Extrudation compound fertilizer granulating machine

| US$11,111.00 | 1 Piece (MOQ) |

Basic Info.

Model NO.

DH series

Type

Pressing Granulator

Object

Fertilizer

Material

Alloy

Size

Medium

Certification

CE, ISO 9001

Condition

New

roller dimeter

360/450/650/850/1050

granular size

2-5

Main unit power

90-110

Voltage

380V

Motor

55KW

Auctomatic Control

Auctomatic

Frequency Inverter

VFD control

Water Required

1%

Final Granules Shape

Irregular

Recycle Granulating

Recycle

Application

Mineral powder

Hydraulic system

Hydraulic compaction

Capacity

1t/h 2t/h 3t/h5t/h 10t/h

Transport Package

Wooden Case

Specification

DH SERIES

Trademark

fuyi

Origin

China

HS Code

8474801000

Production Capacity

500PCS/Year

Packaging & Delivery

Package Size

2100.00cm * 1600.00cm * 2600.00cm

Package Gross Weight

10000.000kg

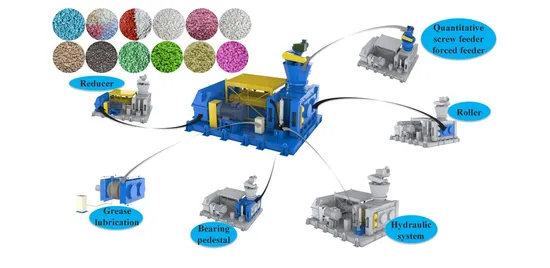

Product Description

Introduction DH series dry roll press granulator adopts dry rolling technology to compress the powdery materials with moisture content ≤ 5% into pieces or tablets, then going through the processes of breaking into granules and screening to make the lump materials into granules that meet the requirements of application. Dry roll press granulator mainly depends on the manner of external pressure to force the material going through the gap between two relatively turning rollers to compress into laminar particles. During course of roller pressing, the real density of materials can increase 1.5~3 times thus reaching certain demands of granular strength.. Applied materials:

1.Fertilizers: Potassium sulfate, Potassium chloride, Ammonium sulfate,Ammonium chloride, Russian Red potash, Potassic fertilizer, NPK, Potassium nitrate, Manheim SOP, MAP, DAP, Ammonium bicarbonate, Ulexite, Phosphate rock.

2.Powders: White carbon black, Zinc sulfate, Clay, Bentonite, Coco peat, Antioxidant, Bromochlorohydantion,Sodium formate, Potassium permanganate, Wormcast, Sodium cyanide, Sodium dichloroisocyanurate, Cyanuric acid, Calcium hypochlorite, Calcium oxide, Limestone, Brown coal, Zinc oxide, Steel slag, Lead oxide, Strontium sulfate, Potassium carbonate, Carbonate strontium, Calcium chloride, Dicalcium phosphate, Sodium metasilicate, Sodium silicate, Cryolite, Aluminum fluoride, Aluminium oxide, Rubber additives, Silica, Calcium aluminate, TSP, SSP, Carnallite stone, Metal powder, Fillers, Feed additives, Nicotinic acid, Nicotinic acid amine, Pharmaceutical intermediates, Steel-making additives, Melting agent, Swelling, Alumina powder, Desulphurized gypsum, Environmental protection materials. etc.

Granules picture

Working process

1). Use belt scales to weigh each raw material according to formula.---Batching system

2). Use mixer to the raw material for more uniform feeding.---Mixer

3). Use bucket elevator lift the material up to the silo.----Bucket elevator and Silo

4). The DH SERIES COMPACTOR compress the raw material by double rollers, it mainly depending on the mechanical pressure to compress the dry powder, so the hardness of granular is very high.---------DH SERIES compactor (including three parts: dosage screw feeder, forced feeder and flaking machine.)

5). Then we get the bar shape products.

6). So we need a crusher to crush the bar shape products into 2-4mm irregular granules.----Crusher (you can decide the size of granules, we will design the size of crusher mesh.)

7). Finally, we will use rotary screen to sieve the final products, the unqualified products, such as dust, big granular and very small granular will be recycled for the next time granulation process. You will get the qualified 2-4mm irregular shape granules successfully.--------Rotary Screen

8). Next we use the second time rotary screen, the purpose is we want to get better result of irregular shape granules after second time screening, the appearance of irregular shape granular will looks more beautiful. -------Second Time Rotary Screen (if you don't need this, you can delete this process.)

9).After second sieve, the granule enter into the rotary drum for coating.You can spray some liquid or powder on the surface of the particles to avoid clumping.-------Coating machine

9). The last step is packaging machine. This machine will help you pack the final granular into bags. ---You can choose 25-50kg/bag Packaging Machine or TON-package machine(800-1000kg/bag)

10). Workshop dusts mainly come from the crusher, screening and discharging port of bucket elevator, in order to effectively remove the dust, this process uses two stages of dust removal. A cyclone dust collector is used to remove the larger particle dust, and then the bag dust filter is used to remove the residual dust. The dust from the dust collector will return to the granulation process by scraper conveyor.------ Dust collecting process.

| Model | DH360 | DH450 | DH650 | DH850 | DH1050 |

| Roller diameter (mm) | φ360 | φ450 | φ650 | φ850 | φ1700 |

| Roller speed (rpm) | 10-25 | 10-25 | 10-25 | 9-16 | 8.5-14.5 |

| Max rolled sheet thickness (mm) | 8 | 12 | 16 | 25 | 36 |

| Finished product output (Kg) | 900-1300 | 1800-2500 | 3500-4000 | 6000-8000 | 12000-16000 |

| Granular size (mm) | 2-5 | 2-5 | 2-5 | 2-5 | 2-5 |

| Main unit power (KW) | 30-37 | 55-75 | 90-110 | 220-250 | 400 |

| Total installed capacity (KW) | 55 | 90 | 175 | 400 | 850 |

| External dimension (mm) | 2350×2000×2600 | 2600×2200×2900 | 3600×2800×3200 | 5000×3800×4100 | 5500×6400×4800 |

| Total weight (t) | 7 | 10 | 21 | 46 | 98 |

Feature

Granular strength can be adjusted by adjusting the pressure of roller, control strength of final products.

Cycle operations to achieve continuous production. High yield of finished products.

Materials are force to compress molding by mechanical pressure, without any additives, the product's purity is guaranteed.

Dry powders are granulated directly without follow-up drying process, the existing production process is easy to convergence & transformation.

Granular strength is high, compared with other granulating methods, the improvement sof bulk density are significant,especially for the occasion where increase the proportion of product accumulation.

A wide range of raw materials can be used, granular strength can be freely adjusted according to different materials.

Compact structure, easy maintenance, simple operation, short process, low energy consumption, high efficiency, low failure rate.

Control environmental pollution, reduce waste and powder packaging costs, and improve product transport capacity.

Feeding device adopts frequency adjustment control, high automation ,one can control multi-machine, has the features of low labor intensity and long term continuous operation,etc.

Major transmission components use high quality alloy material. stainless steel, titanium, chromium and other surface alloys which greatly improved wear resistance, corrosion resistance, high temperature and pressure capabilities, so that this machine has one long service life.

Layout

Customer installation site

Service

Q&A

>> Anon Hand Reaper Combine Binder Harvester Mini Crops Reaper and Binder

>> 9kwh420 8-12t/H Good Quality Animal Feed Pellet Plant

>> PVC EVA ABS Floats Apple Floats New Type (DSAP-01)

>> Tractor Mounted 3 Point Machines Pto Driven One Row Sweet Potato Harvester

>> Precision CNC Turn Milling Machining Custom Aluminum Auto Parts Car Interior Door Handle

>> Bordadora T-Shirt Beads Single Head Computerized Embroidery Machine Prices

>> Qingdao Haocheng Polyvinyl Butyral PVB Resin for Film

>> Low-cost EN12830 resuable temperature humidity datalogger with automated PDF reports TempUsb S3

>> 48V 200ah 100ah Lithium Battery Packs Solar Generator UPS Lithium Ion Battery

>> 52cc Mini Gasoline/Petrol Power Rotary Weeder Tillers for Farm Agricultural Ploughing Machine Cultivator

>> Newest Rtx 3070 3080 3090 3060 10g 12g 24G Rtx3080 Ti 3080 Graphics Cards GPU 320bit in Stock

>> Rotary Table Lifting Table Metal Machine Tool X6140 Horizontal Universal Milling Machine

>> 4 cavity semi automatic pet bottle blow blowing molding machine for filling line

>> Baoli Children′s Electronic Grand Piano with 37 Keys, Interactive Learning Piano Toy with Instrument Sounds and Microphone

>> Disposable Plastic PP Yogurt Cup Aluminum Foil Lids

>> 5-Htp 5-Hydroxytryptophan Griffonia Seed Extract 99%

>> Retro Chandelier Hanging Wire Hanging Aluminum Lamp Head E27 Large Screw Lamp Holder

>> Nylon /Polyester Knotted Nets, Add UV Protection, High Strength, 210d/24ply 100MD Green Color, Multifilament Fishing Net, Pano Redes De Pesca

>> Factory Price Mini Passive Optical Splitter Steel Tube 0.9mm Sc/APC 1X8 Fiber Optic PLC Splitter

>> Chinese Pink Electric Golf Cart 4 Seater Golf Cart 72V Sightseeing Bus Electric Vehicle Electric Small Car Mini Car 2 Seater Buggy Lifted Electric Golf Car ISO

>> Dr System Printer for Thermo-Graphic Film Processor

>> Fiber Opener Silicone Polyester Fiber Opening Carding Recycling Machine Pillow Filling Machine

>> Wholesalers Recessed 7W Round Ultra Thin Hot Sell LED Panel Light

>> Premium China Urea Phosphate Fertilizer

>> Jst pH 2.0mm 2.5mm 2 Pin 3pin Male and Female Battery Extension Cable Wire

>> Customize Wholesale Bamboo USB Flash Disk Promotion Gift USB Memory Stick

>> Full automtic food processing commercial mini nut sesame cocoa milling grinder production line grains grinding colloid mill soybean peanut butter making machine

>> Excavator Hydraulic Alligator Shear Hydraulic Shears for Excavators

>> 4cm Raschel Elastic Small Flowers Lace Trim for Undergarments

>> Modern High-End Business Furniture Movable Folding with Wheels Combination Office Conference Training Table