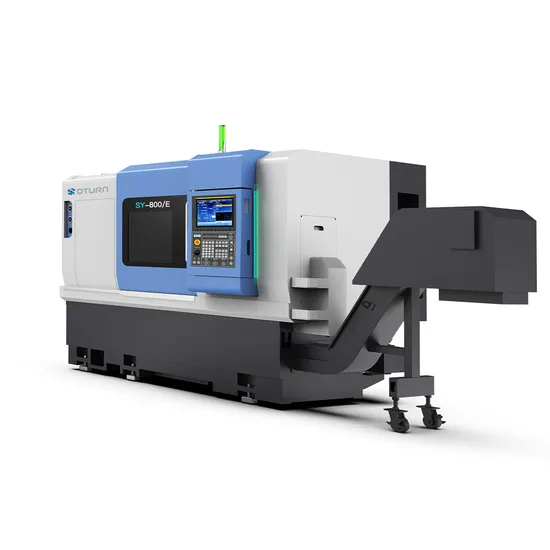

Professional High Precision CNC Machine Tools Metal CNC Lathe Slant Bed Lathe Esy800

| US$28,500.00-182,000.00 | 1 Set (MOQ) |

Basic Info.

Model NO.

ESY800

Type

Turret Lathe

Processing Accessory

Chuck CNC Lathe

Guide Rail

Inclined Guide Rail

Tool Holder

Single-tool Holder CNC Lathe

Power Source

Electric

Controlling Mode

CNC

Automatic Grade

Automatic

Setting Mode

Floor-type

Precision

High Precision

Certification

GS, CE, ISO 9001

Condition

New

Control System

Fanuc, Siemens, Mitsubishi

Spindle

A2-6,A2-8,A2-11

Chuck

6,8,10,12inch

Tool Turret

Vdi or Bmt

Motor Power

11,15,18.5,22kw

Transport Package

Plywood Case

Specification

3500*2110*2100

Trademark

Oturn

Origin

China

HS Code

8458110090

Production Capacity

1000/Year

Product Description

Product Description

1. The spindle unit system has undergone strict dynamic balance testing and has high accuracy, good accuracy retention, small thermal deformation, and good thermal stability. The spindle's large aperture Φ79 can reach a maximum speed of 4000rpm, and the nose deflection accuracy is within 0.003MM. The front end of the shaft uses a large-diameter, high-precision double-row roller bearing with a combined angular contact ball bearing structure. The optimal span two-point balance support design can withstand radial and axial loads, and can also provide users with high-speed precision work. It can also perform low-speed and heavy cutting, and is especially suitable for mass production of products with complex shapes, high precision requirements, and high smoothness.

2. High rigidity overall design servo turret. Equipped with a high-precision clutch to ensure its positioning accuracy and repeatable positioning accuracy. It is equipped with a servo motor to drive the cutterhead to rotate for bi-directional or arbitrary tool selection. The hydraulic principle is used to loosen and clamp the clutch, and the proximity switch feedbacks the clutch action signal to quickly and accurately achieve the tool change action.

3. The machine tool is equipped with THK linear guide rails and ball screws. The heat-treated and precision-ground ball screws can ensure the best accuracy and durability. Each axis adopts a direct transfer axis structure and a double-anchor pre-relay method to prevent thermal changes. The bit quantity will be reduced to the minimum, greatly improving the processing accuracy. The high-rigidity, large-sized, heavy-duty linear slide rails maintain intact accuracy when the machine is subjected to impact, and the displacement is smooth and low-noise, which can extend the service life.

4. This machine provides users with a complete hydraulic and lubrication system, using high-quality hydraulic pumps, hydraulic valves and other components to greatly reduce the failure rate. The hydraulic and lubrication systems are designed to be simple and reliable. The machine tool adopts centralized quantitative automatic lubrication.

5. The hydraulic tailstock has a high-rigidity structure and an integral tailstock, which can eliminate vibration and provide excellent stability. The sleeve is telescoped using a hydraulic cylinder, which is convenient and reliable.

6. It adopts Taiwan rotary chuck cylinder and is equipped with an automatic chip removal device, which can greatly reduce the labor intensity of the operator and achieve safe and efficient production. The above functional components can be programmed and controlled, and various components can be designed and installed according to the special requirements of the user. A special fixture. Product Parameters

| Name | Unit | SY800/E | |

| Travel | The largest diameter rotating bed | mm | Φ700 |

| Max. processing diameter | mm | Φ650 | |

| Max.Swing Over Cross Slide | mm | Φ350 | |

| Max. processing length | mm | 790 | |

| Spindle Hydro cylinder Chuck | Spindle nose | type | A2-6 |

| Max. speed of spindle | rpm | 4000 | |

| Hydraulic Cylinder /Chuck | lnch | 10″/8″ | |

| Spindle hole diame | mm | Φ79 | |

| Bar diameter | mm | Φ65 | |

| Spindle motor power | kw | 15/18 | |

| Spindle motor torque(1:1.4) | Nm | 134-196 | |

| X/Z axis feed | X/Z axis travel | mm | 350/960 |

| X/Z axis rail specification | spes | 45 | |

| X/Z axis shaft wire specifications | mm | 4012 | |

| X/Z axis motor power | kw | 2.9 | |

| Positioning accuracy | mm | ±0.005 | |

| Repeat positioning accuracy | mm | ±0.003 | |

| X/Z axis moving fast | m/min | 24/24 | |

| Servo Tutter | Tool position | pcs | 12T |

| The Tool biock specifications | mm | 25X25 | |

| Inner diameter tool holder specifications | mm | Ф40 | |

| The adjacent tool change time | sec | 0.2 | |

| Positioning accuracy | / | ±2" | |

| Repeat positioning accuracy | / | ±1" | |

Tail stock | Programmable hydraulic tail seat | / | Hydraulic tail seat |

| The biggest stroke of the tail | mm | 630 | |

| Morse Slide way | type | Mohs 5# | |

| Sleeve diameter | mm | Ф100 | |

| Sleeve travel | mm | 100 | |

| Mechanical Size | Machine size | mm | 3500*2110*2100 |

Products Configurations

Company Profile

Quality Control

Our Advantages

FAQ

Q1:How can l choose the most suitable machines ?

Please tell me your specications,we can choose the best model for you,or you can choose the exact model,you can also send us the products drawing,we will choose the most suitable machines for you .

Q2: What's your main products of your company?

We specialized in all kinds of machines,such as CNC Lathe Machine ,CNC Milling Machine,CNC Turning Maching,Vertical Machining Center ,Horizontal Machining Center,Lathe Machines,Turning and milling composite processing so on.

Q3: Where is our factory located? How can l visit there?

We have 5 factories located in Guangzhou, Quzhou, Ningbo, and Guangdong.You are warmly welcomed to visit us.

Q4. How do you transport it?

Provide Transportation Solution DDP/CIF/FOB/FCA

Q5: What's the Payment Terms ?

T/T ,30% initial payment when order,70% balance payment before shipment .

06: What's the MoQ?

A: 1 set .(Only some low cost machines will be more than 1 set )

We want to know:

1.We strongly suggest you to tell us size, material of your workpiece for our evaluation if possible, better to send us workpiece drawing, so that we can recommend you most suitable model!

2.lf need ClF Price, please kindly tell us the port of destination.

>> Automatic Intelligent Rotary Type 30 Station PU TPU Injection Machine

>> Lifetime warranty CE making machine Hurricane Storm Slide Double Glaze White UPVC european windows

>> FRP Pultrusion Profiles Production Machine Kinds of Profiles Production Line

>> Comfortable Wholesale Vest Made to Order Sportswear.

>> MR-13D industrial easy work drill sharpening machine with CBN wheel

>> PVC PP Brass Insert Thread Pipe Fitting Injection Mould

>> Factory Wholsale Lowest Price 12V 24V AC Hose Crimping Machine

>> Popular Heavy Duty Dongfeng Tianlong 25000kg Compactor Garbage Truck Efficient Waste Disposal Large Diesel Compression Special Vehicle Best Quality 5250

>> Yada Biodegradable Disposable Wooden Flatware Fork Knife Dinnerware Weddings Wooden Spoon Knife Forks Set For Fast Food

>> New Technology 2850mm Crescent Type Toilet Tissue Paper Machine

>> Hot Selling Dried Corn COB Pellets Natural Corn COB Powder Corn COB Meal for Animal Feed Low Price for Sale

>> Mini Industrial PC J5005 2LAN I225 DDR4 2COM Computer Mini 2USB VGA HD Display DC 12V Fanless Computer PC

>> FUJI China Goods Elevators Ang Freight Elevators

>> Casement Door for Wc Bathroom Door Price Bangladesh Aluminum 3D Model Design Graphic Design Modern Commercial Rolling 3 Years

>> High Pressure Homogeneous Mixing Equipment Penis Enlargement Cream Vacuum Homogenizer Mixer Machine

>> for Volv0 V70 Mk2 2001-07 Rear Windshield Wiper Motor Windscreen Metal

>> ML1100 Industrial Die Cut Machine Carton Paperboard Die Cutter Manual Paper Die Cutting and Creasing Machine

>> Hot Sale! 20 Ton Used Cat 320d Digger Second Hand Cat Excavators for Sale - Ready to Work!

>> Chinese Supplier Since 1995 Semiautomatic Block Moulding Machine Dakar Supplier

>> Hot P866-a Kids Engineering Backpack Construction Truck Parking Lot Toy

>> Small Flat Wire Steel Metal Coil Wave Spring

>> Kids Wear Factory Wholesale Solid Color Blank Shorts Girls Fleece Shorts with Floral Edges Solid Cotton Shorts for Baby Girls Clothes

>> Promotion Gift 6 Hexagonal Mini Color Pencils 3.5 Inch in Natural Craft Paper Tube with Sharpener Cover

>> TOP Quality YGK 91m Fluorocarbon high strength abrasion resistant reel YGK WAKER N380 fishing line

>> Ck6180-1500 High Speed Five Axis CNC Horizontal Vertical Machining Center Milling Machine Large Machining Center Metal Lathe

>> V003 2.4GHz LED Lighting 30km/H High Speed Racing Boat Fast Capsize Recovery Auto Driving RC Boat for Pools and Lake with Water Cooling Protection

>> Cosmetic Grade Triethoxycaprylylsilane Treated Ci 77491 Iron Oxide Red

>> Baby Pant PRO Max for 1000 PCS/Min Speed

>> 10W/20W/30W/50W/100W/150W/200W SMD Outdoor Floodlight LED Flood Light

>> Vietnam Popular Model Biomass Wood Chipper in 2023