Lightweight Wall Panel Hollow Gypsum Board Production Line/Precast Concrete Wall Panel Machine

| US$25,000.00-300,000.00 | 1 Set (MOQ) |

Basic Info.

Model NO.

HFP512A

Power Source

Electric

Screw Design

Double-Screw

Certification

CE, ISO

Condition

New

Customized

Customized

Application

Drain Pipe

Material

Concrete

Weight

5000kg to 10000kgs

Warranty

One Year

Power

380V or 220V

Usage

Shopping Center, School, Hospital

Product Name

Lightweight Panel Hollow Gypsum Board Production L

Transport Package

Suitable for Road or Sea Way, Standard Packing.

Specification

3380*3200*2680mm

Trademark

Hongfa

Origin

Guangxi, China (Mainland)

HS Code

8474802000

Production Capacity

50, 000-1, 000, 000m2/Year

Packaging & Delivery

Package Size

10.00cm * 10.00cm * 10.00cm

Package Gross Weight

1.000kg

Product Description

Lightweight Panel Hollow Gypsum Board Production Line/Precast Lightweight Concrete Wall Panel MachineWall panel for concrete precast houses:

1.Full Automatic

2.Eco Saving and Advanced Technology

3.Low cost

4.ISO9001-2015

Products range:

Our wall panel prodcution line can manufacture kinds of wall panels :

Gypsum board, hollow gypsum board, wall panel with concrete, lightweight panel with hole, EPS wall panel

Introduction of Lightweight Panel Hollow Gypsum Board Production Line

1. Materials of Hongfa Brand EPS Wall Panel

1) Outside (side board)- Calcium silicate board or Cement fiberboard - Also can be without the side board.

2) Inside (core material)- Cement, Foam EPS, Fly Ash, Additives (Hydroxypropyl methyl cellulose) Or without EPS foam The fly ash can be replaceable by sand or other material

3) Gypsum, Glass fiber, water, ect.

2. Common Specifications of

Soundproofing foam Wall decorative panel machines for construction materials

EPS cement wall sandwich panel

L*W*T: 2440mm/3000mm/4000mm *610mm*50mm/60mm/75mm/90mm/100mm/120mm/150mm.

2270mm* 610mm*50mm/60mm/75mm/90mm/100mm/120mm/150mm/180mm/200mm/250mm.

Size can be customized by customer's requirement.

3. Applied range of Lightweight Panel Hollow Gypsum Board

For interior and exterior wall partition on steel or concrete structure building, new construction or renovations. It can be widely applied to wall materials of various high and low buildings such as bank, office building, hospital, school, hotel, shopping mall, amusement, old house reconstruction, residence and workshop.

4. Advantages of Lightweight Panel Hollow Gypsum Board Production Line

Light weight----Excellent sound insulation----- Heat Insulation

Waterproof Fire proof--------- Energy Efficient Environmental

Convenient construction-----High Intensity without deformation.

Suggested Staffing Table of Lightweight Panel Hollow Gypsum Board Production Line/Precast Lightweight Concrete Wall Panel Machine

| Position | Amount(Person) |

| Moulding/pouring | 1 |

| Demoulding&Packing | 1 |

| EPS Expander Operation/raw materials | 1 |

| Mixer Operation | 1 |

| Transportation | 1 |

| Total | 5 |

Hongfa Main Three types of Lightweight Panel Lightweight Panel Hollow Gypsum Board Production Line/Precast Lightweight Concrete Wall Panel Machine

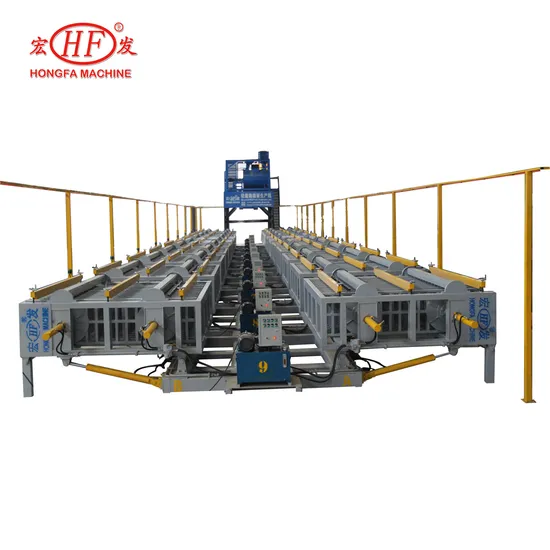

1. Horizontal wall panel production line :Horizontal type EPS wall panel making machine, Precast Concrete Lightweight Wall Panel Equipment Machine Production Line : high level of automatic operation,fewer workers required.

2. Vertical Manual panes de-molding production line

Manually vertical type partition wall board making machine, Precast Concrete Lightweight Wall Panel Equipment Machine Production Line : Manual operation,the highest output amount the three types, but requires more workers.

3. Vertical Automatic panels de-molding and stacking production line:

Automatic vertical type Precast Concrete Lightweight Wall Panel Equipment Machine Production Line : automatic operation,high output,fewer workers required.

The most advanced patent protected machine in China. Double capacity Higher working-efficiency.

Service

Guarantee for one year and after sale service for whole life.To offer free design,free technology support and free machine maintenance trainning.

Hongfa Group Established in 1990.

A leader developer& Manufacturer of Construction Material Machinery.

Main business Range & Products:

Lightweight Panel Production Line, AAC Block Production Line, Full Automatic Concrete Block Production Line, Artificial Quartz Plate Production Line, Concrete Pipe Machine, Concrete Tile Machine, Concrete pipe machine, Bidirectional Hydraulic Brick Maker, Mining Machinery, Concrete Batching plant, Stereo Parking Equipment, etc.

Hongfa Strengths

More than 30 years experience. 1500 employee (50+engineers)

2) Total 4 factories with 440,000M2 and annual sell above USD100 Million .

3) 10,000 customers and fulfillment to over 120 countries.

4) Continuous service and logistics system.

5) High quality products and competitive price.We hope we can cooperate with each other and establish a win-win business relationship.

Hongfa Machinery Group'Honor

1.One of Top Ten Influential Brands in China Brick &Tile Industry

2.National Enterprice Abiding By Contract & Keeping Good Faith

3.Quality and Credibility of the Dual-protectionb Demonstration Unit

4.High and New Tech Enterprise

5.Famous Trademark of China

6.Star Enterprise with China Patent

7.AAA Grade Credit Enterprise

8.Consumer Satisfaction Unit

9.One of Top 100 building Material Industry Brands of China

10.One of Top Ten Good Faith Units

11.Advanced Exporter in Guangxi Province

12.Advance Quality Management Unit

If you are interested in any product of our company, please feel free to contact me.

Any enquiry would get our professional and prompt reply!

Contact Information:

Foreign Trade Dept. : Emily Lee

Guangxi Hongfa Heavy Machinery Co., Ltd.

Mob.: +86 15177094840

Wesite: gxhongfa.en.made-in-china.com

>> Slst 1500-500t/1500t Fully Automatic Servo Vibration and Compression Integrated Block Machine

>> Dual-Motor Shredder Machine for Steel Scrap, Rubber, Tires & Timber Waste

>> Custom Housewares Ceramic Kitchenware Luxury Customized Gold Logo High Quality Ceramic Sugar Bowl for Wholesale

>> Expanded PTFE Sheet China Supplier Best Price

>> Large Size 361 363 for Human Consumption Chinese Sunflower Seeds for United Kingdom

>> European American High Quality Copper Golden Shadow Glass Brass Bronze Chandelier Decorative 6,8,10,15,24,40 Heads Arms LED Hanging Lights Fixtures Pendant Lamp

>> Wedding Transparent Acrylic Chair Mirror Big Round Back Chair Hotel Ballroom Wedding Hall Wedding Hotel Crystal Chair

>> 15-50kg Bulk Detergent Powder / Laundry Powder

>> Wire Cable 1t 2500lb Hand Winch for Boat Trailer Manual Winch

>> Natural Tooth Picks Good Quality Double Sidedbamboo Toothpicks

>> Heavy Cast Steel Machined Wind Turbine Hub Body Casting Parts

>> Wholesale Portable Universal Children′s Car Height Pad Safety Seats

>> Cavity aluminium frame black glass double sided lift and sliding door

>> 2024 New Reverse Series Pilot Sun Sunglasses

>> PLC Operated Precision Surface Grinding Machine Specification

>> Custom Logo Premium Luxury Cardboard Box Book Shape Flip Color Box Cardboard Box Gift Box Packaging Magnet Packaging for Dental Cleaners

>> Factory Directly Wholesale100% Handmade Autumn Scenery Landscape Oil Painting on Canvas

>> Asphalt Electrical Nuclear-free Density Gauge(EDG)

>> Plastic Profile Stile Cutting Saw High Quality UPVC Door and Window Cutting Machine

>> Modern New Design Slide Wooden Doors Hotel Apartment Bedroom Furniture Wardrobe

>> Pressure Vessel Glass Lined Chemical Reactor 5000L

>> Ticare Spinal Anesthesia Needle Suppliers 3.5 Inch Spinal Disposable Needle for Hospital Surgical

>> Custom Logo Machine Sewn Football for Competition and Training

>> Producing Steel Hot Rolling Mills From China with ISO Certificate

>> High quality aluminum standard expanded metal mesh for architecture facade decoration

>> Hard- Wearing Virgin UHMWPE Suction Box Cover

>> High-Precision Germany Manual Bench Lathe Machine New Brand Drehmaschine Medium Heavy Duty Horizontal Metal Work Core Motor

>> 2021 New Agricultural Multifunction Electric Cultivator

>> Paper Mill Pulp Making Process Stock 1m2 Inflow Fine Pressure Screen

>> 55kw Bx216 Wood Slab Chipper with Low Price for Sale