Plastic Single Screw Extruder Single Screw Mini Extruder Machine

| US$100.00 | 1 Piece (MOQ) |

Basic Info.

Model NO.

30

Type

Pipe Extruder

Plastic Processed

PE

Product Type

Extrusion Molding Machine

Feeding Mode

One Feed

Assembly Structure

Integral Type Extruder

Screw

Single-Screw

Engagement System

Full Intermeshing

Screw Channel Structure

Deep Screw

Exhaust

Exhaust

Automation

Automatic

Computerized

Computerized

Plastic Processed for

PP, PPR, PE, PA

Weight

300kg

Screw Diamater

25mm

L/D

30:1

Material of Screw

38crmoaia

Heating Power

1.2kw*2

Cooling Power

0.06kw*2

Inverter

ABB Inverter

Max. Rotating Speed

12rpm

Dimension (L*W*H)

1.5m*1m*2.3m

Voltage

220V/380V/440V

Cooling Type

Air Blow

Control

PLC Control

Screw Type

Single Screw

The Materiial of Barrel

38crmoaia

Transport Package

Wooden Cases

Specification

25

Trademark

Hannshine

Origin

Shanghai Hannshine

HS Code

84779000

Production Capacity

50000PCS/Month

Product Description

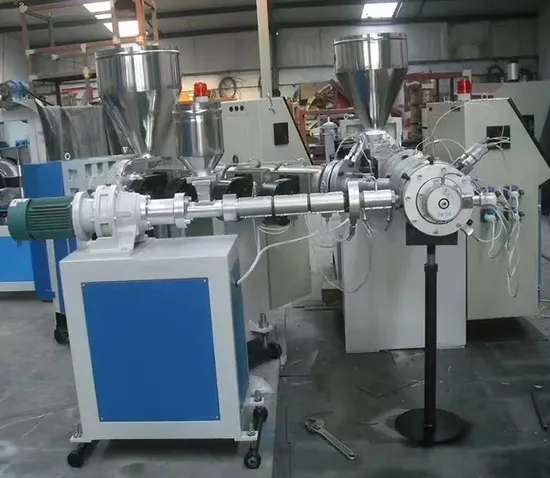

Product DescriptionSmall Single Screw Mini Plastic Extruder for Lab

Application:The plastic extruder can be used for extruding thermo-plastics such as PVC,PP,PE,PP-R,ABS.

Combined with the appropiate auxiliary machines(inducling the die head),it can

used to produce many kinds of plastic products.

Detailed Photos

Product Parameters

| Model No. 25/25 | |

| Screw Diameter | 25 mm |

| Ratio of L/D | 25 : 1 |

| Screw Material | 38CrMoAlA |

| Hardness of Screw | HV900-1000 |

| Depth of Nitrogen Treatment | 0.4-0.7 mm |

| Screw Straightness | < 0.015 mm |

| Main Motor Power | 2.2KW |

| Heating Method | Casting Aluminum Heater |

| Heating Zones | 3 Periods ( Screw Barrel 2periods , Head Piece 1 Periods ) |

| Heating Power : | 1.5KW*3=4.5KW |

| Cooling Method : | Forced Air Cooling |

| Fan Motor Power | 60W*2=0.12KW |

| Screw Maximum Rotating Speed | 40 rpm |

| Maximum Capacity | 1-3Kg/h |

| 2. Main Parts : | |

| Name | Manufacturer : |

| Main Motor | AC Motor |

| Electrical System | Siemens Contactor RKC Temperature Control Meter |

| Converter | ABB Frequency Converter |

Our Advantages

Good in plasticization

Low in energy consumption

Low noiseS

table working

Big bearing capacity

Long service life.

Main Features

Frequency conversion timing.Hard-toothed Gearbox.Material of the screw and barrel is 38CrMoAlA, nitrogen treatment, screw is designed especially for rigid PVC profile.

Screw adopts frequency conversion timing, Inverter is brand of ABB.Cast-aluminum heating coil, barrel is fan cooling.Vacuum degassing designed

Fixed quantity feeding device, frequency conversion timing, ABB inverter.Stainless hopper, side glass, with cover.Concourse chip(inside is chrome plating ) is equipped on the extruder head, pressure sensor device is also equipped with.

FAQ

How to choose proper products you want?

1.Please tell us details of what you want, like the features of raw material and what final product you want.

2.What capacity you want for the machine.

3.What is the electric device you need ? Siemens, Omron or domestic ? And your power standard?

4.When will you want the machine? (Times for delivery)

5.Other requirements about the machine you want.

How to control the quality?

1.We have technical, engineer team design the sample machinery before enter into market.

2.Production QC team ensure the machine manufacturing quality.

3.We will test the whole production line before shipment.

4.Material is Optional chosen by client to test the machinery.

>> 9W Energy Saving Lamp T8 LED Tube Lights

>> Factory Customized Solid PP Rigid Sheets PP Board Plate

>> Tensioner Eyelets Twist 6mm 7*19 High Quality Stainless Steel Wire Ropes

>> 2021 high quality reloj de cara grande factory sell hands quartz wrist analog band best watches for men

>> CNC Cylinder Head Gasket Cutting Machine Made in China

>> Automatic 3 in 1 plastic bottle water washing filling capping machine 1000-2000 water bottling plant

>> China Factory 201 301 304 304L 316 316L 309S 409 410 430 904L 2205 2507 Stainless Steel Sheet Stainless Steel Coil for Building Materials

>> Top quality unisex hoodies Top Quality Wholesale woolen hoodies

>> M271 Timing Chain Kit for Mercedes Benz W212 OE 0049972494 2710521016 TK1220-34

>> 4 Seater Utility Vehicle Electric Golf Cart Factory Direct

>> Jumping Big Square Rectangle Bungee Kid Indoor Trampoline Park

>> Mini Cable Granulator Separator Optima in 220V to Recycle Rigid or Flexible Electric Cables

>> Kc215c Air Texturing Machine Digital Thread Winding Machine Automatic Yarn Winding Machine

>> 12V/24VDC LED Warning Light with Wide Light Angle 180degree Can Pass R65, R10 Certificate for Vehicle Bump, Grill Light, Side Warning

>> Plastic Films Strength Elongation Tensile Tester Tearing Tester Instrument

>> TK1023-13 Engine Timing Chain Kit for HONDA Accord Crosstour CR-V 2.4L Engine K24

>> Factory Price Pet Plastic Wide Mouth Bottle Jars Making Blow Moulding Machine

>> ISO 9000 Certified Rare Earth Magnets NdFeB Super Strong Blocks Light Weight and Strong Magnets

>> Wholesale Double Curved Mixer Hyperboloid Mixer

>> 1/2/3/5/7 Gallon Black or White Air Pruning Pots Round Air Pruning Plant Pot with Bottom for Tree or Vegetables Faster Growing

>> Car Auto Race Shoes Boxing Wrestling Martial Art MMA Gym Weightlifting Running

>> High Best Washing Cleaning Leaves Soap Laundry Detergent Liquid

>> Mutifunctional Flat Die Pellet Maker Biomass Pellet Making Machine

>> Manufacturer Supplier Factory ODM OEM Die-Casting Aluminum 20-120W Power Saving IP66 Light Waterproof Solar Post Top Garden Light Housing LED Street Light

>> 3 Axes Machining Center CNC Milling High Speed Vmc855 Graphite Milling Machine Tools Cutting Machine Tools

>> Yigao Textile Sequin Fabric Shiny Sequins Fashion Garments Accessories Fabric

>> high quality car Headlight FOR CHEVROLET SAIL 9044747

>> OEM 68 Degree Pendent Fire Sprinkler Nozzle For Sale

>> Chinese Factory House Shoes Slippers Best Quality with Price

>> Automatic A4 Papers Paging Numbering Counting Machine