Semi Automatic Pet Bottle Blowing Molding Machine / Bottle Blower

| US$5,000.00-5,300.00 | 1 Set (MOQ) |

Basic Info.

Model NO.

BM-8Y

Making Method of Parison

Stretch Blow

Automation

Non-Automatic

Computerized

Computerized

Certification

CE, ISO9001:2008, TUV

Suitable Preform Material

Pet, PP Preforms

Suitable Bottle Size

100ml-2000ml

Capacity

1200-1500PCS/H

Max. Mold Plate Distance

390*345mm

Max. Mold Thickess

Adjustable

Clamping Force

100kn

Power

16kw

Blower Size

1460*580*1800mm

Oven Size

1350*550*1150mm

Name

Semi Automatic Pet Bottle Blowing Molding Machine

Transport Package

Wooden Case

Specification

one oven and two blowers

Trademark

BORUN

Origin

China

HS Code

8477300000

Production Capacity

1200-1500PCS/Hour

Product Description

Semi Automatic PET Bottle Blowing Molding Machine / Bottle BlowerBM-8Y semi automatic PET bottle blow molding machine is suitable for producing PET plastic containers and bottles from 100-2000ml. It is widely used to produce the carbonated bottle, mineral water,carbonated drink bottle, pesticide bottle oil bottle cosmetics,wide-mouth bottle etc.

Equipment list:

| NO. | NAME | MODEL | QTY |

| 1 | Semi-automatic PET bottle blow molding machine (one oven+two blowers) | BM-8Y | 1set |

| 2 | Blowing mold | 100ml-2L | 1set |

| 3 | HP Air Compressor | 1.2m3/min 30Kg | 1set |

| 4 | Air dryer | 2.0 m3/min 30Kg | 1set |

| 5 | Air filter | 2.0m3/min 30kg | 2sets |

| 6 | Water chiller | 3HP | 1pc |

*Spare parts List :

Seal cushion(10pcs);Lamps(5pcs);Fuse(3pcs);Switch(1pcs);breaker(1pcs);Silicon controlled (1pcs)

pressure adjust (1pc)

Features:

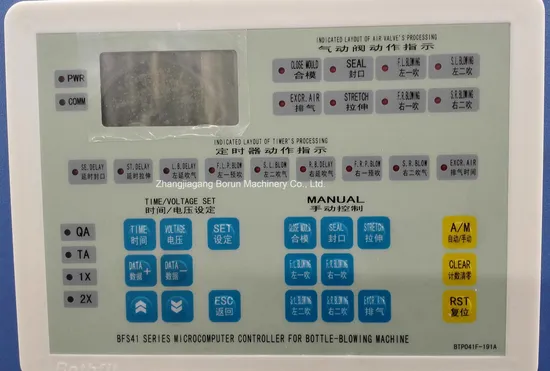

· Adopting double crank to adjust mould ,heavy locking mould, stable and fast ,Adopt infrared oven to heat the perform ,the perform rotated and heated equally.

· The air system has been divided into two parts: pneumatic action part and bottle blow part to meet the different requirements for the action and blow .It can provide sufficient and steady high pressure for blowing large irregular shaped bottles.

· The machine is also equipped with muffler and oiling system to lubricate the mechanical part of the machine.

· The machine can be operated in the step-by-step mode and the semi-auto mode.

· The machine is small with low investment, easy and safe to operate.

Technical Parameter of blow molding machine:

| Model | BM-8Y | |

| Container | Product material | PET |

| Volume | 0.1L-2L | |

| Theoretical output | 1200-1500PCS/H | |

| Max. product diameter | 180mm | |

| Max. product height | 300mm | |

| Molding | Max. mold plate Dimension(L x W) | 390x345mm |

| Die force | 100KN | |

| Die stroke | 270 | |

| Max. pulling stroke | 400 | |

| Blow pressure | 1.2-2.8Mpa | |

| Operation pressure | 0.8Mpa | |

| Machine size and weight | Machine size(LxWxH)(m) | 1.46x0.58x1.8m |

| Machine weight(KG) | 650KG | |

| Heater (L x W x H) | 1.35x0.55x1.15m | |

| Heater weight | 350Kg | |

| Power | 17.5kw | |

HP air compressor:

| Air compressor | Unit | 1.2M3/min 30KG |

| Volume | M3 | 1.2 |

| Pressure | Kg | 30 |

| Speed | r/min | 850 |

| Power | KW | 15 |

| Overall Dimension | mm | 2000*1100*1600 |

| Weight | kg | 620 |

Air Filter:

| Refining-Filter | Unit | 1.0M3/30Kg |

| Flow Capacity | M3/Min | 1 |

| Max. work pressure | Mpa | 3.0 |

| Inlet Temp. | ºC | ≤50 |

| Cold Medium | mm | 650*250*250 |

| Weight | Kg | 15 |

Air dryer:

| Refrigeration Air Dryer | Unit | 2.0M3/min 3.0Mpa |

| Flow capacity | Nm3/min | 2.0 |

| W.P | Mpa | 3.0 |

| Inlet Temp. | ºC | ≤80 |

| Dew point | ºC | 23 |

| Ambient Temp. | ºC | ≤38 |

| Power supply | V/HZ | 220/50 |

| Compressor power | Kw | 0.75 |

| Cold Medium | mm | 1050×650×1100 |

| Weight | Kg | 120 |

water chiller:

| Model | 03WCI | |

| 4.4/38ºC Cooling capacity(Kcal/h) | 7188 | |

| Compressor | All-closed vorticity | |

| Compressor power (KW) | 2.5 | |

| Refrigerant | R22 | |

| Chilled water pump power(KW) | 0.75 | |

| 10ºC Max. flow rate of chilled water(L/min) | 55 | |

| Flow water inlet and outlet pipe | 1'' | |

| Condensing water rate L/min | ≥36 | |

| Chilled water inlet and outlet pipe | 1'' | |

| Exterior dimension | Length(mm) | 1000 |

| Width(mm) | 600 | |

| Height(mm) | 1180 | |

| Water tank capacity | L | 50 |

| Weight | Kg | 150 |

>> CNC Rotary Knife Fabric Sample Garment Digital Cutting Plotter Price Cheap Automatic Roller Blinds Zebra Blind Fabric Cutting Table

>> Automatic Disposable Nonwoven Bed Sheets Folding Making Machine

>> Industrial Liquid Nitrogen Making Plant

>> Factory Direct Sale 16X16cm Italian Imitation Gold Leaf Foil Sheets 10000 Sheets Gold Leaf for Furniture Deco

>> Wholesale Cat Tree of Big Pet Furniture with Pet Products Pet Toyspet Supplypet Plush Toyfor Pet Supplier

>> Compact Hole Punching Machine Shoe and Belt Making

>> 4" Cold Air Intake System Heat Shield for Gmc Chevy V8 4.8L 5.3L 6.0L Sierra 1500 2500 3500 Air Filter

>> Four-Button Wireless Remote Control Kit with Signal Receiver for Truck Tail Lift

>> For BMW 3 Series G20G28 Carbon Fiber Rearview Mirror Shell

>> Skb041-6 Saikang Wholesale Multifunction Foldable Operation Connecting Medical Patient Stretcher Trolley

>> Foldable Stand for Mag-safe Charger Holder,Adjustable Desktop charging mount bracket Phone holder for iPh 12 wireless charger

>> OEM Power coating Aluminium Expanded Metal Mesh Filter Mesh in China

>> Automatic Fish Feed Machine Supporting Industrial Fish Feed Machine Applications

>> Electric Repeating Toy Gun Soft Large-Capacity Bullet Magazine EVA Soft Bullets Toy Gun for Boys (10503717)

>> Premium Tower Crane Repair Casting Parts Available for Purchase

>> 2024 Hot-Sale Manufacturer/Supplier ISO17357 Ship-to-Ship 50kpa/80kpa Floating/Pneumatic/Yokohama Rubber Fender Price for Sale/Boat/Ship/Vessel/Dock/Marine/Sts

>> 100kw Natural /Biogas/Biomass Gas Generator Price

>> 100% Sticked Composite Fiberglass Battery Separator for Lead-Acid Battery 136*148*1.6mm 8 Lines

>> MDF / HDF / OSB / Particle Board / Plywood Board Sanding Polishing Machine Sander Spare Part Polishing Drum Roller

>> Dry Roasted Peanut Peeler Peanut Red Skin Peeling Machine

>> Dongyou Good Temperature Control System PU Foaming Machine Dy-Hgc7202

>> Factory Direct Crusher Complete Set of Equipment for All Kinds of Raw Materials

>> Supplier Natural Skin Whitening Agent Apple Extract Phloretin Powder CAS 60-82-2

>> Taijia TUF-2000B+TM-1 Digital Ultrasonic Flow Meters Flowmeter DN50-700mm 1.97-27.56in with Medium Clamp-on Sensor TM-1

>> Body Fat Tester Mini Handhold Personal Skin-Fold Measure Tool Fitness Fat Caliper for Loss Weight

>> Car Door Panel Good Price Auto Body Parts SYLPHY G11 Almera Classic Car Front Door Car Left Front Door

>> 200 model 7.5kw 15HP Diesel Electric PTO Biofuel wood rice husk sawdust pellet making line for animal feed

>> CNC Aluminum Window Saw with Good Quality

>> Titanium Dioxide Toner Industrial Vibrating Screening Separator Equipment

>> Powerful 5 Axis CNC Machine, Innovative CNC Machining Center (V8/V11)