China Automatic Building Construction Material Gypsum Powder Making Machine

| US$150,000.00-800,000.00 | 1 Set (MOQ) |

Basic Info.

Model NO.

lvjoe-p2

Certification

ISO 9001:2008, CE

Control Type

CNC

Crushing Degree

Fine Grinding Machine

Automatic Grade

Automatic

Video Outgoing-Inspection

Provided

Machinery Test Report

Provided

Applicable Industries

Building Material Shops, Machinery Repair Shops, M

Raw Material

Gypsum Rock, Additives

Steel Structure

We Can Supply

Fuel

Oil, Gas, Coal

Annual Capacity

30000-500000 Tons

Key Selling Points

Energy Saving

Transport Package

Standard Package for Exportation

Specification

CE & SGS

Trademark

LVJOE BRAND

Origin

Hebei, China(Mainland)

Production Capacity

30000-500000 Tons

Product Description

Product DescriptionGypsum powder production line works based on the following process:

The Crusher will break the big-size gypsum ore into small 25mm pieces, and then the small pieces will be sent to the grinder, after grinding fine, the qualified raw gypsum powder will be sent to boiling furnace to calcine, and the unqualified part will be sent to grinder until it's qualified. After calcining, the qualified gypsum powder will be sent to spiral conveyor through hoist.

The spiral conveyor will send the calcined gypsum powder to silo for storage, and cool the powder during the process. The dust remover is on the top of silo, the unqualified part will be sent to grinder until it's qualified.

The stored gypsum will be sent to product storage through steel impeller feeder, spiral conveyor, hoist, and send the qualified gypsum powder to storage or workshop finally.

The top pulse bag-type dust remover will collect dust from crusher, particle silo. When the dust and dust gas get into the dust remover through inlet, the big-size dust particle will fall because the increasing size and decreasing wind speed. The small dust particle will be filtered by filter bag. The filtered gas will be got rid of by outlet.

Production Capacity:

10, 000tons/year ---- 200, 000tons/year

Quality of Final Product:

Conformity with Chinese National Standard GB/T 9776-1988

Raw Materials:

Content of CaSO4 2H2O in gypsum mine >80%.

The grade of mine and the crystal configuration will influence the quality of semi-hydrated gypsum.

Fuel for Production:

Natural Gas, Oil or Coal

Detailed Photos

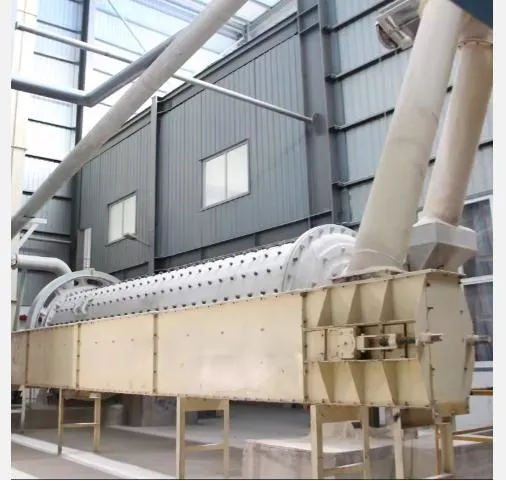

Name: crusher

Function: break big size gypsum rock into small size

Name: Raymond millFunction: grinding small size gypsum stone into raw gypsum powder

Name: Silo

Function: storage the final products

Name: Layout of the powder line

The basic process of making gypsum powder is: gypsum rock -- crusher -- raw material silo -- grinder -- calcinor -- silo-- packing machine

Our Advantages

Simple structure;it is not easy to damage Space-saving;intensive equipments The low cost of the energy High quality,the content of the hemi-hydrate is ideal,the physical property is stable. Packaging & Shipping

| Packaging Details | suitable for long distance transportationin containers or according to your requirement |

| Port | tianjin port |

Company Profile

Hebei Lvjoe Machinery Manufacturing Group Co., Ltd. was founded in 1998, which is a diversified development enterprise integrating R&D, design, production, international trade and engineering equipment. We are a strong unit with comprehensive strength in the national gypsum equipment industry.

We have the certificate of high-tech enterprise which is issued by the nation, the certificate of Gypsum Building Materials Equipment Research Center, the CE quality system certification which is issued by the European Union, the ISO9001 quality system certification. In 2011, the Gypsum Building Materials Equipment Research Center was established. It is a municipal-level civilized unit in Hebei Province, contract-honoring and trustworthy unit.

>> 2000W UPS 12V/24V/48 110V/220V DC Pure Sine Wave Power Inverter with Charger

>> UV Light Weathering Test Chamber

>> Plastic Dog Cat Pet Food Water Bowl Dish Mould

>> Pressure Screen Rotor Foil in Screen Basket for Pulp Paper Making Machine

>> Double Masts Vertical Lift of Gtwy2-8 "10m" Made in China

>> China Factory Small Micro Excavators 1 Ton Mini Excavators Crawler Excavator with Cheap Price for Sale

>> Precision Hydraulic Vertical Broaching Machine for High-Speed Production

>> Taijia ultrasonic flow meter china clamp on type ultrasonic flow meter tds-100f1 digital ultrasonic flowmeter

>> Custom New Design Modern High Gloss Slim Tall Uni Upper Corner Narrow White Shaker Carved Solid Dark Wood Rta Lacquer Modular/MDF/PVC/Melamine Kitchen Cabinet

>> China 350L Movable Cement Mixing Machine

>> Factory Price Bison Gasoline Engine 5HP Mini Poker Concrete Vibrator

>> Rotary Spindle 0-360 Degrees 5axis CNC Milling Machine Atc Wood Router 2040 2030 Foam CNC Machine for 3D Program Design EPS Foam Wood Metal

>> Cost-Effective Solutions in Metal Bending: Evaluating The Low Price Wf67K-M CNC Hydraulic Press Brake Bending Machine

>> World-Dawn 2 Wires Outdoor Christmas Decorating Round Shape LED Rope Light

>> french casement slim double sdpvc elegant hinge soundproof accessories cheap panoramic entry aluminium glass door

>> All-Weather Custom PVC Wristbands - Reliable for Amusement Parks and Training

>> China Low Price High Capacity Stone/Rock Hydraulic Cone Crusher

>> Electric Gas Heating Steam Jacketed Kettle Tilting Vacuum Double Jacket Kettle with Agitator Mixer / Jacketed Cooking Kettle Emulisifer Mixer

>> Soundproof curtain folding window and door terrace glazing aluminum windows and doors balcony large glass window for balcony

>> Easy Operate Excavator Stone Disc Saw Stone Cutting Machine

>> Photoelectric Smoke Detector Fire Alarm

>> Top Selling Fruit Heat Pump Dryer Mango Dehydrator Fish Drying Machine

>> Stamping Punch&Die Used for Simitch/Tox Press Fitting Machine

>> Gappro Anti-Scratch Instant Heat Self Healing Automotive No Yellowing Stretchable Self Adhesive Tph TPU Color Ppf Film for Car Wrap Vinyl

>> Chicken Sheep Animal Feed Pellet Production Line Machines and Feed Pelletizer

>> 9 Inch aluminum handle stainless steel folding novelty pocket knife

>> Brass cylinder valve oxygen-carbon dioxide nitrogen argon pressure relief valve

>> Decorative Glass Building Glass Color Painted Laminated Ceramic Fritted Glass

>> 4yzl-6 Corn Combine Harvesting Machine Farm Harvest Combine Harvester Multi-Function Machinery with 6rows for Rice,Wheat,Corn,Soybean,Sorghum Other Crop Grain.

>> China Pipe Grade Tinaye Brand PVC Resin Sg5