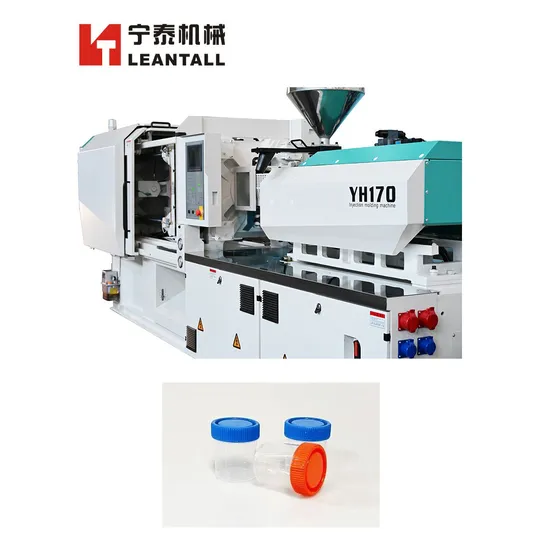

750 Ton Automatic Plastic Injection Molding Mould Machine for Efficient Manufacturing

Basic Info.

Model NO.

NT750

Type

Preform Injection

Structure

Horizontal

Plastic Type

Thermoplastic

Plasticizing Way

Plunger Type

Clamping Way

Hydraulic

Automation

Automatic

Computerized

Computerized

Certification

ISO9001:2008

Marketing Type

Hot Product

Core Component

Motor, PLC

Material

Stainless Steel

Applicable Industrial

Manufacturing Plant

Voltage

380V/50Hz 3p+N+E(Alterable)

Function

Plastic Parts Production

Mold

Can Be Customizable

Clamp Force

7500kN

Space Between Tie Bars

1020mm*970mm

Transport Package

at Seller′s Option

Specification

11m*2.4m*3.2m

Trademark

Leantall

Origin

China

Packaging & Delivery

Package Size

1100.00cm * 240.00cm * 320.00cm

Package Gross Weight

35000.000kg

Product Description

Product Parameters| Part | Name | Unit | NT750 | |||

| Injection Unit | SCREW DIAMETER | mm | 90 | 95 | 105 | 110 |

| SCREW L/D RATIO | L/D | 23 | 22 | 20 | 19 | |

| INJECTION STROKE | mm | 460 | 460 | 460 | 460 | |

| NJECTION SPEED | Mm/sec | 81 | 81 | 81 | 81 | |

| SHOT VOLUME(THEORETICAL) | CM3 | 2926 | 3260 | 3983 | 4371 | |

| INJECTION WEIGHT(PS) | g | 2662 | 2966 | 3624 | 3977 | |

| INJECTION PRESSURE | Mpa | 195 | 175 | 143 | 131 | |

| INJECTION RATE | cm³/sec | 515 | 574 | 701 | 769 | |

| SCREW SPEED | rpm | 109 | ||||

| Clamping Unit | CLAMP FORCE | Kn | 7500 | |||

| OPEN STROKE | mm | 1000 | ||||

| SPACE BETWEEN TIE BARS | mm×mm | 1020X970 | ||||

| MAX.MOULD HEIGHT | mm | 960 | ||||

| MIN.MOULD HEIGHT | mm | 400 | ||||

| EJECTOR STROKE | mm | 340 | ||||

| EJECTOR FORCE | Kn | 210 | ||||

| EJECTOR NUMBER | N | 17 | ||||

| Others | MAX.PUMP PRESSURE | Mpa | 16 | |||

| SEVRO DRIVE POWER | Kw | 45+37 | ||||

| HEATING POWER | Kw | 46 | ||||

| MACHINE DIMENSION(L*W*H) | m×m×m | 11*2.4*3.2 | ||||

| MACHINE WEIGHT(ESTIMATE) | T | 35 | ||||

Product Description

Packaging & Shipping

Company Profile

Our Advantages

Q: Are you manufacturer or trading company? A: We are manufacturer with decades experiences,located in Zhejiang province. Q: What is the product range? A: Focus on the manufacture and development of plastic injection molding machines and its auxiliary equipment such as cooling tower, chiller, etc. Q: Where is your main selling market? A: We have business domestic,USA,Russia,Indonesia,Egypt,Turkey ,Uzbekistan, Pakistan,etc. Q: Will you offer field installation and operator training at the buyer's factory? A: Yes,we will arrange our skilled engineers for filed installation and training. Q: What is the delivery time(equipment production time)? A: It will be ready around 50 days after getting mutual confirmation about the order details and prepayment. Q: Do you also have source for molds and spare parts? A: Yes,we can offer with the competitive quality and reasonable price. Customized as required. Q: What is the standard of package? A: Wooden case packing for the auxiliary equipment, bare packing for the plastic injection molding machine. Full container shipment is highly suggest.

>> Slst 1500-500t/1500t Fully Automatic Servo Vibration and Compression Integrated Block Machine

>> Dual-Motor Shredder Machine for Steel Scrap, Rubber, Tires & Timber Waste

>> Custom Housewares Ceramic Kitchenware Luxury Customized Gold Logo High Quality Ceramic Sugar Bowl for Wholesale

>> Expanded PTFE Sheet China Supplier Best Price

>> Large Size 361 363 for Human Consumption Chinese Sunflower Seeds for United Kingdom

>> European American High Quality Copper Golden Shadow Glass Brass Bronze Chandelier Decorative 6,8,10,15,24,40 Heads Arms LED Hanging Lights Fixtures Pendant Lamp

>> Wedding Transparent Acrylic Chair Mirror Big Round Back Chair Hotel Ballroom Wedding Hall Wedding Hotel Crystal Chair

>> 15-50kg Bulk Detergent Powder / Laundry Powder

>> Wire Cable 1t 2500lb Hand Winch for Boat Trailer Manual Winch

>> Natural Tooth Picks Good Quality Double Sidedbamboo Toothpicks

>> Hot Selling Design Brand Leather Crossbody Lady Travel Cosmetic Bag Fashion Shopping Women′s Tote Gift Handbag Replica Shoulder Bag

>> Double Horizontal Shaft Compulsory Mixer Concrete Mixer

>> Back Massage Cushion with Vibration Motors Heated Massage Chair Pad

>> Sightseeing Home Small Residential Panoramic Glass Elevator for Villa House

>> Full Automatic 6000b/H 500ml Plastic Water Bottles Manufacturing Machines

>> Chinese Fresh Potato Export Potato with Good Quality

>> 100-500kgs Per Hour Flour Mill Machine Maize Grinding Hammer Mill Maize Mill Corn Milling Machine Maize Flour Mill Corn Mill Corn Flour Mill Maize Flour Machine

>> KW1-M4500-015 SMT YAMAHA FEEDER CL24MM Feeder for pick and place machine

>> Hot Sales Customized Precision Metal Stamping of Auto/Home Appliance/Digital Product/Terminals

>> Lightweight Wall Panel Hollow Gypsum Board Production Line/Precast Concrete Wall Panel Machine

>> High Precision VHF350s Universal Fresadora Turret Milling Machine with Servo Motor

>> Double Cone Industrial Rotary Dry Powder Mixer Chemical Mixing Equipment

>> Farm/Garden Tractor Machinery Rotovator Tiller (1JMS-300)

>> Amazon hot sale OEM service men women sports weight lifting gym workout gloves Half Finger Exercise Weight Lifting Gloves

>> Automatic Food Packaging Liquid Juice Tomato Paste Detergent Hotel Bottle Hand Wash Liquid Soap Shower Gel Body Cream Lotion Shampoo Filling Machine Line

>> custom design 3 hole leather gymnastics hand grips workout gloves customized logo and color

>> Napkin Tissue Packing Machine 500 PCS Napkins Paper Bundling Machine

>> 65W Type-C Adaptor USB Laptop Power Adapter Charger for Lenovo Asus HP DELL

>> Wide Adaptability High Safety Performance Box Making Machine

>> Ygt4-12 CNC Hydraulic Steel Bar Straightening Cutting Machine with Favorable Discount