High Efficiency Wood Chips Hammer Mill Biomass Sawdust Hammer Mill

| US$41,500.00 | 1 Set (MOQ) |

Basic Info.

Model NO.

TFD75*130

Automatic Grade

Automatic

Controlling Mode

CNC

Energy Saving

Energy Saving

Certification

CE, ISO

Warranty

1 Year

Customized

Customized

Condition

New

Color

Multi Color

After-sales Service

Lifetime After-Sales

Power

132kw

Capacity

4-5tph

Weight

5.9t

Quantity of Hammer

96PCS

Material of Hammer

Manganese Steel

Material of Screener

Carbon Steel

Raw Materials

Agricutural&Waste Wood

Usage

Making Biomass Sawdust

Wearing Parts

Hammers+Sieve

Bearing

Hrb Brand

Diameter of Rotor

750mm

Transport Package

Container

Specification

3000*1950*2200mm

Trademark

TONY

Origin

China

HS Code

8479300000

Production Capacity

100sets/Month

Packaging & Delivery

Package Size

3100.00cm * 2050.00cm * 2300.00cm

Package Gross Weight

7000.000kg

Product Description

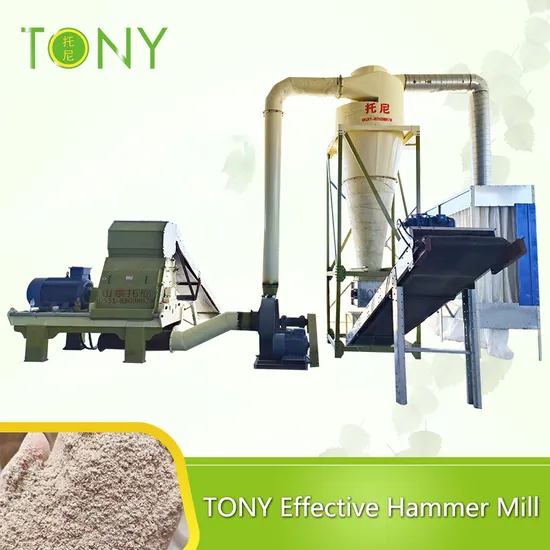

High Efficiency Wood Chips Hammer Mill Biomass Sawdust Hammer Mill with CE Certification Product DescriptionTFD series high-efficiency hammer mill is a pulverizer specially used for raw materials crushing in the biomass fuel production process. It has two series of single spindle and dual spindle, with features of high output and efficiency. It can crush wood chips, shavings, crop and plant crude fibers, roughage, etc

Advantages of our high efficiency hammer mill:

1. The shell adopts welded-steel plate construction, the main machine is embedded for seal, completely avoids dust spillover and maintains a clean work environment.

2. The motor and crusher are direct-connected driving with drum coupling and built-in rotors. Dead-zone free crushing and better uniform granularity.

3. The magnetic selector on the upper part can sort out the magnetic metal materials and reduce the machine's damage rate.

4. Forged hammers has symmetric homogeneous permutation, small vibration without blind angle, large crushing friction area. Wear-resisting material behind sieving slice has big wrapping angle. Hammer are independent designed with fasteners for easy assembly. The blades are enhanced for better wear-resistance and longer working life.

5. After balance calibration, rotors can work reversely.

6. The operating door has safety interlock equipment to make sure it can not be opened when the machine is running.

7. The blower's efficiency is maximized with faster pneumatic conveying and minimum wind resistance. Arc side door ensures easy observation and replacement of the sieve, without disturbing wind and flying dust.

Detailed Photos

Spare Parts of Hammer Mill

The sawdust making machine key spare parts such as hammers and screener are made by our CNC systems, through high technical heat treatment, standing out from other suppliers is that we could ensure the parts high precision and good quality.

Screener

The bottom diameter of screen is 6mm-12mm, thickness is greater than 4mm. Rotor Group

The motor and the hammers are directly connected by the coupling.

There is no dead angle during the crushing so the finished product is very fine.

The rotor has made the balance test and can work backward. Hammer

The corners of the hammers are welded with high hardness material like carbon tungsten alloy. The welding layer thickness is around 3mm. The lifetime is 7- 8 times by normal 65Mn overall quenching hammer.

Components of Grinding Process

| Item | Function |

| Belt Conveyer | To transport materials into hammer mill. |

| High Efficiency Hammer Mill | To crush the materials into 6-10mm sawdust |

| Blower | To help transport the sawdust into dryer |

| Cyclone | To discharge the materials and collect the dust |

| Air-lock | To prvent the outside air from entering inside |

| Bag Dust Collector | To collect the dust while in the production |

Product Parameters

Specifications of hammer mill

| Type | Model | Power(KW) | Capacity(T/H) | Hammer QTY(PC) | Size:L*W*H(MM) | Weight(T) |

| Single Shaft Hammer mill | TFD65*55 | 37-55 | 1-2 | 48 | 2000*1600*1700 | 2.5 |

| TFD65*75 | 55-75 | 2-3 | 72 | 2000*1800*1700 | 3.2 | |

| TFD75*100 | 90-110 | 3-5 | 90 | 2000*1800*1900 | 4.5 | |

| TFD75*130 | 132 | 4-5.5 | 96 | 3000*1950*2200 | 5.9 | |

| TFD75*130 | 160 | 5-6.5 | 120 | 3000*1970*2200 | 6.7 |

Raw Materials to Finished Products:

All kinds of wood, timber scraps, tree branches, wood chips, edge material, tree bark, bamboo skin and other material which can be crushed into sawdust.

Operating Principle:

Motor of Hammer crusher drives rotor to rotate in high speed in the crushing cavity. The materials are feeded into the machine through the upper feeding opening and are striked, impacted, sheared and grinded by high speed moving. Under the bottom of rotor, it is equipped with sieve plate. Among the crushed materials fractions that is less than mesh size are discharged through sieve plate, materials fractions that is bigger than mesh size are kept on the sieve plate to be striked and grinded by hammer and they are discharged out of machine finally. The main woriking parts of hammer crusher is the rotor with hammer. Rotor consists of main shaft, disc, pin roll and hammer.

Installation Instructions

Hammer Mill in Customer's Factory:

Certifications

Packaging & Shipping

Company Profile

CUSTOMER VISIT

TONY EXHIBITION

After Sales Service

CUSTOMIZED PELLET LINE:

Frequency Questions:

1.Q:Are you a manufacturer or agency?

A:We are a manufacturer with our own factory.

2.Q:Where is your factory located? How can I visit there?

A:Our factory is located in Zhangqiu City, Shandong Province, China.

You can fly to Jinan airport and then we will pick you up(40 minutes by car) .

All our clients are warmly welcome to visit us!

3.Q:How does your factory do regarding quality control?

A:"Quality is priority. We always attach great importance to quality

controlling from the very beginning to the very end. Our factory has

gained CE authentication.

>> Factory Outlet 4 Wheels Mixer Convenient and Labor-Saving Mobile Diesel Portable Mini Concrete Mixer

>> Wind Detector Wind Check Outdoor Hunting Wind Detector Wind Powder Wind Smoke

>> Traditional Design Stone Coated Zinc Steel Roofing Sheets for Milano Roof Tiles

>> Dehydrated Onion Powder and Red Onion Powder

>> High Compative 5t/Hr Tire Recycling Machine/Rubber Processing Machine

>> Fashion powder coating metal mesh cladding expanded metal grill grates

>> China Puxin Automatic Extrusion Plastic Blow Molding/Moulding Machine Production Line

>> Inner Bottom Milling Machine for Gas Cylinder

>> Automatic tailgate lift kit tailgate electric trunk boot sensor for toyota highlander

>> 0.3t-0.5t Small Red Palm Oil Press Oil Mill Palm Fruit Oil Expeller Oil Processing Machine in Malaysia Africa

>> Hand Cultivator Walking /Mini /Small/Farm/Agriculture/Diesel/Wheel/Farming Tractors

>> gift box double edge safety razor

>> 4X4 Isuzu Fvr 10 Cubic Meters 10 Ton Compactor Compressed Garbage Truck for Waste Colleaction

>> 4.5 inch customized multi-purpose wooden ice cream stick popsicle sticks for ice cream tongue

>> JOHNCOO Suspend Wobblers Pike Lures 130mm 21g Longcasting Fishing Hard Plastic Artificial Bait Tackle

>> Five Years Warranty 35000lm 250W Industrial IP65 Highbay UFO LED High Bay Light

>> Specialized CNC Machining Parts for Expert Metal Fabrication Solutions

>> Injection Moulds for Tongue Depressor

>> 20-1000L Mold Cleaning Agent Recycling Machine

>> Commercial Anti-Fatigue Non-Slip Hollow Drainage Playground/Pool/Kitchen Safety Entrance Flooring, Porous Rubber Floor Mat

>> Chilli Flakes Coarse Crusher From Shenzhou

>> Water Hyacinth Remover Aquatic Lettuce and Soldier Harvesting Equipment Boat

>> YFMA-920 laminating machine Paper Laminator

>> Plastic Portable Toilet Making Machine Rotomolding Machine

>> 26FT Small Boom Lift Self Propelled Vertical Mast Lift

>> 3G 850/1900MHz 3G USB Modem/3G USB Dongle

>> Psx-1500 Recycling Scrap Metal Shredder Line

>> Factory Price Automatic Raw Cashew Nut Peeling Machine

>> Hot Sale Heat Transfer Polyester Fabric Banner Cloth Flag 3X5FT

>> 2024 New Cartoon Pattern Packaging Children′s Happy Birthday Gift Shopping Bag