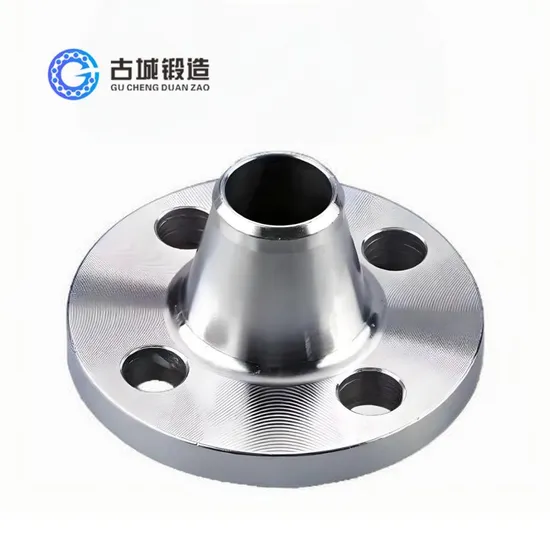

Customized Forged Ss Wn Flanges Stainless Steel Welding Neck Flange

| US$1.00-5.00 | 100 Pieces (MOQ) |

Basic Info.

Model NO.

1/2"-24"

Material

Stainless Steel

Structure

Flanges

Connection

Flanged

Sealing Surface

RF

Manufacturing Way

Forging

Certificate

ISO9001

Pressure

150# 300# 400# 600# 900# 1500# 2500#

Usage

Suitable for Water, Oil and Gas Industrial

Connection Endstsocket Weld or Threaded

NPT, Bsp, BSPT etc

Factory

Over 30 Years Experience

Transport Package

Customized

Specification

1/2"-24"

Trademark

GUCHENG

Origin

Dingxiang

HS Code

73079100

Production Capacity

50000 Pieces/Year

Packaging & Delivery

Package Size

15.00cm * 15.00cm * 15.00cm

Package Gross Weight

10.000kg

Product Description

ASME/ANSI B16.5 FORGING FLANGE -- Class 2500 Welding Neck Flanges

The presented range of Weld Neck Flanges ASME B16.5 Class 2500 is obtainable in a range of dimensions and sizes to meet particular fastening work of industrial applications. To cement our position, we are successfully presenting a wide and quality-assured gamut of Weld Neck Flanges With Threaded Hole, which are manufactured by our reliable vendors using premium-grade steel.

According to ASME B16.5, the hub of the welding neck flange can be roughly divided into a tapered portion and a straight length. The straight length of 6 mm is machined to precisely match with the adjoining pipe so that the welding can be done conveniently. Weld neck flanges are bored to match the inside diameter of the adjoining pipe. The thinner the wall of the pipe, the larger the bore through the flange. The thicker the wall of the pipe, the smaller the bore. Because of these matching relationship, there is no restriction to the flow. Turbulence and erosion are therefore eliminated.The ASME B16.5 welding neck flange shall be furnished with cut square end when wall thickness is less than 5 mm, plain bevel end when wall thickness is from 5 mm to 22 mm inclusive, or compound bevel end when wall thickness is greater than 22 mm. The butt welding ends shall be machined in accordance with the requirements of ASME B16.25. The dimensions and tolerances of plain bevel and compound bevel are illustrated in below two drawings. In particular, the wall thickness t shall conforming to the adjoining pipe's wall thickness requirement; a root face in width f of 2 mm shall be machined at the top of the bevel with tolerance of ±1 mm.Three most common facing types are available including flat face (FF), raised face (RF), and ring joint face (RTJ). Welding neck flanges are normally used in severe service applications involving high pressures, high temperatures, large external loads or cryogenic conditions.

Product Parameters

| Slip-On Flange (SO) | Weld Neck Flange (WN) |

| Threaded Flange (TH) | Lap Joint Flange (LJ) | Blind Flange (BL) |

| Nominal Pipe Size | Outside Diam. | Diam. at Base of Hub | 0.D.of Raised Face | Thickness | BORE | LENGTH THRU HUB | Diam.of Hub at Bevel | Radius of Fillet | Thread Length | |||||

| Welding Neck Socket Welding | Slip-on Socket Welding | Lap Joint | Counter Bore Min. | Welding Neck | Slip-on Threaded Socket Welding | Lap Joint | ||||||||

| D | X | G | t | B1 | B2 | B3 | B | T1 | T2 | T3 | A | R | Q | |

| 1/2 | 133 | 42.9 | 35.1 | 30.2 | To be specifed by purchaser. | 22.4 | 22.9 | 23.6 | 73.2 | 39.6 | 39.6 | 21.3 | 3.0 | 28.4 |

| 3/4 | 140 | 50.8 | 42.9 | 31.8 | 27.7 | 28.2 | 29.0 | 79.2 | 42.9 | 42.9 | 26.7 | 3.0 | 31.8 | |

| 1 | 159 | 57.2 | 50.8 | 35.1 | 34.5 | 35.1 | 35.8 | 88.9 | 47.8 | 47.8 | 33.5 | 3.0 | 35.1 | |

| 1 1/4 | 184 | 73.2 | 63.5 | 38.1 | 43.2 | 43.7 | 44.5 | 95.3 | 52.3 | 52.3 | 42.2 | 4.8 | 38.1 | |

| 1 1/2 | 203 | 79.2 | 73.2 | 44.5 | 49.5 | 50.0 | 50.5 | 111.3 | 60.5 | 60.5 | 48.3 | 6.4 | 44.5 | |

| 2 | 235 | 95.3 | 91.9 | 50.8 | 62.0 | 62.5 | 63.5 | 127.0 | 69.9 | 69.9 | 60.5 | 7.9 | 50.8 | |

| 2 1/2 | 267 | 114.3 | 104.6 | 57.2 | 74.7 | 75.4 | 76.2 | 142.7 | 79.2 | 79.2 | 73.2 | 7.9 | 57.2 | |

| 3 | 305 | 133.4 | 127.0 | 66.5 | 90.7 | 91.4 | 92.2 | 168.1 | 91.9 | 91.9 | 88.9 | 9.7 | 63.5 | |

| 4 | 356 | 165.1 | 157.2 | 76.2 | 116.1 | 116.8 | 117.6 | 190.5 | 108.0 | 108.0 | 114.3 | 11.2 | 69.9 | |

| 5 | 419 | 203.2 | 185.7 | 91.9 | 143.8 | 144.5 | 144.5 | 228.6 | 130.0 | 130.0 | 141.2 | 11.2 | 76.2 | |

| 6 | 483 | 235.0 | 215.9 | 108.0 | 170.7 | 171.5 | 171.5 | 273.1 | 152.4 | 152.4 | 168.4 | 12.7 | 82.6 | |

| 8 | 552 | 304.8 | 269.7 | 127.0 | 221.5 | 222.3 | 222.3 | 317.5 | 177.8 | 177.8 | 219.2 | 12.7 | 95.3 | |

| 10 | 673 | 374.7 | 323.9 | 165.1 | 276.4 | 277.4 | 276.4 | 419.1 | 228.6 | 228.6 | 273.1 | 12.7 | 108.0 | |

| 12 | 762 | 441.5 | 381.0 | 184.2 | 327.2 | 328.2 | 328.7 | 463.6 | 254.0 | 254.0 | 323.9 | 12.7 | 120.7 | |

| Nominal Pipe Sze | DRILLING | BOLTING | APPROXIMATE WEIGHT | ||||||||||||

| Stud Bolt Length | |||||||||||||||

| Bolt Circle Diam, | Number of Holes | Diam. of Holes | Diam. of Bolt (inch) | 0.25" Raised Face | Male- Female Tongue -Groove | Ring Joint | Welding Neck | Slip-on and Threaded | Lap Joint | Blind | |||||

| Kg | lb | Kg | lb | Kg | lb | Kg | lb | ||||||||

| 1/2 | 88.9 | 4 | 22.4 | 3/4 | 120.7 | 114.3 | 120.7 | 3.18 | 7.00 | 3.18 | 7.00 | 3.00 | 6.60 | 3.18 | 7.00 |

| 3/4 | 95.3 | 4 | 22.4 | 3/4 | 127.0 | 120.7 | 127.0 | 4.08 | 9.00 | 4.08 | 9.00 | 3.63 | 8.00 | 4.54 | 10.00 |

| 1 | 108.0 | 4 | 25.4 | 7/8 | 139.7 | 133.4 | 139.7 | 5.45 | 12.00 | 5.44 | 12.00 | 4.99 | 11.00 | 5.44 | 12.00 |

| 1 1/4 | 130.0 | 4 | 28.4 | 1 | 152.4 | 146.1 | 152.4 | 9.07 | 20.00 | 8.16 | 18.00 | 7.26 | 16.00 | 8.16 | 18.00 |

| 1 1/2 | 146.1 | 4 | 31.8 | 1 1/8 | 171.5 | 165.1 | 171.5 | 11.35 | 25.00 | 11.00 | 24.30 | 9.99 | 22.00 | 10.44 | 23.00 |

| 2 | 171.5 | 8 | 28.4 | 1 | 177.8 | 171.5 | 177.8 | 19.07 | 42.00 | 17.25 | 38.00 | 16.80 | 37.00 | 17.71 | 39.00 |

| 2 1/2 | 196.9 | 8 | 31.8 | 1 1/8 | 196.9 | 190.5 | 203.2 | 23.61 | 52.00 | 24.97 | 55.00 | 24.06 | 53.00 | 25.42 | 56.00 |

| 3 | 228.6 | 8 | 35.1 | 1 1/4 | 222.3 | 215.9 | 228.6 | 42.68 | 94.00 | 37.68 | 83.00 | 36.32 | 80.00 | 39.04 | 86.00 |

| 4 | 273.1 | 8 | 41.1 | 1 1/2 | 254.0 | 247.7 | 260.4 | 64.00 | 141.00 | 58.00 | 127.90 | 54.48 | 120.00 | 60.38 | 133.00 |

| 5 | 323.9 | 8 | 47.8 | 1 3/4 | 298.5 | 292.1 | 311.2 | 110.68 | 244.00 | 95.25 | 210.00 | 92.53 | 204.00 | 101.15 | 223.00 |

| 6 | 368.3 | 8 | 53.8 | 2 | 342.9 | 336.6 | 355.6 | 176.46 | 378.00 | 146.51 | 323.00 | 143.01 | 315.30 | 156.63 | 345.30 |

| 8 | 438.2 | 12 | 53.8 | 2 | 381.0 | 374.7 | 393.7 | 261.27 | 576.00 | 219.99 | 485.00 | 213.38 | 470.40 | 240.62 | 530.50 |

| 10 | 539.8 | 12 | 66.5 | 2 1/2 | 489.0 | 482.6 | 508.0 | 484.43 | 1068.00 | 419.57 | 925.00 | 408.60 | 900.80 | 465.36 | 1026.00 |

| 12 | 619.3 | 12 | 73.2 | 2 3/4 | 539.8 | 533.4 | 558.8 | 692.35 | 1526.30 | 590.20 | 1301.00 | 572.95 | 1263.00 | 664.06 | 1464.00 |

Notes:

(1) For the inside diameter of pipes(corresponding to 'Bore' (B1)of Welding Neck Flanges),refer to page 60

(2) Class 2500 flanges except Lap Joint will be furnished with 0.25"(6.35mm)raised face, which is not included in 'Thickness' (t) and 'Length through Hub'(T1),(T2).

(3) For Slip-on, Threaded, and Lap Joint Flanges, the hubs can be shaped either vertically from base to top or tapered within the limits of 7 degrees".

(4) Blind Flanges may be made with the same hub as that used for Slip-on Flanges or without a hub.

(5) The gasket surface and backside (bearing surface for bolting) are made parallel within 1 degree. To accomplish parallelism, spot-facing is carried out according to MSS SP-9, without reducing thickness(t).

(6) Class 2500 Slip-on Flanges are not covered by ANSI B16.5, Slip-on flanges are at the manufacturer's option.

ANSI B16.5 FORGED FLANGES TOLERANCE

| THREAD,SOCKET-WELDING, SLIP-ON,LAP JOINT AND BLIND. | WELDING NECK | ||||

| Outside Diameter | When O.D.is 24"or less | ±1/16"(1.6mm) | Outside Diameter | When O.D.is 24"or less | ±1/16"(1.6mm)* |

| When O.D.is Over 24" | ±1/8"(3.2mm)* | When O.D.is Over 24" | ±18"(3.2mm) | ||

| Inside Diameter | Threaded | Within limits on boring gauge | Inside Diameter | 10"and Smaller | ±1/32"(0.8mm) |

| 20"thru 18" | ±1/16"(1.6mm) | ||||

| Socket-Welding Slip-on and Lap joint | 10"&Smaller +1/32"(0.8mm).0" 12"&Larger +1/16"(1.6mm).O" | 20"and Larger | +1/8"(3.2mm) -1/16"(1.6mm) | ||

| Outside Diameter of Hub | 5"and Smaller | +3/32"(2.4mm) -1/32"(0.8mm) | Diameter of Hub at Base | When Hub Base is 24"or Smaller | ±1/16"(1.6mm)* |

| 6"and Larger | +5/32"(4.0mm) -1/32"(0.8mm) | When Hub Base is Over 24" | ±1/8"(3.2mm)* | ||

| Diameter of Contact Face | 1/16"Raised Face | ±1/32"(0.8mm) | Diameter of Contact Face | 116"Raised Face | ±1/32"(0.8mm) |

| 1/4"Raised Face Tongue & Groove Male,Female | ±1/64"(0.4mm) | 14"Raised Face Tongue &Groove Male,Female | ±1/64"(0.4mm) | ||

| Diameter of Counterbore | Same as for Inside Diameter | Diameter of Hub at Point of Welding | 5"and Smaller | +3/32"(2.4mm)* -1/32"(0.8mm) | |

| 6"and Larger | +5/32"(4.0mm) -1/32"(0.8mm) | ||||

| Drilling | Bolt Circle | ±1/16"(1.6mm) | Drilling | Bolt Circle | ±1/16"(1.6mm) |

| Bolt Hole Spacing | ±1/32"(0.8mm) | Bolt Hole Spacing | ±1/32"(0.8mm) | ||

| Eccentricity of Bolt Circle with Respect to Facing | 21/2"Smaller 1/32"(0.8mm)Max. 3"&Larger 1/16"(1.6mm)Max | Eccentricity of Bolt Circle with Respect to Facing | 21/2"Smaller 1/32"(0.8mm)Max. 3"&Larger 1/16"(1.6mm)Max. | ||

| Eccentricity of Bolt Circle with Respect to Bore | 1/32"(0.8mm)Max.* | Eccentricity of Bolt Circle with Respect to Bore | 1/32"(0.8mm)Max.* | ||

| Eccentricity of Facing with Respect to Bore | 1/32"(0.8mm)Max.* | Eccentricity of Facing with Respect to Bore | 1/32"(0.8mm)Max.* | ||

| Thickness | 18"and Smaller | +1/8"(3.2mm).0^ | Thickness | 18"and Smaller | +1/8"(3.2mm),0" |

| 20"and Larger | +3/16"(4.8mm).04 | 20"and Larger | +3/16"(4.8mm).O | ||

| Length Thru Hub | 10"and Smaller | ±1/16"(1.6mm) | Length Thru Hub | 10"and Smaller | ±1/16"(1.6mm) |

| 12"and Larger | ±1/8"(3.2mm) | 12"and Larger | ±1/8"(3.2mm) | ||

This tolerance is not covered in ANSI B16.5, but maker's option.

STANDARD FINISHES for Face of Flange (ANSI B16.5)

STOCK FINISH:

The most widely used gasket finish.because practically is suitable for all ordinary service conditions. This is a continuous spiral groove. Flanges size 12" (304.8mm)and smaller are produced with a 1/16" round-nosed tool at a feed of 1/32" per revolution. For sizes 14" (355.6mm)and larger. the finish is made with a 1/8" round-nosed tool at a feed of 3/64" per revolution.

SPIRAL SERRATED OR PHONOGRAPHIC:

This finish is produced by using a 90°round-nosed tool.

CONCENTRIC SERRATED:

This finish is produced by using a 90°round-nosed tool.

SMOOTH FINISH:

The cutting tool employed shall have an approximate 0.06"radius.

The resultant surface finish shall have a 125μ inch to 250μ inch(ANSI B16.5 para 6.4;4.1)

1. RAISED FACE AND LARGE MALE AND FEMALE

A serrated-concentric or serrated-spiral finish with 34 to 64 grooves per inch is used.

The cutting tool employed has an approximate 0.06 in.radius.The resultant surface finish shall have a 125μ inch(3.2m)to 500μ inch(12.5μm) approximate roughness.

2. TONGUE AND GROOVE AND SMALL MALE AND FEMALE

The gasket contact surface does not exceed 125μ in. (3.2μm)roughness

3. RING JOINT

The inside wall surface of the gasket groove does not exceed 63μin.(1.6μm)roughness,

4. BLIND

Blind flanges need not be faced in the center if, when this center part is raised, its diameter is at least 1 in. smaller than the inside diameter of the corresponding pressure class fittings. When the center part is depressed, its diameter is not greater than the inside diameter of the corresponding pressure class fittings. Machining of the depressed center is not required.

The manufacturing process of forged flanges begins with the selection of high-quality steel, which is heated and shaped under high pressure in forging dies to enhance its strength and durability. After forging, the flanges are trimmed, heat-treated to relieve internal stresses, and precisely machined to meet the required dimensions. They undergo rigorous inspection and testing for quality assurance, followed by surface treatments for enhanced corrosion resistance. This process results in flanges that are strong, reliable, and suitable for demanding industrial environments.

Company Profile

Dingxiang Country Gu Cheng Forging Company Ltd. is a leading manufacturer in Dingxiang County, Shanxi Province, known as the "Forging Capital of China." Established with a deep-rooted history in forging, we specialize in producing high-quality flanges and forged components for a wide range of industrial applications. Our extensive product line includes ANSI, DIN, JIS, and EN standard flanges and customized forged parts designed to meet specific customer requirements.

Gu Cheng Forging with over 30 years of experience in producing high-quality forged flanges. Including Weld Neck Flange (WN), Slip-On Flange (SO), Blind Flange (BL), Socket Weld Flange (SW), Lap Joint Flange, Plate Flange, and Customized forged flange.

At Gu Cheng Forging, we serve a global market, providing flanges and forged components for industries such as oil and gas, chemical processing, power generation, shipbuilding, and more. We pride ourselves on our ability to deliver tailored solutions, meeting the highest standard of safety, performance, and efficiency.

As a factory, we can tailor flanges based on your specific requirements for size, material, pressure rating, and surface treatment (galvanization, black paint, etc.). By preventing rust and deterioration, the coating enhances the flange's performance, offering long-term resilience and reducing maintenance needs over time.

Dingxiang Country Gu Cheng Forging Company Ltd, strives to be a trusted partner for all your forging needs, ensuring long-term cooperation and mutual success.

Q1: Are you a manufacturer or a trading company?

A1: We are a professional manufacturer with over 30 years of experience in forging flanges. Our factory is located in Dingxiang, China, known as the "Forging Capital." We produce high-quality, customized forged flanges, offering factory-direct pricing and ensuring top-notch quality.

Q2: What types of flanges do you produce?

A2: We manufacture a wide range of forged flanges, including:

Weld Neck Flange (WN)Slip-On Flange (SO)Blind Flange (BL)Socket Weld Flange (SW)Threaded Flange (TH)Lap Joint FlangePlate FlangeAll our flanges comply with international standards such as ASME, DIN, JIS, and BS.

Q3: What materials do you use?

A3: We offer flanges in a variety of materials, including:Carbon SteelStainless SteelAlloy SteelEach material is sourced from certified suppliers, ensuring durability and performance in diverse industrial applications.

Q4: Can you provide customized flanges?

A4: Absolutely! As a factory, we specialize in customization. We can tailor flanges based on your specific requirements for size, material, pressure rating, and surface treatment (galvanization, black paint, etc.).

Q5: How do you ensure the quality of your products?

A5: Quality is our top priority. Every flange undergoes a strict inspection process, including:

Material analysisDimensional checksPressure testingSurface treatment inspectionsOur CNC machining ensures precise dimensions, and we adhere to strict international standards throughout the manufacturing process.

>> Two-Stage Compression Screw Air Compressor 15kw Permanent Magnet Frequency Screw Air Compressor with Two Stages Air-Compressors

>> NdFeB Magnet Most Popular Kitten Animal School Stationery Whiteboard Discount Price

>> High Quality Universal Z3050 Metal Hole Arm Hydraulic Radial Drilling Machine with CE

>> Gdshowow Remote Control Speed Poop RC Hobby Jacko Toys R/C Poo Toy

>> Casual Sports Backpack Zipper Travel Laptop Backpack Tyvek Paper School Backbag

>> Tungsten Alloy Versatile Fishing Weight Sea and Lake Fishing

>> Heavy Duty CNC Lathe Machine Ck61125b Semi Protection Turning Lathe Center

>> ZY1 Desktop Booklet Maker machine

>> Industrial V Bank Filter F8 F9 F7 ABS Plastic Frame Air Filter

>> High Quality Adjustable Viola Case 15"-17" (SAC102)

>> Factory Price Plastic Crusher Can PS PP Idpe PVC HDPE Pet Bottle Crushing Machine

>> Automatic Rotary Two Colour PVC Rain Boot Production Line

>> cheaper combine Corn cob sheller and thresher machine

>> FRP water reverse osmosis membrane pressure vessel reverse osmosis water system

>> Static Mixer Motionless and Movable Element Mixing Inline Pipe Mixer Wastewater Treatment

>> Train Railway to Budapest Railway Shipping to Europe Custom Clearance EU Shenzhen Guangzhou Shipping Agent Road Freight

>> 650W Sparkler for Wedding and Events

>> Custom Colorful Printing Logo Paper Sleeve Japanese Bamboo Sushi Chopsticks

>> 500 Degrees Thermal Salt Parabolic Solar Concentrator Provide Installation and Commissioning Services

>> Dr. Bang Support Video Cutting of CNC Rubber Cutting Machine Gasket Cutter Automatic Gasket Cutting Machine

>> Taijia OGM series Electronic Flowmeter Oil Flow Meter Manufacturers Flow Meter Fuel Digital Flow Meter For Oil

>> Factory Wholesale 100% Polyester Single Layer Soft Flannel Coral Polar Shu Velveteen Minky Blanket/Throw Printing Design

>> Custom Enamel Pins with Unique Designs for Collectors and Events

>> Electric 3kw Floor Grinding Machine for Concrete

>> Metal Universal Vertical Turret Milling Machine (X6323A X6325D X6330 X6333)

>> Large Size 2000mmx3000mm Woodworking Router Machine CNC Cutting Engraving Machine for Furniture Office Tables Chairs Making with Spindle 10m/Min

>> Haasbelts Conveyor Magnetflex Chainbelt Flat Top 1060 Series

>> China Vegetables Frozen Green Spring Onion Rings IQF Onion Diced/Sliced/Chunk Factory Supplier

>> High Quality HSS-E Roll Tap Without Oil Groove DIN371/376 M4*0.7

>> Sheep casing cleaning machine / Hog Casing Cleaning Machine / scraping intestinal machine