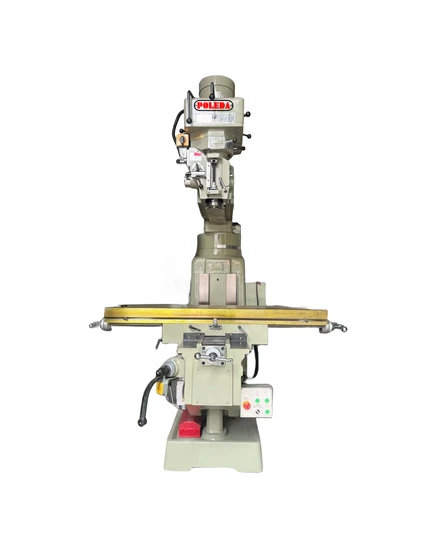

Poleda 5m/5s Universal Vertical Rocker Turret Milling Machine with High-Performance Motor, China

Basic Info.

Model NO.

5M/5S

Type

Tool Milling Machine

Object

Hardware

Structure

Rocker

Milling Cutter Type

Angle Milling Cutter

Milling Cutter Structure

Indexable Type

Controlling Mode

Artificial

Automatic Grade

Automatic

Precision

High Precision

Certification

CE, ISO 9001

Condition

New

Transport Package

Wooden Frame or Wooden Box

Specification

2000*1800*2500mm

Trademark

POLEDA

Origin

China

HS Code

84592900

Production Capacity

100PCS/Month

Product Description

Introducing the POLEDA 5m/5s Universal Vertical Rocker Turret Milling Machine, a pinnacle of engineering and precision. Proudly fashioned in China, this vertical metal turret milling machine stands unmatched in professionalism, continually striving for excellence. At Dongguan Poleda Precision Machinery Co., Ltd., we believe in constant enhancement-there is no best, only better. Discover the power and precision of the POLEDA 5m/5s Universal Vertical Rocker Turret Milling Machine. Engineered for unparalleled performance, this vertical metal turret milling machine sets new standards in the industry.Our POLEDA 5m/5s Universal Vertical Rocker Turret Milling Machine, made in China, epitomizes our commitment to professional excellence and innovation in universal milling technology.

At Dongguan Poleda Precision Machinery Co., Ltd., we uphold the philosophy that there is no best, only better. Constant improvement drives us to deliver top-tier machinery, like the POLEDA 5m/5s Universal Vertical Rocker Turret Milling Machine.

Product Description

Product Parameters

Product Introduction

The Turret Milling Machine, also known as the Rocker Arm Milling Machine, Rocker Arm Milling, or Universal Milling, is ingeniously designed with a compact structure and small footprint. Highly flexible, the machine's milling head swivels 90 degrees, rotates 45 degrees forward and backward, and the rocker arm extends while offering a full 360-degree horizontal rotation. These features significantly enhance the machine's effective working range.

Construction

Crafted from high-grade cast iron, the body of the Universal Radial Milling Machine boasts exceptional precision and longevity, thanks to artificial aging treatment. The lifting platform features rectangular guide rails with multiple contact surfaces and robust feet. High-frequency treatment and fine grinding have plastinated the slide, ensuring excellent motion accuracy and durability. The spindle, made from chrome-molybdenum alloy, is equipped with precision angular contact bearings and undergoes tempering and fine grinding to deliver strong cutting force and high accuracy.

Application

The Turret Milling Machine serves as a versatile and lightweight metal-cutting apparatus, capable of vertical and horizontal milling. It efficiently handles the milling of flat surfaces, inclined planes, grooves, and splines on medium and small parts, finding widespread use across machining, molding, instrumentation, and other industries.

Mechanical Characteristics of the Turret Milling Machine:

Constructed from m Mihanna cast iron, the machine ensures superior rigidity, deformation resistance, and stability.

The spindle, built from chrome-molybdenum alloy, undergoes tempering, heat treatment, and grinding, paired with precision bearings for formidable cutting force and impeccable precision.

The Milling Head Gear Box, also crafted from cast iron, offers excellent rigidity, minimal deformation, and greater weight for more precise cutting. This ensures the milling head's durability.

The three-axis screw's screw cap is made from advanced phosphorus bronze, providing exceptional wear resistance and a prolonged service life.

The XY axis slide, post high-wave heat treatment, exhibits excellent wear resistance, enhancing longevity. The XY axis interface features an imported wear-resistant plate, ensuring ease of operation and minimal wear rate.

Equipped with a lubrication system, the machine guarantees uniform oil distribution across points, ensuring smooth slide movement.

The machine is 100 kg heavier than similar products, providing added stability.

Powered by a robust 5hp motor, with a high-rigidity and precision NT40 spindle, this machine is ideal for handling large parts and heavy-duty cutting operations.

| Product Name | Milling machine | |

| Product model | 5M/5S/5HG | |

| Product technical parameters | ||

| dimension | Table size | 1370*305MM |

journey | Left and right stroke(X) | 800MM |

| Front and rear stroke(Y) | 380MM | |

| Up and down stroke(Z) | 380MM | |

| Arm reach | 600MM | |

| Distance from spindle end face to table surface | 100-480MM | |

| Table bearing | 350KG | |

Principal axis coefficient | Spindle taper | NT40 |

| Spindle speed | 80-5440RPM(16-speed) | |

| Spindle travel | 127MM | |

| Spindle horse power | 5HP | |

| Milling head | Milling head tilt Angle | 45° front and back |

| Lead screw | X/Y/Z-axis screw diameter | Tr32/Tr32/Tr35MM |

| Three-axis lead screw pitch | 5MM | |

| Machine size (L * W * H)(MM) | 1750*1700*2200MM | |

| Approximate machine weight | 1580kgs | |

| disposition | Accessories name | quantity |

Standard parts for machine tools | 1,Hand oil pump | 1 |

| 2,Work light | 1 | |

| 3,Organ board + protective glue | 1 | |

| 4,Lever | 1 | |

| 5,Tools and toolboxes | 1 | |

| 6,Operating instruction | 1 | |

Detailed Photos

Our Advantages

Certifications

FAQ

Frequently Asked Questions (FAQ)

Question 1.What is the MOQ for your production?

Answer: The Minimum Order Quantity (MOQ) depends on your requirements for color, logo, etc. For some standard items we have in stock, the MOQ is just 1 set.

Question 2.How do you ensure the quality of the products?

Answer: We have consistently prioritized maintaining a high level of quality. Our guiding principle is to providecustomers with superior quality, competitive prices, and exceptional service.

Question 3.What are the main products of your company?

Answer: We specialize in various types of machinery, including CNC Machines, Lathe Machines, Milling Machines, Grinding Machines, Vertical Machining Centers,Drilling Machines, Radial Drilling Machines, Sawing Machines, and more.

Question 4. What are your trade terms?

Answer:We accept Ex-works, FOB, CFR, and CIF terms.

Question 5.What are the Payment Terms?

Answer: T/T is accepted, with a 30% initial payment upon order and a 70% balance payment before shipment.

Question 6.What CNC systems do you use?

Answer: We use FANUC, SIEMENS, MITSUBISHI, SYNTEC, and HCN systems, depending on your preference.

Question 7.How can I choose the most suitable machines?

Answer: Send us your product drawings and application details, and we will recommend the most suitable machines for you.

Question 8.What kind of packaging do you offer?

Answer: Typically, we use plywood cases to ensure all goods are in excellent condition. Customized packaging is also available upon request.

Question 9.Can your plant do OEM?

Answer:Yes, we can provide both OEM and ODM services for any customer. Question 10.How about the warranty?

Answer: The warranty period is one year after delivery. Even after this period, we offer lifetime service for our machines.

>> PP PE PC PVC Second Hand Plastic Twin Screw Extruder Machine Price

>> Luxury Orange Glaze Ceramics Bathroom Decor Accessory Completes with Soap Dispenser Tumbler Soap dish Toilet brush Tray and Cot

>> master bedroom double door white wood closet slidin door for wardrobe

>> High Speed C6 C10 U1 U3 OEM 64GB Memory Card SD Card Camera Adapter Card TF Card

>> Metal Universal Swivel Head Horizontal Vertical Milling Machine XL6236 X6236

>> Commercial Feed Factory Pig Feed Pellet Making Machine Animal Feed Pellet Processing Machine

>> Custom Printed Disposable Bamboo Chopsticks For Sushi Yiyang Paper Covered Chopsticks

>> Riding on The Type of Rice and Wheat Combine Harvester Mountain Hilly Interplanting Land 1.2 Meters Cutting Machine China Manufacturers

>> Tote Foldable Bolso De Playa Waterproof EVA Mesh Beach Bag

>> ODM Multihead Weigher Packaging Machines Automatic Sweet Gummy Bears Candy Zipper Pouch Doypack Packing Machine

>> Gold Wash Machinery Mineral Gold Sand Submerged Spiral Separator Classifier Machine

>> Infra Red ABS Plastic Part Hot Plate Welding Machine Welder

>> Yamamoto Motorcycle Spare Parts Rear Spring-Air Shock Absorber for YAMAHA Jog50

>> Emergency Bleeding Control Medical First Aid Rapid Hemostasis Israeli Bandage

>> Disposable Catheter Fixation Device Picc/CVC Tube Fixation

>> /31230-71050/High Speed Clutch Bearings for Higer Buses

>> Professional Drilling Milling Machine Zx7550 Zx7550W Zx7550cw Zx7550c

>> in 2023, The New More Durable Lithium Battery Pipeline Construction Waste Laboratory Shredder Is a Hot Commodity in The United States

>> 3D Video Glasses Virtual Reality Video Glasses

>> Rsc-10050 100 Ton Single Acting Hydraulic Cylinders OEM and ODM Supported Low Lifting Jack

>> Heavy Duty Efficient Kraft Filling Pad Automatic Packaging Void Cushion Paper Machine

>> 20W Modular SKD Type Beam Adjustable LED Downlight

>> Hoe Selling Twisting Machine Parts 127mm 05-06, Ba1-Ba3" Friction Roller

>> Rotoform Steel Cooling Belt Phenolic Resin Granulars China Factory

>> Wholesale Custom Printing Bag Matte Square Flat Bottom pouch with handle Packaging pouch for salad and vegetable

>> High Speed 5 Liter 2 Cavity Pet Water Bottle Blow Moulding Machine

>> Adhesive Mount 48*18mm Internal Built-in RoHS FPC Antenna Flexible 13.56MHz RFID NFC Antenna

>> 1500X7500mm ASME Approved Medical Resin Matrix Curing Autoclave (SN-CGF1575)

>> Reliable Stainless Steel Bread Bakery Machinery with High Capacity Options

>> Heavy-Duty 1500W/2000W/3000W/6000W Fiber Laser Cutting Machinery for Metal Tube Applications