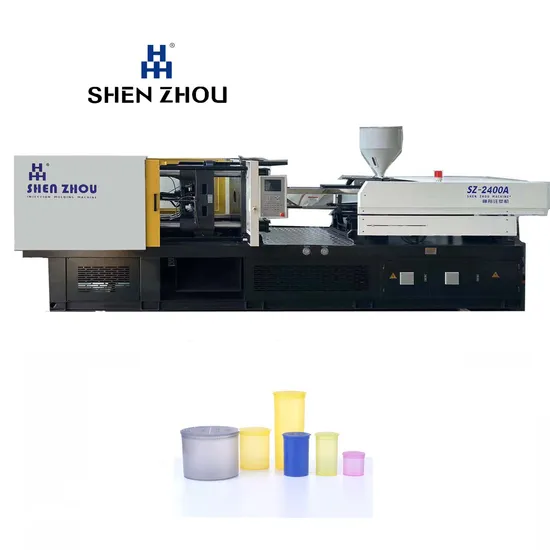

New Customized Automatic Plastic Injection Molding Moulding Pop Top Bottle Machine Sz-1700A

| US$21,000.00-50,000.00 | 1 Set (MOQ) |

Basic Info.

Model NO.

SZ-1700A

Type

Injection Blow Molding

Structure

Horizontal

Plastic Type

Thermoplastic

Plasticizing Way

Screw Type

Clamping Way

Hydraulic

Automation

Automatic

Computerized

Computerized

Certification

CE

Shaping Mode

Injection Mould

Surface Finish Process

Polishing

Mould Cavity

Multi Cavity

Process Combination Type

Compound Die

Application

Household Appliances, Commodity, Home Use

Runner

Hot Runner

Design Software

Ug

Installation

Fixed

Standard

Hasco

Customized

Customized

Plastic Material

PP/PE

Transport Package

Wooden Case

Specification

SZM

Trademark

ShenZhou

Origin

Jiangsu, China

HS Code

8480790090

Production Capacity

50 Set/Sets Per Month

Product Description

Products Variety

The plastic industry trowel is a tool used for processing and trimming plastic products. It is usually made of plastic materials and has the following characteristics and uses:

1. Corrosion resistance: The plastic industrial trowel is made of corrosion-resistant plastic materials, which can resist the erosion of chemicals such as acid and alkali, and extend its service life.

2. Lightweight and Durable: Plastic industrial trowels are lighter and more convenient to use compared to metal products, while also having high durability.

3. Non conductivity: Due to the non-conductivity of plastic industrial trowels, electric shock accidents can be avoided when handling charged objects. 4. Smooth surface: The surface of plastic industrial trowels is usually very smooth, which can effectively avoid scratches or damage to the surface of plastic products.

5. Trimming and smoothing: The plastic industrial trowel is mainly used for trimming and smoothing the uneven parts of the surface of plastic products, to achieve a smoother and smoother effect.

6. Widely used: The plastic industry trowel is suitable for the processing and trimming of various plastic products, such as plastic molds, plastic parts, plastic containers, etc. Overall, the plastic industry trowel is a tool used for processing and repairing plastic products. It has the characteristics of corrosion resistance, lightweight and durable, non-conductive, and smooth surface. It is widely used in the plastic industry, improving the quality and appearance of plastic products.

Product Description

Product Parameters

1. Customized mold Information:

| ITEM | UNIT | SZ-1700A | ||

| INJECTION UNIT | ||||

| SCREW DIAMETER | mm | 45 | 50 | 55 |

| SCREW LID RATIO | L/D | 23.3 | 21 | 19.1 |

| THEORETICAL SHOT VOLUME | CM3 | 358 | 442 | 534 |

| SHOT WEIGHT(PS) | g | 326 | 402 | 486 |

| INJECTION PRESSURE | Mpa | 219 | 178 | 147 |

| THEORETICAL INJECTION RATE(PS) | g/s | 142 | 175 | 212 |

| PLASTICISING CAPACITY | g/s | 20.1 | 26.5 | 34.2 |

| SCREW TORQUE | N.m | 1250 | ||

| MAX.SCREW ROTATE SPEED | r/min | 200 | ||

| INJECTION STROKE | mm | 225 | ||

| CLAMPING UNIT | ||||

| MAX.CLAMPING FORCE K | KN | 1700 | ||

| MAX.OPENING STROKE | mm | 460 | ||

| SPACE BETWEEN TIE BARS | mm | 480×480 | ||

| MOULD HEIGHT | mm | 180-500 | ||

| MAX.DAYLIGHT | mm | 960 | ||

| EJECTOR FORCE | KN | 45.2 | ||

| EJECTOR STROKE | mm | 115 | ||

| EJECTOR QUANTITY | 5 | |||

| OTHER | ||||

| PUMP MOTOR POWER | KW | 15 | ||

| PUMP PRESSURE | Mpa | 16 | ||

| HEATING POWER | KW | 13.6 | ||

| HEATING ZONE | 4 | |||

| SIZE | m | 5.3×1.35×1.9 | ||

| NET WEIGHT | t | 5.6 | ||

| OIL TANK CAPACITY | L | 420 | ||

| INTERNATIONAL DESIGNATION | 1700-785 | |||

| Mold information | Content |

| To be discussed | The price is for reference only,the specific price can be negotiated;if there are any other requirements,please state in advance |

| Product material | ABS,PP,PC,PA,PMMA,PS,POM and etc. |

| Moldbase | FUTABA,LKM,HASCO,DME,you can choose |

| Cavity material | 45#,50#,P20,H13,718 2738,NAK80,S136,SKD61 etc |

| Runner | cold/hot runner |

| Cavity | multi or single cavity |

| Customized | Per customer request |

| Lead time | about 25 days,depond on reality project |

| Package | standard exported wooden box packed |

| Design software | UG,PROE,CAD,Solidworks |

2. Detail information of bottle cap mold mould steel:

| Mould material | Mould hardness | Mould life |

| P20 | HRC 29-33 | 300000 shot |

| H13 | HRC>43 | 1000000 shot |

| 718 | HRC 30-36 | 500000 shot |

| S136 | HRC 48-52 | 50000 shot |

| 2344 | HRC>48 | 800000 shot |

Why Choose Us

Detailed Photos

Certifications

Company Profile

FAQ

1. Why choose us?

We not only supply the mold, but also the machine and related parts. Port city, convenient transportation.

2. How to ensure the quality of mould?

Debug on the machine before delivery to ensure no quality problems before delivery.

3. What about our after-sales service?

There is a perfect after-sales service system, super long warranty period, any product problems can contact us at any time.

4. About the price?

Higher discount for bulk purchase, price can be negotiated.

5. How long will delivery take after placing an order?

High production efficiency,short delivery time, specific circumstances can be negotiated.

>> Automatic tomato seed remove machine

>> Hep02A Gas Diesel Inline Low Pressure Electric Fuel Pump Silvery

>> Professional Service Fish Aqua Feed Production Machine + Fish Feed Pallet Making Machine Animal Feed Pellet + Floating Fish Feed Extruder Taiwan

>> 2.5 Inch Internal SSD 120GB Hard Disk 240GB Hard Disk Drive 480GB SSD

>> Iron Oxide Green 5605 Paint Coating Paper Asphalt Cement Brick Tile

>> Factory Selling Good Price High-Speed Mixer for Mixing of PVC Raw Materials

>> Aminoplus 100% Water Soluble Fertilizer Animal Source Amino Acid

>> 60t Fully Continuous Waste Tyre Pyrolysis for Diesel Oil

>> 7 Years Warranty CE ETL Approved LED Canopy Light 40W 60W 80W 100W High Lumen Output IP65waterproof Gas Station Light

>> Lab Supplies Disposable Universal Transparent 20UL Pipette Tips with Filter

>> Roll Forming Machine for U101.6 Profile

>> Sauer Danfoss Pressure Control Pilot MCV116G4204 MCV110A1017 MCV116A3501 MCV116A3204 MCV116A3102 MCV116G4201

>> High Quality High Alloy Steel Rolls for Efficient Steel Production HSS Roll

>> Eco-Friendly HDPE Plastic Custom-Made Size Pressure Casting Pallet Sleeve Box

>> Livestock Farm Animal Copper Mouth Water Pig Nipple Drinker Automatic

>> C11000 C10200 C17200 Copper Plate Supplier Price

>> Long Marc Tyre 315/80r22.5 Longmarc Truck Tires Longmarc Truck Tyres Price 11r22.5

>> Weldon Corten Steel planters as movable screens and dividers for open floor plans

>> MAICTOP auto body part handle for prado fj150 car door handle chrome 2018

>> Popular Drop Stitch Material Inflatable Catamaran Boat

>> Fruit Juicer Smoothie Milkshakes Vegetable Portable Rechargeable USB Blender

>> 7 Ton to 9 Ton Hydraulic Diesel Engine Long Boom Quick Hitch Mini New Hydraulic Medium Crawler Wheeled Excavator Machine

>> Mini Displayport to HDTV Adapter Cable Mini Display Port Dp Converter Thunderbolt High Quality for Apple MacBook PRO Air

>> Stable Performance Jaw Crusher with Discount Price

>> Chemical Bond Fusible Nonwoven Interlining Fabrics 1025hf for Embroidery

>> IP20 576LEDs/M COB Strip COB Pixel Dream Color Strip Home Decor Living Room Magic RGB COB LED Strip

>> Xk7130 New CNC Milling Machine CNC Bed Type Milling Machine for Metal Processing

>> Super Soft Solid Coral Fleece Blanket

>> Nylon Round Bar Polyamide Rods extruded Nylon Rod Flexible Plastic Nylon Rod

>> Used Original Japan Cat306 Small Mini Digger Hydraulic Crawler Excavator in Stock