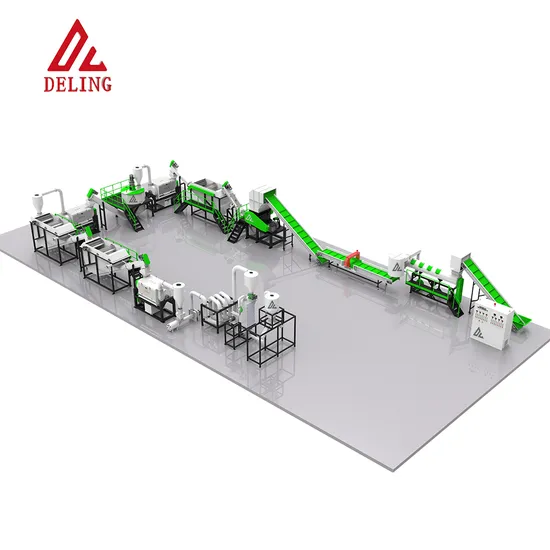

Deling Efficient 500kg Pet Bottle Washing Crushing Drying Recycling Machinery Line for Waste Plastic Equipments

| US$11,140.00-68,580.00 | 1 sets (MOQ) |

Basic Info.

Model NO.

pet recycling line

Material Processed

Plastic Bottle

Plastic Type

PET

Screw

Double-Screw

Automation

Automation

Computerized

Computerized

Condition

New

Machine Type

Pet Bottle Washing Line

Weight (T)

20

Dimension(L*W*H)

25mx5mx7m

Production Capacity (Kg/H)

500 - 3000kg/H

Automatic Grade

Automatic

Warranty of Core Components

1 Year

Power (Kw)

200

Max.Production Capacity (Kg/H)

3000kg/H

Video Outgoing-Inspection

Provided

Key Selling Points

Automatic

Voltage

380V,50Hz,3pH(According to Customer)

Application

Plastic Bottle Recycling Machine

Machinery Test Report

Provided

Transport Package

Land and Sea Transportation

Specification

304 stainless steel

Trademark

DELING

Origin

Jiangsu, China

Production Capacity

40 Sets/Month

Packaging & Delivery

Package Size

500.00cm * 500.00cm * 500.00cm

Package Gross Weight

500.000kg

Product Description

This advanced PET bottle cleaning line epitomizes efficiency and thoroughness. Beginning with de-labeling and meticulous sorting, it ensures every PET bottle is primed for processing. Bottles are then seamlessly transported via conveyor to the crusher, where they are meticulously crushed. The resultant materials are conveyed by screw to the rinsing phase, ensuring immaculate cleanliness. Post-rinsing, these materials are forwarded by screw to the friction machine for intensive friction. The friction-treated materials proceed to the steamer for a precise heating and stirring process. Following this, they are again subjected to friction. The journey continues as the materials are rinsed twice more for absolute purity, dehydrated by the dewatering machine, and then enter the distribution system for comprehensive drying. Finally, the pristine materials are transported to the storage bin, completing the entire process with unparalleled efficiency and precision.

PET Bottle Flakes Recycling Washing Line

Belt conveyer → Rolling separator → Manual pick table → Metal detector → Belt conveyer → Label Separator → Belt conveyer → Crusher → Hot washer → Friction washing → Washing tank → Dewatering machine → Hot air drying system → Label Separator → Pipeline conveyer → Storage hopper → Finished product packing

Components

Product Photograph

Q: Are you a manufacturing factory or a trader? A: We are a professional manufacturer ofcleaning line and granulation equipment, stationed in Zhangjiagang city, China.

Q: Which type should I use for my recycling plant? A:To recommend the most suitable model, please provide details on the material, including composition, size, handling capacity, and expected finished product.

Q: Can we visit your factory? A: We warmly welcome you. Once we receive your schedule, our professional sales team will ensure a comprehensive and informative visit. Q: How do I make the payment? A: We accept payments via T/T, Western Union, Cash, and L/C. For T/T, you may choose to pay 100% in advance or 30% upfront and the remaining 70% before shipment.

| Choose our worry free after-sales service | | | | | ||||

| Installation Installation manual and a guide video will be provided. What's more, We can also send engineers to your site for instructing installation, debugging machine and training workers once you required. | | | | | ||||

| Warranty During the one year guarantee period, we change those damaged original components and parts free. | | | | | ||||

| Technical Guidance all life Just call us if any problem you encountered when the whole line in operation, our technician will give you a solution within 24 hours. | | | | | ||||

Please Contact Us

>> Kingball Detail-Oriented Jiangsu Famous Trademark Nc/CNC Press Brake Turkey/Durma Press Brake

>> Air Conditioner Tube/PE Foam Pipe/Foaming Insulation Pipe Extruder Machine

>> Sim5216E Multi-Band HSDPA/WCDMA/GSM/GPRS/EDGE 3G module

>> Hot Selling Titanium Mandrel Bending 90 Degree Mandrel Bends

>> Small Dog Food Extruder Machine Dog Food Processing Machine

>> BS-460GB Middle-Sized Auto Metal Cutting Miter Band Saw Machine with PLC, Band Sawing Machine

>> Customized High Transmission Pleated/Folding Mesh Trackless Sliding Aluminum Screen Door

>> Automatic Hydraulic Disposable Cardboard Paper Plate Molding Making Machine

>> Cotton Tape Webbing

>> China Aluminum Profile Supplier V-Slot Aluminum Profile Ob 20X20 Extrusion Industrial Aluminium

>> Customized Galvanized Filter Metal End Caps For Dust Filters

>> 2021 New Fashion Men Puffer Jackets Custom Winter Warm Padded jacket Logo Embroidery Oversized Men's Puffer Jackets

>> Concrete Vibrating Table Building Material Vibration Table for Cement Mould

>> Medical Large Bio Medical Waste Pedal Bins Yellow Medical Trash Can

>> Hydraulic Press Waste Plastic Manhole Cover Making Line for Urban Projects

>> Professional Factory Custom Aluminum Extrusion Profiles 4040 4080 Industrial Aluminium Section

>> China factory automatic clay brick machine interlocking brick making machinery

>> Cheap Personalized Neck Tool Printing Polyester Sublimation Custom Lanyards with Logo Custom

>> S250 S350 High-Quality Semi Automatic Silk Screen Printing Machine China Small for Plastic

>> High Quality 10*20*2.5cm Pink Himalayan Salt Bricks for BBQ/Sauna

>> Automatic Panel Saw Precision Sliding Sawing Woodworking Machine

>> Abrasion Resistant Woven Fabric Heat Shrink Tubing Heat Shrink Tube Sleeve

>> Good Price Flow Meter Electromagnetic Flowmeter for Water, Sewage, Chemical

>> Vertical 0.75 Kw Punching Eyelet Automatic Snap Button Punching Machine

>> Circular Saw Blade - Finishing

>> Universal Sockets 24V to 220V Rated Power 4000W 6000W 8000W Pure Sine Wave Power Inverter

>> CNC H Beam Drilling Machine for Steel Structure

>> Outdoor Riding Equipment Bike Light USB Rechargeable Night Riding Lighting Waterproof Bicycle Lights Set

>> New Design Premium Wool Solid Color Knit Cold Hat Bobble Hat Woolen Beanie

>> China Factory Shimmering Mica Powder Pearl Pigments Powder for Slime, Metallic Epoxy Floor Paints