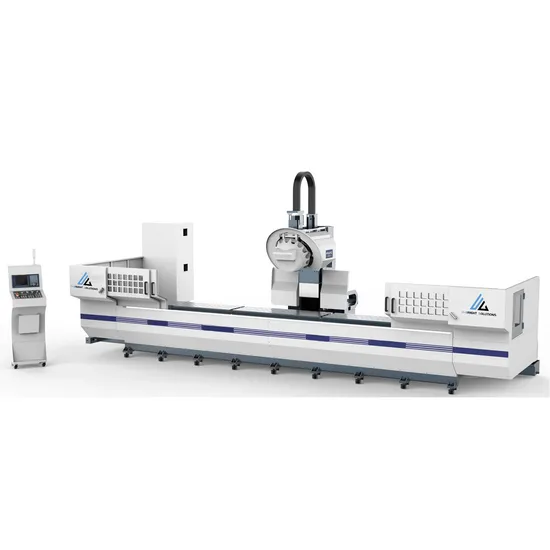

Automatic Heavy Duty Column Machining Center Moving Gantry Milling Machine Center

| US$5,500.00-19,000.00 | 1 SET (MOQ) |

Basic Info.

Model NO.

PIC-CNC4500

Type

Knee-and-Column Milling Machine

Object

New Energy Vehicle Battery Trays

Structure

Bed type

Milling Cutter Type

Vertical Milling Cutter

Milling Cutter Structure

Indexable Type

Controlling Mode

CNC

Automatic Grade

Automatic

Precision

High Precision

Certification

GS, CE, ISO 9001

Condition

New

Taper Hole of Spindle

Bt30 Od: 100mm

X Route or Distance of Travel

2500-6500 (Other Length)

Y Route or Distance of Travel

450mm

Z Route or Distance of Travel

400 mm

Operating System

Fanuc Siemens

Transport Package

Plywood Case

Trademark

Ubright

Origin

Cn

HS Code

8457101000

Product Description

Product Description

The machine for column mobile processing center, the whole machine adopts moving column, ensure the overall rigidity and compact structure, machine rigidity is good. Easy to dispose of scraps and drainage. Good precision retention, can be used for precision cutting;automotive, textile, window frame, civil aviation, motor, valve and other industries.

Applied to new energy vehicle battery trays, rail transit, mechanical manufacturing, and sheet metal processing

The PIC series is mainly used for custom home handles, radiators, TV bezels, car luggage racks, sunroof rails, trims

BT30 tapered spindle bore for the whole series, spindle outer diameter 100mm

Equipped with automatic cooling system

Equipped with disc type 16 tool magazine capacity

Large table travel, large working area, can be processed while loading

Product Parameters

| route or distance of travel | X route or distance of travel | 2500-6500 (other length) |

| Y route or distance of travel | 450mm | |

| Z route or distance of travel | 400mm | |

| principal axis | main shaft speed | 12000rpm (24000rpm electric spindle) |

| taper hole of spindle | BT30 OD: 100mm | |

| tool magazine | Knife library form | Flying saucer style |

| Knife library capacity | 16 pcs | |

| Adjacent change knife time | 2 sec | |

| translational speed | X axis shift | 60 m/min |

| Y axis shift | 28/40 m/min | |

| Z axis shift | 28/40 m/min | |

| Cut into give speed | 15000 mm/min | |

| operating system | FANUC | SIEMENS |

| Spindle drive motor | 5.5 kw | 7 kw |

| X/Y / Z drive motor | 3.0/1.8/1.8 KW | 2.7/2.7/3.1 KW |

| lube oil system | self-lubricate | |

| coolant passage | injection water cooling | |

| definition | X axis positioning is accurate | 0.05 mm (Rating 0.01mm) |

| The Y / Z is positioned precisely | 0.02 mm | |

| Repeat repeat precision (X / Y / Z) | 0.01mm | |

| rating of machine | Pressure demand | 6 kg/cm² |

| altitude | 3300 mm | |

| floor space | 4600-9000*2500 mm | |

| weight | 7000-11000kg | |

Applications

>> 2022 Heavy Duty Large 2 Person Soft-Spun Polyester Spreader Bar Rope Hammock

>> Factory Price Concrete Mixer Truck 3- 12 Cubic Meters

>> Economical 6 Axis CNC Machining Lathe Swiss Type for Metalworking Slm326m-4

>> SS hydraulic Olive oil press machine/olive oil extraction machine

>> Waste Anti-Wear Hydraulic Oil Treatment Equipment Waste Lubricating Oil Treatment Machine Oil Purifier Reduce Environmental Pollution

>> 4.8"X7.2"/12X18cm Light Green Glossy Decor Wall Tile Glazed Kitchen Ceramic Tile Decoration

>> Tostone Italy Bianco Carrara White Elegant Light Grey Marble Fan-Shaped Mosaic for Home Decor

>> Aluminum Profile Three-Side Flip CNC Drilling and Milling Machine Intelligent and Easy-to-Operate Window Drilling Machine

>> OEM Whole Sale Unique Retro Fashion Customized Acetate Sunglasses for Unisex

>> Marvell Chip 10/100/1000m 8 Port Poe Switch with 1 Uplink SFP Port

>> Auto Spare Parts Inner Fender /Wheel Liner/ Under Cover

>> Fiber Opening Carding and Plush Toy Stuffing Filling Machine

>> CATsolenoid valve 121-1491/457-9878 is suitable for 312D L, 314C and other excavators.

>> Fd30 Vertical Sand Mill and Grinding Mill Machine

>> Wholesale quality burgundy sexy leggings high waist seamless butt lifting waist training yoga pants with pocket

>> Yongbo Ruian High Speed Paper Cup Forming Machine Yb-Wt70

>> Feed Grade Food Grade Pharma Grade Ferrous Fumarate with Good Quality

>> Ultra Light Best Selling Badminton Racket for Regular Play

>> High Quality Auto Engine Oil Filter 26300-35505 26300-35500 26300-35503 26300-35504 for Engine Protected Hyund

>> CE Standard Plastic HDPE Shampoo Bottle Grinder Washing Recycling Machine

>> Multifunctional Hot Sale Xiaomi Dreame V9 20000pa Rechargeable Wireless Handheld Vacuum Cleaner

>> High Supportive Cervical Pillow Memory Foam Sleeping Pillow

>> High Quality Semi Automatic Plastic Rubber Neoprene Ultrasonic Weld And Cut Machine

>> The Best and Cheapest Large Corian Slabs with Artificial Translucent Stone for Vanity Top

>> CNC Part Stainless Steel Metal Machinery Motorcycle Auto Parts Custom Machining

>> New Tder Small Digger Micro Bagger Mini Excavadora 1 2 2.5 Ton Crawler Excavator Prices

>> Hydraulic EVA Raw Material Press Cutting Machine (hg-b30t)

>> One Station Non Woven Interlining Fusible Interlining Water Soluble Interlining Woven Interlining Embroidery Backing Garment Accessory Tailoring

>> High Efficiency Worm Gear Series Double Enveloping Worm Gear Unit Worm Gearbox

>> Ergonomic Adjustable Office Swivel Chair for Comfort Livable Office and Leisure Chairs