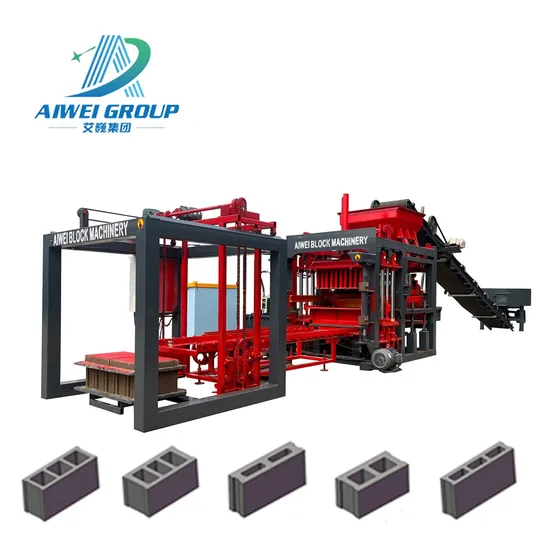

Qt4-15b Brick Machine Making Automatic of China Manufacturer Factory Price

Basic Info.

Model NO.

QT4-15B

Certification

CE

Customized

Customized

Automatic Grade

Automatic

Type

Hydraulic Shock

Weight

5200kgs

Brick Raw Material

Concrete, Cement, Sand, Gravel, Fly Ash

Voltage

220/240/380/440V(Custormed)

Brick Size

400*100*200 mm, 400*150*200 mm, 200*100*60 mm...

Vibration Force

65-75kN

Brand Name

Aiwei

Hydraulic Press

21MPa

Power

31.2kw

Cycle

15-20s

Products

Hollow/Solid Blocks, Colored Pavers, Houdis, Curb

Related Mixer

Jq500 Mixer and 1000 PCS Pallet

Key Selling Points

Easy to Operate

Production Capacity (Pieces/8 Hours)

7720 PCS/8hours, 8500 PCS/8hours, 22000 PCS/8hours

Method

Vibration

Color

Optional

Transport Package

Plywood Box with Iron Frame

Specification

4300*2150*2650mm

Trademark

AIWEI

Origin

Shandong, Linyi

HS Code

8474802000

Production Capacity

7720 PCS/8hours, 8500 PCS/8hours, 22000 PCS/8hours

Packaging & Delivery

Package Size

450.00cm * 215.00cm * 265.00cm

Package Gross Weight

3200.000kg

Product Description

Product Description| Qt4-15B Paving Block Making Machine High Quality Semi Automatic Concrete Cement Brick Pressing Machine |

1.QT4-15B is a medium sized full automatic hydraulic system brick production line

2.New design and new technology,it could produce faster and better quality bricks

3.Produce different size hollow block,solid block,interlocking block,paving brick and curb stones by changing molds

4.We can supply block machine with different color, such as blue, green, red, orange, black, yellow etc. and we can also

print logo or word on machine as your requirement.

Detailed Photos

| Main Parts |

Solenoid valves

Imported hydraulic solenoid valves are used to ensure reliable operation of the hydraulic system and extremely low failure rate.

PLC Control System

Function:PLC is a remote control system used to replay relay,executive logic and other sequential control functions.

Advantage:PLC has the characteristica of strong universality,convenient use,wide adaptability,high reliability,strong anti-interference ability and simple prongramming.

Stacker:

power:3KW

Put the cartons packed in containers on the pallet according to a certain arrangement,stack them automatically,and then push them out,which is convenient for forklift transportation.

Block mould Function:Comprise an upper die and a lower die,and that interaction between the upper die and the low die prevents the periphery of the punched material from being deform.

Advantage:After carbonization and wire cutting technology,the mold is more wear-resistant and has a longer service life.

JQ500 Mixer:Stir evenly and thoroughly, without residue, simple structure, simple operation, fast discharging speed, sturdiness and durability, long service life, and convenient maintenance.

| Technical Specification |

| Power | 31.2KW |

| Cycle | 15-20S |

| Vibration Force | 60-75KN |

| Rated Pressure | 21Mpa |

| Pallet Size | 1010*550*25mm |

| Machine Size | 4300*2150*2650 |

| Weight | 5200KGS |

| Worker | 5-7 Workers |

| Related Accessories | 100T Silo, PLD1200 Batching, JS500 mixer, Forklift, 2000pcs Pallet |

| Production Capacity |

Package&Delivery

1.Packing:Seal the whole body with plastic wrap and put it in ironform plywood box.

2.Terms of delivery:From our factory to Qingdao Port,China

3.Guarantee:A warranty period for the Machine is 12 months.

Company information

Our Services

1.Before-sale services:

1)Guide customers to choose the best appliable machine type;provide the advanced,energy-saving and practical technological process.

2)We are responsible for the process chart and design.

2.Sale services:

1)Products must be inspected strictly before selling.

2)In accordance with the agreements stipulated in the contract.

3)We will organize delivery.

3.After-sale services:

1)Our company will send professional engineers to guide eith device installation,debugging and training operators until customers are fully satisfied.Moreover,we will design and manufacture products,according to the special requirements of customers.

2)Because of the problems caused by quality rather than human factors,we repair them free of charge.The quality guarantee period for machines is one year except the wearing parts.

>> Modern House Design Sun Shade Louvers Roof Waterproof Outdoor Pergola Aluminum

>> New Arrival Skmei 1783 Black Quartz Watch for Lady Women Wristwatch Leather Strap Wholesale Price

>> Furniture Hardware Metal Creative Three-Legged Sofa Leg

>> Byloo Metal Jigging 80mm 3 5 7 10 15 20 25g Artificial Bait Boat Fishing Jig Lures Super Hard Spoon Lead Fish Fishing Lures

>> M1050A Manual Operation Grinding Machinery

>> Taijia transmitter digital portable ultrasonicwater flowmeter handheld ultrasonic flowmeter

>> 4.5X16 Spoke Wheel Assembly and Semi-Pneumatic Polyurethane Tire

>> High Quality Sponge Pad

>> Self Propelled Concrete Mixer Truck 5cbm Tourfine for Easy Operation

>> Xn32 Vertical and Horizontal Universal Milling Machine Original Manufacturer

>> Microfiber Lining Material Anthracite Fitting Stylish Fashion Designer Unisex Genuine Leather Sunglasses Case Supplier

>> Lint Free Green Pink Yellow White Laboratory Suits Reusable Anti Static Washable ESD Antistatic Coverall

>> 500 Kg/Hr Patented Powder Coatings Compact Drum Cooler

>> Ultra-Thin Pure Color Low Rise Sexy Fashion Thong Nude Feeling Quick-Drying Breathable Soft Stretchy Yoga Underwear

>> Wholesale Custom Colored Unicorn Cartoon Animal Promotion Gift Custom Plush Toy Stuffed Animal Toys

>> New Spray Gift USB Flash Disk

>> High Quality Waste PP PE Plastic Film Crushing Recycling Line Recycling Machinery

>> Lincheng High Quality Semi-Automatic Stitching Machine Lum-B 2000/2500/3000

>> Fashion Designer Reversible Woman PU Leather Tote Bag Ladies Handbag

>> Poultry Processing Chicken Slaughter Line - Stainless Steel 304 Construction

>> Butterfly Valve Pn16 Dn150-Dn1800 Double Flange Double Eccentric Soft Sealed BS5163

>> Karting Car Racing Driving Game Machine Car Simulator

>> Small Laboratory Ultrasonic Homogenization for Graphene Dispersion

>> 12mm 18mm 24mm Double Sided Adhesive Tape for Gluing Cardmaking Boxes

>> Brass pipe nipple pipe fitting reducing tee joint tube pipe fitting connector

>> Single Head High Speed Automatic Factory Multifunctional Computerized Embroidery Sewing Machine Kqm with Embroidery Machine in China

>> Almost Used PC200 Crawler Excavator PC200-7 PC200-8 Good Condition

>> Electric Collapsible Folding Utility Outdoor Camping Garden Cart

>> High Quality Custom Men Thick Winter Cashmere Scarf Fashion Plaid Pashmina Shawl Scarf with Tassel

>> Capacitive Touch Screen WiFi Android Network Windows Self Service Kiosk for Restaurant