PP PE Waste Plastic Washing Recycling Machine

| US$85,000.00 | 1 Piece (MOQ) |

Basic Info.

Model NO.

FGR

Material Processed

Plastic Films,Bags, Basket

Plastic Type

PP, PE, LDPE, LLDPE

Screw

Single-Screw

Automation

Automation

Computerized

Computerized

Certification

ISO9001:2008, CE

Final Product

PP, PE Granules

Usage

Recycle PP PE Films, Bags, Basket, Jerry Cans

Final Output

Clean PP PE Scraps, or Granules

Capacity

300kg/H, 500kg/H, 1000kg/H

Motor

Siemens Standard Motor

Electrics

World Brand Electrics

Transport Package

Wood Packing with Protecting Film

Specification

25m x 2m x 4.2m

Trademark

FAYGO

Origin

Chinese

Production Capacity

100 Sets Per Month

Product Description

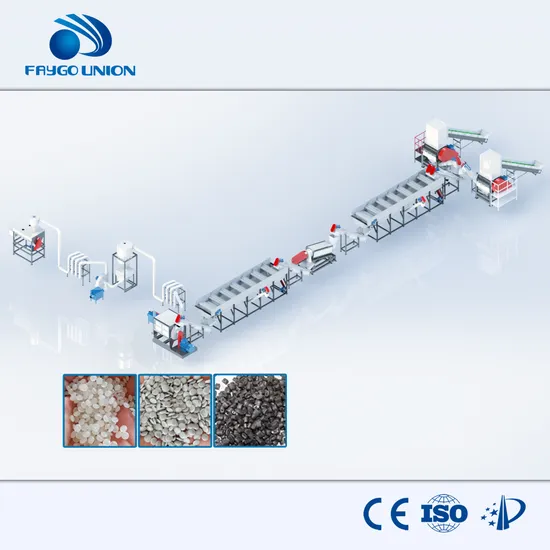

Product DescriptionPP PE Waste Plastic Washing Recycling Machine

It is widely used in recycling PP PE films and bags, such as LLDPE agriculture film, LDPE/LLDPE films, PE,PP bags, PP woven bags, jumbo bags and so on. It include plastic film crushing and washing machine, squeezing pelletizer and plastic pelletizing machine. It will make granules directly from waste plastic plastic material. With proper design, this line can also recycle plastic basket, plastic bucket, plastic pallet, jerry cans and so on.

The complete process of this waste plastic film recycling machine is belt conveyer - wet crusher - screw loader - friction washer - float washer - squeezing pelletizer - pelletizing line. The output of this plastic film recycling machine could be 300~800kg/h. For dirty material, the clients will need more washing machine for cleaning the material. According to clients workshop, this plastic film recycling machine could be arranged as "L" or "U" shape to save space.

If the clients also want to recycle righd PP PE material, such as PP PE pipes, basket, pallet, jerrycans, we can also make some special design for this plastic recycling machine, so that the clients can recycle more waste plastics.

Product Parameters

| itme/model | FGR300 | FGR500 | FGR800 | remark |

| belt conveyer | 1.1kw | 1.1kw | 1.5kw | washing and squeeizing part |

| crusher | PC800, 37kw | PC1000, 45kw | PC1200, 55kw | |

| screw loader | 3kw | 3kw | 4kw | |

| friction washer | 7.5kw | 7.5kw | 11kw | |

| float washer | 2.2kw | 3kw | 4kw | |

| squeezing pelletizer | 55kw | 75kw | 110kw | |

| air cooling system | 4kw | 5.5kw | 7.5kw | |

| conveyer | 1.1kw | 1.1kw | 1.5kw | pelletizing line |

| Single screw extruder | 90KW | 132KW | 160KW | |

| screen changer and die | 1.5KW | 2.2KW | 3KW | |

| pelletizing system | 1.1KW | 1.5KW | 2.2KW |

With so many years of experence for plastic recycling machine, we developed high efficient squeezing pelletizing system for the plastic bag recycling machine. This system can replace the centrifuge dewatering machine, pipeline drying system, agglomerator. People can save a lot of electricity and space with this squeezing pelletizer. It can get more dry material from washed PP, PE film/bag scraps. Besides, it can also easy to achieve high output like 500~800kg/h. With this squeezing pelletizing system, the clients will get the rigid PP PE scraps from the film washing machine and it is much more easy for PP PE pelletizing line.

After squeezing pelletzer, the rigid PP, PE flakes will be very hot. To cool it, the air conveying pipe will be double layer, which will put cooling water inside. We will suggest cooling conveyer after this squeezing pelletizing machine. The rigid flakes can put into simple pelletizing line to make good granules.

For more details about our waste plastic recycling machine, welcome to send you requests to our company, and we will give you reply in time.

Company Profile

Jiangsu Faygo Union Machinery is a professional manufacturer of plastic machines. It occupied an area of 18000 square meters. With years of development, its products covers plastic extrusion lines, plastic blowing machine, plastic recycling machine, air compressor etc.

Stick to the company idea is making good machine, being good person, Faygo Plast alwasy provide customers with high quality machines. Warmly welcome to visit our factory (next to Shanghai)!

FAYGO UNION GROUP has 3 branch factories.

1.FAYGOBLOW which design and make blow molding machine for PET, PE etc. FAYGOBLOW has 5 patents of invention, and 8 patents utility models. FAYGO PET blow molding machine is one of fastest and most energy-efficient design in the world.

2.FAYGOPLAST, which make plastic extrusion machinery, including plastic pipe extruding line, plastic profile extruding line. Especially FAYGOPLAST can supply high speed up to 40 m/min PE,PPR pipe line.

3.FAYGO RECYCLING, which research new technology in plastic bottle ,film recycling processing and pelletizing.

Now FAYGO UNION GROUP has more than 500 customers from different countries.

Our factory is located in Zhangjiagang city, covers an area of 26,650 square meters. It only takes around two hours driving from SHANGHAI international airport. Welcome to visit our factory, and hope to cooperate with you in the near future.

FAQ

Q: Your company is a transactional company or an industrial manufacture factory?

A: We are an industrial manufacture factory which locates in Zhangjiagang city.

Q: All of your products are made by your self or compacted via purchasing the others?

A: We have independent technical team who focus on making machines, all the products are made by our technical team.

Q: What is the ability of your factory?

A: About 100 lines per month.

Q: Do you have any other services about your products?

A: We have a lot of experience on making projects and specifications for our clients, also we have a fixed service system.

Q: How do you make the quotation for clients?

A: The price depends on quality and performance but the clients should be satisfied first.

>> Hot-Selling Efficient Hms-X01 Ultrasonic Wire Harness Welding Machine for Copper Cables New Condition

>> China Precision Hardware Parts Plastic Linear Dampers Fastener Wholesale

>> Wide Range of Fashion Style Chairman Lining Wholesale Genuine Leather Wallet for Men at Reliable Market Price

>> Versatile 8X32 Heavy-Duty Tractor Wheel for All Terrain

>> Cone Crusher Crushing Methed Drawing Hpt Series Cone Crusher Price

>> Ck6132 High Precision Industrial Metal CNC Lathe Machine

>> Best Quality STMP 98.5% Phosphate Food Grade Sodium Trimetaphosphate (NaPO3)3

>> 5SHY4045L0004 ABB IGCT

>> 8oz Flexo Printed Paper Coffee Cup Disposable Single Wall Cups Beverage Paper Cup Forming Machine

>> Customized 3/4/5 Axis Vertical Machining Center for Metal Cutting

>> Cotton canvas tote carry shopping duck bag shoulder bag reticule

>> Breeze Wind Solar Integration Power Generation/Solar Power Generation/Autofolding

>> Women and Ladies Sandals Heels Ladies Wedges Sandals

>> Auto Front Bumper Lower Grille Car Grille For Camry 2018 Hybrid LE

>> Automatic 1kg Lait En Poudre Flour Chocolate Milk Packaging Gusset Bag Vffs Chili Spice Powder Pouch Packing Machine

>> Fashion Blue Sapphire Big Stone Ring

>> Digital T Shirt Printing Machine Prices Screen Printers

>> Variable Valve Timing for Chevrolet Volt 1.4L OEM 55562222 VT1053

>> Precision Clawer Excavator for Dutch Builders

>> Screw charcoal briquetting machine philippines 100-200 kg/hour

>> High Precision EL200L Fanuc System CNC Turning Center Slant Bed Lathe

>> Cheap Price 4m 6m 8m 10m Electric Scissor Lift Lift Table with High Quality

>> Waste Plastic PE PP Film Washing Recycling Line HDPE LDPE Bottle Washing Plant PP Woven Bags Recycling Machinery

>> Taber Reciprocating Abrasion Abraser Tester and Reciprocating Wear Tester DIN52347

>> Vmc 850 High Rigidity Heavy-Duty Vertical Machining Center

>> High Performance WiFi6 1800m Wireless Dual Band Network with 4 Antennas WiFi 5g Router

>> HC-S542 Dermatology teaching skin lesion pad skin disease surgery teaching model

>> Rear Trunk car springs Gas Lift Support for Hyundai Verna

>> PF0607-PF1320 Mining Impact Crusher Price of Stone Crusher Machine

>> New Design Hot Sell Women Seamless Yoga Fitness Sportswear Seamless Leggings Bra Short Legging Yoga Set