Three Layer Roofing Metal Sheet Roll Forming Making Machine

Basic Info.

Model NO.

Three Layer Roll Forming Machine

Tile Type

Colored Steel

Certification

CE, ISO

Condition

New

Customized

Customized

Usage

Roof, Wall, Floor

Transmission Method

Hydraulic Pressure

Suitable Material

Colored or Galvanized Steel Coil, Hrb60 or Equiva

Thickness Range

0.3-0.8 mm

Material Yield Stress

230~550 MPa

Roller Driven Type

Chain Transmission

Hydraulic System Pressure

12 MPa

Hydraulic Station Motor Power

Powert4 Kw

Main Motor Power

4~5.5kw

Total Power

7~8.5kw

Cutting

Automatically Stop and Cutting When It Comes to Th

Length of The Sheet

You Can Set The Length According to Your Need.

Coil Width Range

914, 1000, 1220 or 1250 mm.(According to Your Actu

Electric Power

380V, 50 Hz, 3 Phase(or According to Your Need)

Dimension

About 7.2*1.3*1.4m(L*W*H), as Per The Drawing

Roller Material

45# Steel with Chrome Treatment

Electric Components

Delixi or Chnt

Transport Package

Standard Export Package, Water-Proof Package

Specification

7800.00cm * 1500.00cm * 1400.00cm

Trademark

DX

Origin

China

HS Code

84552210

Production Capacity

100/1year

Product Description

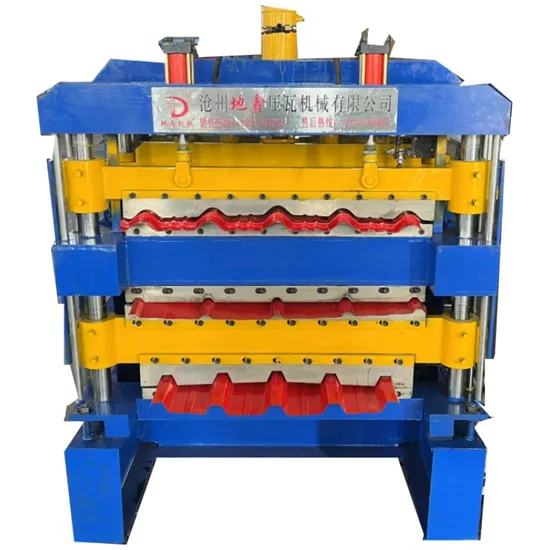

Different Color Metal Steel Products Roof Tile Cold Roll Forming Making MachineTriple-Layer Roof Shingles Roll Forming MachineProduct Description

Three layer roll forming machine, also called double deck roll forming machine. To meet the requirements for roll forming two different profiles in a limited plant area, the double layer roll forming machine is designed. The double deck forming machine is considered to be one of the most cost-effective roll forming equipment and has been widely used in many industrial plants and steel structures.Compared with the ordinary three layer forming machine, the three deck roll forming machine has great advantages. In order to produce different metal roofing sheets and metal wall panels, the machine is equipped with three layers of forming rollers. The palletizing system is adjustable up and down to accommodate the height of the two floors. The three layer roll forming machine can be used to produce corrugated steel sheets of two different shapes, such as three wall panels or roof panels, a deck panel, corrugated sheet, and so on. This machine can save a lot of work space and improve work efficiency. If you are interested in China roofing sheet machine, please feel free to contact us!

1.Our products can use galvanized steel sheet,colored armor plate or aluminum plate as the material plate.

2.Controlled by computer,PLC display,operationis easy,running is steady and reliable,endurable,maintence-free.

3.We can make and design what kinds of roll forming machine according to the request of customers.

4.Our products are widely used in various fields: industrial factory, civilian building, warehouse, easy steel building, manufacturing, construction and have features such as nice appearance and durable.

Our advantages:

High Quality

High Speed

Low Energy Consumption

Automatic & Easy Operate

Excellent Service

Panel Drawing: ( Send us your panel drawing, we can customize according to your requirement)

Product Pictures:

Applications: Product Parameters

Manual decoiler- Roll forming machine- PLC control- Hydraulic system - Post cut- Stacking

If you have specific requirements, that's no problem,We can meet all your needs.

| Suitable Material | Colored or galvanized steel coil, HRB60 or equivalent |

| Thickness Range | 0.3-0.8 mm |

| Material yield stress | 230~550 Mpa |

| Roller driven type | Chain transmission |

| Hydraulic system pressure | 12 Mpa |

| Hydraulic station motor power | 4 Kw |

| Main motor power | 4~5.5Kw |

| Total power | 7~8.5Kw |

| Coil Width Range | 914, 1000, 1220 or 1250 mm.(According to your actual drawing.) |

| Electric Power | 380V, 50 Hz, 3 phase(or according to your need) |

| Dimension | About 7.2*1.3*1.4m(L*W*H), as per the drawing |

| Cutting | Automatically stop and cutting when it comes to the set length. |

| Length of the Sheet | You can set the length according to your need. It is controlled by Delta PLC length accuracy: ±1mm. |

| Roller material | 45# steel with chrome treatment |

Certifications

other products

Customer's visit

Packaging & Shipping

After Sales Service

Advantage of the service:

1.Provide engineering drawing design service

2.Provide machine customization service

3.Remote video service

4.Engineer on-the-spot installation service

5.Help customers booking shipping service

6.Help customers purchase raw materials service

After-sales service:

1.Payment Term: 30% paid by T/T as down payment, the rest 70% after inspection by buyer in seller's factory while before delivery.

2.Delivery Time: We guarantee the equipment will be ready for shipment within 30 working days after receipt of deposit .

3.After sale Service: 24 hours technical support by email, WhatsApp, Wechat or phone call.We could send technician to your country to install machine if you need. The buyer need to pay for all the cost, including: visa, round trip tickets, accommodation, salary of USD 100~120 per day.

4.Warranty: One year guarantee for the whole machine and life-long maintenance.

FAQ

FAQ1. What are the main key points for selecting right machines?

A1: Whole structure,Roller Shaft,Roller Material,Motor&Pump,and Control system. As the new buyer, please kindly know that price not the final point.

Good quality is for long-term business cooperation.

Q2. Can you provide OEM service for roll forming machine?

A2: Yes, most of cold roll forming machine need to be customized as detailed request, because raw material , size , production usage, machine speed, then machine specification will be some different.

Q3. What's your standard trade terms ?

A2: We can provide the technical offer with FOB,CFR,CIF,Door to Door and so on. Please kindly tell the detailed port name for competitive ocean freight.

Q4. How about the quality control?

A4: Our company adopts 6S system to control every part with passed ISO9001:2000, CE,TUV/BV Certificate.

Q5. How about the after-sale service?

A5: We provide 18 months free warranty and free technical support for the whole life of any machine. During warranty period, if parts still broken, we can send the new ones freely.

Q6. If I am in Beijing,Shanghai or Guangzhou,how to visit your company?

A6: 1) Beiing South Statioin to Cangzhou West Station (by fast train 1 hour).

2) Shanghai Hongqiao to Cangzhou West (4.5 hours)

3) Guangzhou Airport to Tianjin ,then Tianjin to Cangzhou West

When you arrive our station, we will arrange to pick up you there!

This is one of our main products, hotselling used in Nigeria, and has been certificated by SGS, CE.

Hope further contact with you.

>> Vcauum Leak Tester ASTMD3078 Flexible Packaging Air Tightness Test Instrument

>> Commercial Gym Equipment for 2" Cast Iron Weight Plates with 7FT Barbell Set

>> Aluminum Composite Panel PE for Ads Printing Board Signature Decorative Building Materials

>> Custom Logo Self Adhesive Screen Printing Kraft Paper E-commerce Shipping Box Zipper Tear Corrugated Paper Packing Box

>> High Performance Nylon Resins Polyamide PA66 A3eg5 Virgin 25%

>> Injection Home Use Riha Mold Molding Products Mould Plastic Gear Wheel Hot

>> T3 series water meter for Liquids Quantitative Control ultrasonic water flow meter

>> High Quality Car Bumper Standard Edition Front Bumper For 17-20 Benz E Class W213 Modified E63S Amg Grille Flog Lamp Grill Kits

>> Graphite Tape for Spiral Wound Gasket Filler Flexible Graphite Foil Graphite Paper

>> Pouch Hole Non-Woven Gift Shopping Carrier Bags with Printed

>> China-Originated Nylon Raw Material Jhs J2700 Granular Polyamide 6 Resin for Strong Engineer Manufacturing

>> Straight Welded Carbon Profiled Square Steel Pipe (10# 20# 45# Q195 Q215 Q235 Q345)

>> China Factory Sale High Quality 818m/H/Ah Surface Grinder Automatic Surface Grinding Machine

>> Body Kits for Porsche Cayenne 958 Body Kits 2011-2014 body kits for Cayenne 958 MY Style

>> 6in1 IP65 150W Stage Effect Lighting DMX Disco Light LED PAR for DJ Party Bar KTV Nightclubs

>> Manufacturer Wholesale Recycled Plastic Raw Material Polyvinyl Chloride PVC Resin Sg3/Sg5/Sg8/S-65D/K67/K57//K70/S1000 White Powder Price with CAS 9002-86-2

>> USG6385E Multi-Port 10 Gigabit Enterprise-Level Ai Hardware Firewall

>> Outdoor Weeding Household Sponge Stretch Knee Pad

>> ABB PC D230 PC D231 B supply DCS system AC 800PEC controller

>> High-Speed 1/4 Fold Napkin Tissue Packing Machine for Efficient Production

>> LED Wall Washer for Energy-Efficient LED Lighting Solutions

>> 15kHz 2600W ultrasonic plastics welding machine generator system for auto production line

>> Outdoor Stadium High Mast Sports Football Field Pitch Golf Baseball Tunnel Tennis Court Light 100W 150W 200W 300W 400W 500W 600W 800W 1000W LED Flood Lighting

>> High Precision Slant Bed CNC Lathe Machine with Bar Feeder (BL-S32/32T)

>> stainless steel cooking pot electric cooking pot jam cooking pot

>> Promotion Price Poultry Animal Ring Die Livestock Pig Feed Pellet Mill for Making Cattle, Chicken, Broiler, Rooster, Fodder Pellet

>> High-Quality Safety Durability Waste Metal Shredder for Lithium Ion Battery Recycling Plant

>> Feed Grade Additive L-Lysine High Content 98.5% White Crystal Powder L-Lysine Hydrochloride

>> 60m Detection Distance 0-90, 000ppm. M Uav Laser Methane Sensor for Drone

>> Special Design Shredder for Plastic Film/Tire/Rubber/PVC Pipe/Spring Sofa/Foam/Kitchen Waste/Municipal Waste/Animal Bone/PCB/Tire