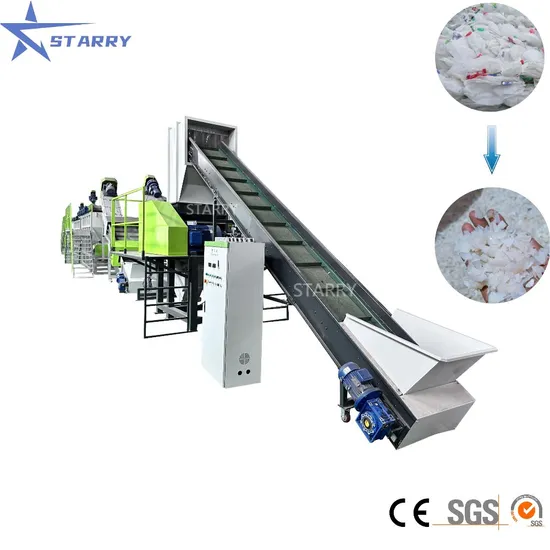

Better Price HDPE LDPE PP PE Pet Bottles Waste Plastic Recycling Crusher Machine Plastic Crushing Machine

| US$25,000.00-85,000.00 | 1 Piece (MOQ) |

Basic Info.

Model NO.

SPE300 SPE500 SPE1000

Material Processed

PE PP Film Bags, HDPE Bottles

Plastic Type

PE PP LDPE HDPE Pet

Screw

Multi-Screw

Automation

Automation

Computerized

Computerized

Certification

ISO9001:2008, CE

Name

Plastic Washing Recycling Machine

Final Film Size

30-50mm

Crusher Blade Material

SKD-11 or D2

Capacity

200-1000kg/H

Process Material

PP PE Bottle, Film and So on

Moisture Content Remain

1%

Final Product

Clean and Dry Scraps

Voltage

380V, 50Hz or Customized

Machine Material

Stainless Steel or Carbon Steel

Color

Grey, Green or Customized

Electrics

Siemens, ABB, Ormon

Transport Package

Seaworthy Packing for Plastic Recycling Machine

Specification

SPE300-1000 Plastic Recycling Machine

Trademark

STARRY

Origin

China

HS Code

84778000

Production Capacity

50 Lines/Year Plastic Recycling Machine

Packaging & Delivery

Package Size

350.00cm * 220.00cm * 220.00cm

Package Gross Weight

2500.000kg

Product Description

Product DescriptionThe PE/PP Plastic washing recycling line can treat various kinds of plastic soft and rigid materials, such as PE/LDPE/LLDPE film, PP woven bags, PP jumbo bags, waste agricultural film, industrial packing film, PE/HDPE/PP bottles, pipes, lumps and other injection waste materials, etc.

The waste dirty material go through crushing, friction washing, washing, dewatering, hot air drying process will turn to be clean flakes for pelletizing.

Product Parameters

| Item | Capacity(kg/h) | Water consumption(ton/h) | Installation power(kw) | Length(m) | Man power |

| SPE-300 | 300 | 1 | 120-150 | around 30m | 3 |

| SPE-500 | 500 | 2 | 200-250 | around 40m | 4 |

| SPE-1000 | 1000 | 3 | 300-350 | around 60m | 6 |

Detailed Photos

Plastic Crusher

Wet crushing with water, which can cool the blades and wash the plastic in advance Blades made of special material SKD-11 or D2, with high hardness Automatic by hydraulic system: easy operation to change blades or screen mesh

Rotor of Plastic Crusher

Friction Washer

Rotor and blades adopt wear resistant steel Rotor with balance treatment for stability Friction to clean the materials mechanically

Floating Washing Tank

All Thumb-wheel speed variable by inverter control Can use hot type washer to add chemical for washing All tank made of SUS 304 or even 316 if needed With sewage screw in the bottom of washer tank

Centrifugal Dewatering Machine

Continuously discharge the material from side and drainage from the bottom of this machine All the blade paddle is changeable which is easy for maintain service inthefuture. Main bearing brand: famous brand

Brush automatically cleans the surface of the screen mesh of the dewatering machine

Hot air Drying System

Pipeline build in stainless steel welded construction All parts touch raw materials are stainless steel Hot air drying system

Film Squeezer Dryer (For soft materials)

It can replace traditional centrifugal dryer to solve the drying problem The moisture of final scraps is less than 1%.

Electric Control Panel

Use SIEMENS PLC, ABB inverter, etc.

Packaging & Shipping

Company Profile

STARRY is a manufacturing company specializing in the production of plastic recycling and extrusion equipmeny, focusing on the research and development of plastic recycling and extrusion technology, providing plastic recycling, washing, regranulation, extrusion equipment and solutions. Our experienced engineers, over 25 years of knowledge and experience in plastic recycling and extrusion processing help us to contribute actively to the success of our customers by offering sustainable solutions that meet industry needs. STARRY focuses on plastic washing machines, plastic shredder, crusher, compaction and pelletizing systems, plastic extruders and control procedures that meet global standards. Our products have obtained CE/ISO/SGS/ certificate.

Certifications

FAQ

Q1. How do you guarantee the quality of your products?A1: STARRY guarantees all new products and parts to the first owner-operator to be free from defects in material and workmanship for a period of 60 months from B/L date, under normal use and service.Q2. How about the spare parts?A2: We could provide you reliable, fast and professional service through telephone, network and on-site at any time. Normally, we send our customer one set of spare parts together with the machines when we deliver the product.During the warranty, we provide new parts free of charge for you to replace, exclude the parts broken that caused by improper operation.In our spare parts department, you will get professional technical advice, as well as the relevant information regarding all products and services.Q3. About product qualityA3: STARRY is a prestigious plastic recycling and extrusion machinery manufacturer in China. Our customers have been enjoying a variety of advantages in particular in terms of the dedicated screw designed by our R&D team including good mixing, good dispersion, high productivity, and so on.Q4. After-sales serviceA4: 1.Send engineers to install, test the machines and offer technology guidance and worker training at customers' factory.2.Offer 18 months free maintenance and life long service. After the warranty period, spare parts will be provided at basic cost.3.Build customers database. All machines are traceable.4.Visit customers and make quality trace periodically and take customers' feedback into account during routine practices.5.Speed up service and spare parts supply.

>> Flexi Tank Liquid Transportation Flexitank in Flexi Bag 20FT Container

>> Galvanized or aluminum perforated sheet/perforated panel/perforated metal mesh

>> Mobile mini alluvial gold wash plant machine gold washing trommel screen

>> Aqualand 38feet 11.5m Rigid Inflatable Sport Leisure Fishing Speed Diving Motor Boat (RIB1150L)

>> Skytone Audio Dual 10 Inches Line Array Brx300 PRO Audio Line Array Speaker

>> Conventional Welded Wire Mesh Panel 50*50mm

>> 18 Cavity Automatic High Speed Cap Compression Molding Machine

>> Farm Tractor Trailed Tube Mf Disc Plough

>> Nizn Ferrite Core Fs25*5*21*12-1.5mm for Flat Wiring Harness and Ribbon Cable

>> Lk-630 2023 Upgrade Stepper Driven Higher Automation Wire Cutting Machine

>> 270/320/370/430L Rubber Banbury Powder Weighing System Chemical Mixer Equipment

>> Hot Selling Pretend Play Cutting Toy Birthday Cake Set Toy

>> High Quality ABS PC Over Mold Making Overmolding for Toolings Shell Mould

>> Sea Freight Shipping Agent From China to Bangladesh, Chittagong/ Dhaka

>> Tqc200 Angle Back Milling Machine for Angle Tower Fabrication

>> High Quality Front Fog Lamp headlight for Land Cruiser 2010

>> Industrial Cocoa Powder Processing Machine Cacao Bean Roasting Peeling Machinery

>> ODM OEM China Manufacturer Foldable Wire Storage Cage with Lid

>> Essential Oil Nitrogen-Containing Alkaloids Distillation Equipment

>> Shandong Xiangying Factory Price Machine Fabrication Maquina Fabricacion OSB Equipment

>> CNC Lathe Machine Tools Sdqcr/Sdqcl External Turning Tool Holder for Dcmt Carbide Inserts

>> Extrusion Blow Moulding Machine for 2layers IBC Tank

>> High-Performance Rk3568 4G Ai Edge Computer with RS232 Ports

>> Outdoor Reflector 100W 150W 200W 250W 300W 400W 500W 600W 800W 1000W LED Flood Light for High Mast Pole Soccer Stadium Sports Football Baseball Court Wharf

>> Cheap 18L 24L Medical Laboratory High Temperature Steam Vertical Sterilizer Portable Autoclave

>> Halva/Maamoul/Arabic bread Horizontal Flow Pack Wrapping Machine Packaging Machine

>> Dog Packaging Cheese Premade Bag Powder Filling Pouch Screw Vertical Automatic Water Juice Bag Fruit Pet Food Packing Machine

>> UPVC Plastic Extruder / Plastic Machine / High Speed PVC Cable Duct Extrusion Line PVC Cable Trunking Machine

>> Wholesale GPU Gtx 1660ti 3080 Gaming Card 6GB 1660s GPU Card

>> Face to Face Multi Frequency Rolling Code Remote Control Duplicator Yet2130