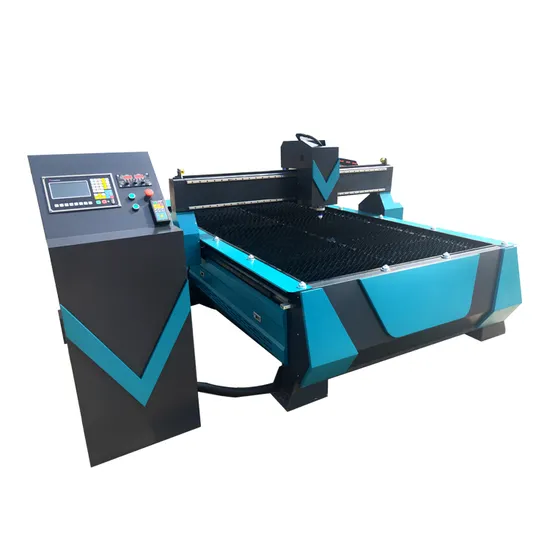

Maquina De Corte Plasma 1500X3000mm Stainless Steel CNC Plasma Cutting Machine

| US$5,600.00-8,600.00 | 1 Set (MOQ) |

Basic Info.

Model NO.

D3015

After-sales Service

24 Hours Online Service

Warranty

3 Years Warranty

Customized

Customized

Layout

Horizontal

Cutting Material

Copper, Carbon Steel, Iron, Aluminum, Metal Alloy, Stainless Steel

Automatic Grade

Automatic

Power Source

Electric

Cutting Mode

Plasma Cutting

Model

D3015

Plasma Generator

Huayuan

Plasma Power

65A 100A 120A 160A 200A

Cooling Type

Water Cooling

Water Cooler

Standard

Functions

Metal Sheet Cutting

Cutting Area

2500*1300mm / 3000*1500mm /4000*2000mm / 6000*2000

Servo Motor and Driver

Japan FUJI

Processing Precision

0.1mm

Reposition Precision

0.02mm

Vertical Travel of The Plasma Torch

300mm

Maximum Cutting Speed

12000mm/Min

Software

Starcam

Control System

Starfire

Electrical Supplier

380V 50Hz / 3 Phase

Transport Package

Wooden Box

Specification

4000*2200*1900mm

Trademark

KNOPPO

Origin

China

HS Code

8456110090

Production Capacity

500 Sets/Month

Packaging & Delivery

Package Size

450.00cm * 230.00cm * 200.00cm

Package Gross Weight

3200.000kg

Product Description

Product DescriptionD3015 CNC plasma cutting machine is mainly used for metal sheet cutting . 65A , 100A , 120A , 160A , 200A power is available.Good cutting precision with servo motor .

Application

Applicable Materials

Cutting stainless steel, carbon steel, mild steel, alloy steel, galvanized steel, silicon steel, spring steel, titanium sheet, galvanized sheet, iron sheet, inox sheet, and other metal sheet, metal plate etc.

Applicable Industries

Machinery parts, metal arts , electrics, sheet metal fabrication, electrical cabinet, kitchenware, elevator panel, hardware tools, metal enclosure, advertising sign letters, lighting lamps, metal crafts, decoration, jewelry, medical instruments, automotive parts and other metal cutting fields.

Detailed Photos

Configuration

Servo Motor , Good Precision and Quality

Servo motor can improve cutting precision and machine lifetime, other brand is still using stepper motor.

Electromagnetic Collision Avoidance Function

This function can protect cutting head, very safe for metal cutting and worker.

Red-light Position

Improve cutting precision

Stronger Machine Body

The metal body on this cutter has undergone a 600°C heat treatment, and is cooled inside the furnace for 24 hours. After this is complete, it is processed using a plano-milling machine and welded using carbon dioxide. This ensures it has a high strength and a 20 year service life.

Product Parameters

| Model | D3015 |

| Plasma power supply | 63A / 100A / 120A / 160A / 200A |

| Cutting Area | 2500*1300mm / 3000*1500mm /4000*2000mm / 6000*2000mm |

| Reposition precision | 0.02mm |

| Processing precision | 0.1mm |

| Vertical travel of the plasma torch | 300mm |

| Maximum cutting speed | 12000mm/min |

| Torch Height control mode | Automatic |

| Control system | STARfire |

| Software | Starcam |

| Electrical Supplier | 380V 50HZ / 3 Phase |

Sample

Certifications

Our pipe cnc cutting machine have CE certificates , all electric drawing and quality is suitable European standard .

After Sales Service

*3 years guarantee of the whole machine and we give lifetime maintenance free of charge.

*Free training to make sure you master the operating of machine at our factory.

* 24 hours online services through Whatsapp, Skype, Email or on the phone.

*Engineers available for overseas training and after-sale services.

* Friendly English version manual and operation video CD disk.

Company Profile

Knoppo Automation is one of the world's leading manufacturers of high-tech industrial laser solutions, dedicated to providing laser intelligent equipment solutions and enabling our customers in various branches around the world to become more efficient and competitive. With more than 15,000 laser cutting systems in the market and a rapidly increasing global base, Knoppo Automation is in a favorable position to serve the international customer base, guaranteeing highest quality and shortest response times in already more than 100 countries. Our focus is on the innovation, continuous improvement and rapid development of technologies, all of which aim to increase efficiencies and flexibility, minimize costs while generating the highest levels of environmental friendliness and sustainability to our all benefit. We aim to provide key technologies and customized integration solutions for Industry 4.0 and smart factories, helping enterprises to make perfect use of the many opportunities arising in the digital age.

The product range not only comprises of flat sheet cutting systems in various designs and dimensions, but also of laser tube cutting systems, CO2 laser cutting engraving machine , laser welding machine etc . With our focused, highly skilled and experienced R & D team and a perfectly equipped and trained systematic after-sales technical department, we truly provide customer-oriented service experience.

>> 3 in 1 Pressotherapy Vacuum Roller Lymphatic Drainage Machine with Lymphatic Drainage Magnetic Therapy

>> Round Neck Orange Best Summer Cheap Custom T-Shirt For Men Hot Sale Factory Direct Price Stylish Short Sleeve for Men

>> Liugong Excavator Series 922e/915e/925e/920e Construction Equipment Machinery

>> Negotiated Aluminium Riha Offer Standard Songjiang, Shanghai Automotive Stable Structure

>> PVC sliding window design UPVC single glazed sliding windows

>> 2 Layer Bubble Film Machine Extruder Machine

>> Custom A4 A5 1 Inch Cardboard Paper Folder Office File Binder 3 Ring Binder

>> Ride-on Electric Car Toy for Kids

>> Double Folding and Tube-Sewing Machine for Dyeing Process

>> High Technology F230 Cracked Concrete Detector Meter

>> Digital Infrared Manufacturers Temperature Gun More Accurate Medical Fever Body Non Contact Adult Baby Thermometer Infrared

>> TUV certified 3 phase AC Surge Protector

>> Concrete Ride-on Power Trowel Leveling Screed Machine

>> 5 Ton CD Single-Speed Electric Wire Rope Hoist Factory Workshop

>> Professional 3 in 1 opt dpl / RF / Laser ipl hair removal machine with Medical CE approval

>> 7HP Gasoline Power Tiller / Mini Tiller (1WG4.2Q-1) for Farm

>> Agricultural Machinery Unmanned Aerial Vehicle Uav Farm Spraying Drone

>> Luzun Self Loading Mobile Mixer Truck 3.5cubic Cement Truck Jbc5500 for Sale

>> High Quality Automatic Steel Coil Slit Shearing Machine Slitting Machine

>> Hot Dipped Galvanized Mesh 8X10cm Woven and Welded Gabion Basket for Gabion Wall

>> High Quality Factory Direct Sale Screen Printed Logo Neck Strap ID Lanyards

>> Small Metal Hook Welded Recessed Detachable D Ring Hardware Buckle

>> Fully Automatic Good Price Facial Tissue Paper Cutting Machine

>> Fe Tablet,Mn Tablet ,Additives,used for alloy wrought

>> Industrial High Productivity Plastic Lump Block Shredder Machine

>> Multi-Function PC Racing Computer Reclining Leather Silla Gamer Cheap Gaming Chair

>> Factory Hydraulic Piston Main Pump Shaft Repair Kits Swing Motor Metal Pump Spare Parts

>> Auto Parts Aluminum Natural Rubber Snap In Tubeless Tire Valve TR412 TR413 TR414

>> New Rock Stone Iron Ore Hard Stone Small Spring Cone Crusher

>> LCL/FCL DDU/DDP Shipping Ocean Freight Forwarder Air Shipment Railway Logistics Sea Freight Logistics Central Asia From China to Kazakhstan