Automatic Non-Woven Disposable Cotton Tissue Machine

| US$25,000.00-120,000.00 | 1 Piece (MOQ) |

Basic Info.

Model NO.

HT-PR02A

Certification

CE, ISO 9001:2008

Condition

New

Control

Automatic

Embossing Type

Full-Embossing

Embossing Roller

Steel Roller

Tissue Packaging

Bag

Function

Packaging

Tissue Type

Pull Out

Weight

12-13ton

Power

7.5kw Main Motor

Driving System

Timing Belt

Production Speed

80130m/Min

Transport Package

Wooden Cases

Specification

6570*3720*1525mm

Trademark

HUITONG

Origin

China

HS Code

8422400000

Production Capacity

120-150bag/Min

Product Description

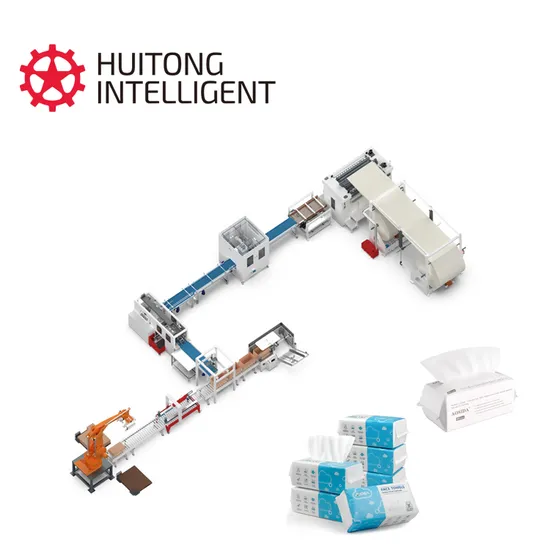

Automatic soft towel production lineProduct Description Revolutionary Facial Tissue Paper Production Line with Advanced Plastic Type Transfer System for Maximum Efficiency This State-of-the-Art Full Automatic Facial Tissue Production Line with Nylon Packing Type is composed of a comprehensive set of machines, including one Facial Tissue Machine (or Hand Towel Interfolding Machine) - expandable from 1 to 4 sets to match your capacity requirements - one Facial Tissue Log Saw Cutting Machine, one Full Automatic Facial Tissue Wrapping Machine, and one Automatic Facial Tissue Bundle Packing Machine, all designed to streamline your production process. Ready to embark on a lucrative venture in facial tissue or cotton towel production? Discover the essential machinery you need to succeed!

1. One Set of Highly Efficient Facial Tissue Folding Machine

2. One Set of Precision Facial Tissue Cutting Machine

3. One Set of Advanced Facial Tissue Packing Machine 4. One Set of Bundling Packing Machine for Ultimate Efficiency

Explore a variety of machine types, whether full auto or semi auto. We warmly invite you to consult with us and explore innovative production solutions tailored to your market's popular products.

Sophisticated Functions The maximum operational speed of the Fully Automated Facial Tissue Folding Machine, achieving an impressive rate of 100-130 m/min ♦ Intuitive operation and minimal maintenance, maximizing space efficiency with only one operator needed to transfer tissue logs post-operation ♦ Leverage our automatic cutting machine to dramatically boost production efficiency and ensure pristine tissues, free from human contamination ♦ Automatic shutdown feature when paper breaks, conserving resources by preventing undue waste Remarkable Features: 1. Seamless automatic counting and output for streamlined processing;

2. Versatile equipment offering 6-10 lines of varied models, providing customers with a broad range of choices. 3. Our 6-line facial tissue folding machine is perfectly aligned with current market demands, outperforming 2-4 line alternatives. 4. An independent valve control system for the knife groove ensures optimal adsorption and precise side-by-side folding. 5. State-of-the-art operation system featuring imported PLC and frequency conversion speed regulation for superior control.

Detailed Photos

Product Parameters

Key Technical Parameters:

1. Cutting-edge Tissues Fold Machine

| Machine model | HT-PR02A |

| Finished products unfolded size | 180*210mm±2mm |

| Folding products size | 90*(120-210)±2mm |

| Raw material width | 400-2800mm |

| Raw material diameter | 1100mm |

| Raw material core diameter | 76.2mm |

| Out put (8 hours) | 8000~10000Kg |

| Embossing unit | Steel to paper or steel to steel, Steel to steel edge embossing ,independent pneumatic regulation |

| Power | 7.5KW Main motor |

| 3.0KW(2set) Unwind motor | |

| Vacuum suction unit | 47KW Fan |

| Pneumatic system | 3 HP air compressor ,mini pressure 5kg/cm2PA |

| Driving system | Timing belt |

| Dimension | 8700X3500X7000mm |

| Weight | 12~13T |

2. Advanced Facial Tissue Auto Log Separator integrated into the machine

| No. | Item | Technical parameter |

| 1 | Sub-stack function | Adopts 4sets servo controlling, can achieve automatic separating |

| 2 | Sub-stack structure | Wall panel frame type |

| 3 | Sub-stack slide | All sub-stack slides adopt imported linear bearings, and adopt double-shaft structure to ensure the stability of each sub-stack part |

| 4 | Main sub-stack parts | All parts are aluminum alloy and processed by CNC machining center to ensure the accuracy of sub-stacking |

| 5 | Paper output baffle | All are processed by imported aluminum alloy to ensure the result of paper output |

| 6 | Sub-stack pneumatic part | Adopts AIRTAC pneumatic parts to ensure the accuracy of sub-stacking |

| 7 | Paper pieces tracking | Using high-precision encoder |

| 8 | Sub-stacking draws adjusting | Set on touch screen, can 100% accuratly adjust the draws(set based on even draws) |

| 9 | Set draws range | 2layers, 100-200draws; three layers, 60-150draws |

| 10 | Sub-stacking times | Max sub-stacking 10times/min |

| 11 | Controlling method | when machine common stop, it must finish the whole stack then can stop machine |

| 13 | Paper support part | Stainless steel is used to ensure the strength and rigidity of supporting semi-finished products at high speed |

| 14 | Sub-stacking servo motor power | 8.5KW |

| 15 | Compressed air pressure | ≥0.6MPa |

| 16 | Gas consumption | 1000L/shift |

| 17 | Air pressure | 24V |

Machinery Process diagram: Exchange of foreign friends:

CERTIFICATE:

>> 20t Virgin Pulp Traditional High Quality Paper Making Machine

>> Hot Selling High Frequency Textile Emboss Machine For Garment Embossing

>> Auto Grill stainless steel expanded metal Grille

>> Good Quality Injection Molding Machine for Plastic Flower Pot

>> Soft Black Slatted Metal Frame Foldable Multi XL Twin Size Bed for Kids

>> High Quality Home Bedding Set 3PCS Quilt Cover Jacquard Bedding Set Cotton Bed Sets

>> JIMBO wholesale coffre fort caja fuerte digital steel security drop cash deposit money storage depository safe

>> High-Quality K Serious Sk8 Variable Pitch Blow Molding Machine

>> Low Price Small Roll Paper Cutting Machine with Embossing

>> Conveyor Roller/Idler Making Machine of Automatic ISO Shaft Both Ends Flat Slot Milling Machine

>> Electronic Melt Flow Index tester MFR

>> 220V 380V 440V Wireless Remote Control Electric Material Lift Crane

>> Simple Interior LED Acrylic Warm Lights Use for Bedroom Hotel Living Room

>> Inflatable Rubber Airbag Launching Air Bags System Equipment for Ships

>> Semi automatic 5 gallon 18.9 L 20 L stretch blow moulding machine for pet bottle, 20 liter pet bottle blowing machine

>> Antenna Coaxial Cable Rg Series RG6 Rg11 Rg59 Rg58 RF Cable Bc CCS 75ohm 50ohm CCTV CATV Cable

>> Factory price waste plastic recycling machine with high quality

>> Automatic horizontal wafer biscuits food pouch pillow packing sealing machine

>> ASTM SUS316ti 304 316L Cold Rolled 06cr19ni9 Stainless Steel Coil 303 301 304n 06cr18ni11ti Strip Factory Price for Building Materials

>> tomato Sauce Processing Machine / High Quality Tomato Paste Production Line

>> The aluminum sliding skylight of the canopy system is windproof, waterproof, convenient and beautiful

>> High Frequency ERW Tube Mill Iron Ms Carbon Steel Pipe Making Machine Line Manufacturing Machinery Diameter 8-32mm Brazil

>> China Single Stepping Motor Drive Industrial Intelligent Lockstitch Sewing Machine Ss-610 with High Speed

>> Door to Door Logistics Service Top Shipping Companies Sea Cargo Rates From China to France Spain Italy Worldwide Shipping Agent

>> Flame Retardant Bird Eye Knitted Fabric/Modacrylic Viscose Conductive Fiber Fireproof Fabric

>> 12ga Bore Cleaner Rope Bore Brush Barrel Cleaner

>> Orange 3.6L Fuel Tank Aerobs Plough Power Tiller Walking Tractor

>> Excellent Performance Agricultural Machinery Full-Feed Mini Rice Combine Grain Compact Crawler Heavy Farm Harvester Machine

>> Multi-Layer Casual Canvas Bag Lunch Box Tote Book Bag

>> Taijia integrated rebar detector rebar locator pachometer Integrated Rebar Scanner