Tungsten Metal Powder 99.9% for Chemical Industry

| US$60.00-70.00 | 1,000 kg (MOQ) |

Basic Info.

Model NO.

Tungsten Metal Powder 99.9%

Purity

>99.95%

Alloy

Non-alloy

Shape

Powder

Type

Tungsten Powder

Product Name

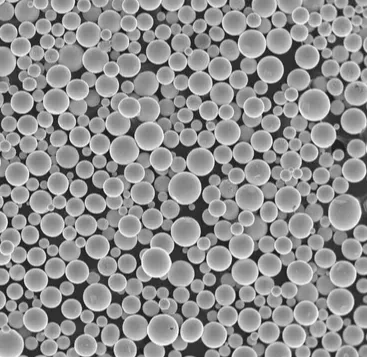

Spherical Tungsten Powder

Particle Size

40-149um

Sample

Available

Color

Silver and Grey

Feature

Corrosion Resistance

MOQ

1 Ton

Transport Package

Iron Drum

Specification

Spherical tungsten powder

Trademark

Yujiang

Origin

China

HS Code

8101100010

Production Capacity

1 Ton/Month

Product Description

Product DescriptionThe porous material prepared from spherical tungsten powder has the characteristic of uniform pore distribution. By controlling the production process, the air permeability of the product can be controlled, and the cathode of high power pulse microwave tube, electron barium tungsten cathode and gas filter material can also be prepared. Due to the good fluidity of spherical tungsten powder, the coating obtained in the field of thermal spraying is more uniform and compact, and the product has good wear resistance.

Packaging & Shipping

Specification

0-20μm, 15-45μm, 15-53μm, 53-105μm, 53-150μm, 105-250μm can be supplied according to customer requirements.

| Trace metallic impurities | |||||

| Element | Value(%wt) | MOA | Element | Value(%wt) | MOA |

| Cr | 0.0006 | ICP-MS | Co | 0.0005 | ICP-MS |

| As | 0.0005 | ICP-MS | Bi | 0.0001 | ICP-MS |

| Si | 0.0005 | ICP-MS | Mo | 0.0016 | ICP-MS |

| Al | 0.0005 | ICP-MS | Ca | 0.0005 | ICP-MS |

| Fe | 0.0010 | ICP-MS | V | 0.0005 | ICP-MS |

| Sb | 0.0005 | ICP-MS | Cd | 0.0001 | ICP-MS |

| Pb | 0.0001 | ICP-MS | Cu | 0.0001 | ICP-MS |

| Mg | 0.0005 | ICP-MS | Ti | 0.0005 | ICP-MS |

| Ni | 0.0005 | ICP-MS | P | 0.0005 | ICP-MS |

| Sn | 0.0001 | ICP-MS | K | 0.0005 | ICP-MS |

| Mn | 0.0005 | ICP-MS | Na | 0.0003 | ICP-MS |

| Nonmetallic impurities | |||||

| Element | Value(%) | MOA | Element | Value(%) | MOA |

| C | 0.0005 | LECO | S | 0.0008 | LECO |

| N | 0.0003 | LECO | O | 0.0100 | LECO |

Application

Used as the raw material of diamond drill bit and petroleum perforating charge for petroleum drilling, high temperature coating for combustion chamber and other wear-resistant and high temperature resistant parts.

Feature

| 1) Made by non-contact melting process; |

| 2) The powder has high sphericity, no hollow powder; narrow particle size distribution, good fluidity and strong density; |

| 3) The particle size range of Titanium Alloy Powders is 20-1000 μm; |

| 4) Effective control of powder particle size distribution; sphericity and oxygen consumption through optimized technology. |

| 5) Inert gas two steps treatment and compensation process can control the forming degree of EIGA producing atomizing alloy powder more efficiently. |

| 6) High purity spherical alloy powder with high sphericity, good fluidity and few non-metallic inclusions. |

Company Profile

Yujiang Chemical (Shandong) Co., Ltd. We are located in Shandong with convenient transportation access. We are a professional manufacturer and trader that is concerned with the research, development and production of chemical products. We committed to providing you with high-quality products and services. We always implement the concept of customer value creation, for customers tailored products,

to meet the needs of different customers, and continuously provide customers with solutions and technical problems.Further exploration and innovation, and excellence.Welcome and look forward to customers from all of the world to contact us for create a bright future with us together.

>> Auto engine water pumps BOMBA DE AGUA for CHEVROLET SPARK MATIZ 96666219

>> Custom Embossed Silk Screen Printing 28mm Sacmi Sake Carbonated Drink Till Sparking Juice Ropp Aluminum Water Screw Plastic Bottle Caps

>> Excavator Adapter 3G-8354/3G-8355/3G-8356

>> YFMA-800 Paperprocessingmachinery Carton Paper Box Laminating Machine for PVC Profile

>> Dustproof Hair Cover Ultrasonic Bouffant Cap Nurse Cap Making Machine

>> Whole body bio scan health analyz for help screening early disease equipment

>> Top Selling Customized Aluminium Extrusion Press Machine for Extruding Aluminum Profile

>> Chinese CNC Lathe Machine for Turning and Milling

>> Hot Sale Inflatable Boat Boat PVC Fishing Kayak for 2 Persons

>> landnovo Upgrade car LED headlight For 10-14 Mercedes w204 c260 c200 c300 headlamp

>> 57HS76-2004 NEMA 23 Electric Hybrid Stepper Motor 1.8 Degree 2 Phase Step Motor

>> China Factory Price Strong Load Bearing Automatic Hand Electric Powered Power Pallet Truck Jack in The Workshop

>> Tilling Machine Farm Mini Cultivator Price Garden Tiller

>> Badminton Squash Tennis Rackets Grip, Overgrip

>> CNC Hot Stamping Machine for Seamless Cylinder

>> C310/0020/STD ABB Redundant link module stock

>> Biodegradable and Compostable Scented Biodegradable HDPE Plastic Doggy Poop Bag Pet Bag Pet Waste Bag Food Tray Liner Nappy Bag Cat Liner Dog Waste Bag

>> Emersongear Wholesale Combat Clothing Outdoor Training Hunting Shirt Pants Military Tactical Uniform

>> F380 Cheap Radio Control Toys Kid′ S Remote Control R/C Helicopter

>> High Quality 3D Crystal Inside Engraving Machine

>> Car Bumper Full Set Wholesale Auto Part Body Kit For Audi A5 S5 Modified RS5 Front Rear Car Bumper Diffuser With Exhaust Pipe

>> Professional Grade Agricultural Mower for Efficient Grass Cutting,Professional Manufacturing Grass Mower,Lawn Mower,Reciprocating Mowerm,Flail Mower,Disc Mower

>> Dy 3phase 380V 50Hz Electric Electric Motor Wire Rope Small Home Use Lifting Winhes

>> Commercial Forestry Machinery with Reliable Gasoline Chainsaws for Logging

>> ASTM A193 B7 Heavy Hex Bolts

>> China Factory Polyester Roll of Non-Woven Fabric Spunlace Nonwoven for Wet Wipes

>> Number/Alphabet/Hebrew Brass Copper Flexible Heat Press Logo T Slot Tall Engraving Mold Letters Hot Foil Stamping Letter Stamps

>> Hand Push Single Row Corn Harvester Free Steering Corn Harvester

>> Mindray used BC5100 machine hematology analyzer mindray auto blood analyzer

>> Italy Type API Adaptor Discharge Valve