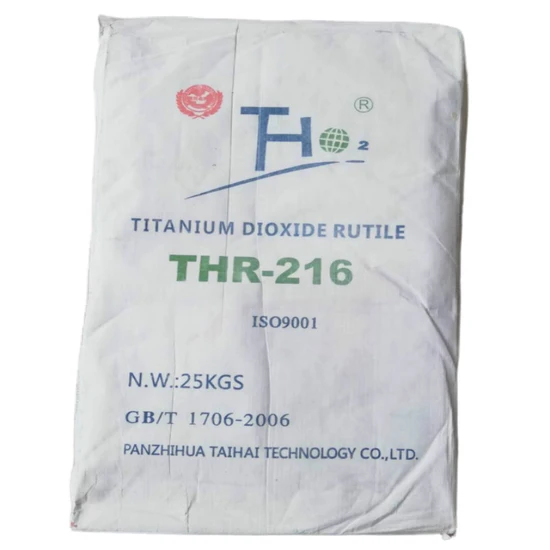

High-Quality Titanium Dioxide Rutile for Paints and Coatings

Basic Info.

Model NO.

THR-216, 218

EINECS

236-675-5

Classification

Titanium Dioxide

Grade Standard

Industrial Grade

Kind

No Salt Oxide

Quality

First Class

Grade

Rutile

Application

Plastic, Paints, Coating

Coating or Not

Coat

Funcation

White Pigment

Transport Package

25kg

Specification

99.9

Trademark

WSD

Origin

China

HS Code

28230000

Production Capacity

5000mt

Product Description

Product Description Titanium Dioxide RutileCrafted with precision, our universal titanium dioxide pigment, derived from the advanced sulfuric acid process, represents the pinnacle of innovation. Harnessing cutting-edge particle size control and unique coating technology, it is adorned with a silicon and aluminum inorganic coating, complemented by a special organic treatment. This powerhouse of a pigment offers remarkable optical properties, superior pigment performance, brilliant whiteness, and a stunning high gloss. Experience unmatched covering power, robust achromatic strength, and unparalleled weather and pulverization resistance. With low oil absorption, exceptional wettability, and effortless dispersion across various systems, it is the definitive choice for your needs. Product Parameters

Technical Index

| Item | Index |

| Titanium dioxide content,% | 93.5min |

| Matter soluble in water % | 0.5max |

| Organic treatment | yes |

| Rutile content,% | 97.5min |

| Oil Absorption | 16-20 |

| Color CIEL | 97.5min |

| Residue on sieve 45µm % | 0.1max |

| PH of aqueous suspension | 6.5-8.5 |

| norganic treatment: | silicon , Aluminum |

Application:

THR-218 is expertly designed for excellence in coatings and inks.

THR-216 is optimized for superior performance in paints and coatings.

THR-6666 is tailored for exceptional results in rubber and plastics.

Packaging & Shipping Package:

Presented in 25kg bags, configure your shipping to 22 tons per 20-foot container with pallets or 25 tons without pallets, ensuring flexibility and efficiency.

After Sales Service

Our Advantages 1. A comprehensive range of products to fulfill every customer requirement.

Beyond manufacturing a variety of PVC additives and PVC chemicals, we foster strategic alliances with other Polymer Additives factories. This synergy allows us to adhere to stringent product standards and customize to end-user specifications, ultimately delivering a holistic one-stop solution for your PVC chemical needs.

2. A dedicated testing team guarantees unparalleled quality. Our specialized product development and testing team ensures each PVC chemical we supply meets the rigorous technical demands of the PVC industry, ensuring your utmost satisfaction before any product dispatch.

3. Swift and Adaptive Shipment Solutions. Our expansive warehousing capabilities and numerous partner factories empower us to execute shipments swiftly and adaptably, catering to the unique requirements of our PVC plastics clientele with delivery times spanning 7-10 days.

4. Minimized Investment, Maximized Returns. In addition to offering a diverse array of plastic additives, we extend PVC plastics production formula support to our customers. This initiative aids in reducing costs across purchasing, time, capital, and risk, fostering a mutually beneficial partnership that maximizes returns for both parties.

5. Flexible Payment Solutions. Committed to easing payment challenges and mitigating costs, we offer various banking channels in China, Singapore, and Hong Kong. Available methods include TT, LC, and DP, among others, tailored to suit your payment preferences.

6. Specialized Technical Service Team. Most crucially, our expert technical service team delivers professional guidance and support, backed by extensive experience in the PVC & rubber sector. From PVC pipe and fitting to profile, board, sheet, soles, and more, we guide you through raw material selection, formulation, application, and production optimization. We stand ready, dedicated to serving you with excellence.

>> Food Grade Conveyor System for Beverage Industry Applications

>> Ama Vr Multiplayer 9d Cinema Rotation Roller Coaster 360 Degree Reality Virtual Simulator

>> Taijia ZD310 Concrete Rebar Scanner Ferro Scanner Metal Detector Ferro Scan Rebar Locator

>> Wholesale Kd-Zg100 Automatic One Time Paper Cup Lid Making Machine Price

>> New Condition CNC Hydraulic Press Brake Carbon Steel Processing High Productivity with Synchronized End Forming Services

>> Lathe for Turning Wood Automatic CNC Machine CNC Wood Turning Lathe Cutter Wood Lathe

>> Orange juice press, manual juicer, extruder, multi-function lemon juice press juicer

>> A62 Multifunction 2 Pins Wall Socket with Indicator Lighter

>> Jy-Scz2+ Mini P Electrophoresis Machine Gel Electrophoresis Equipment for Hemoglobin Detecting Vertical Electrophoresis Tank, Hospital Equipment, SDS-Page

>> Dz-600/2sb Double Chamber Forming Vacuum Packaging Machine For Food

>> Precision Customized Non-Standard Parts Turning Milling Drilling Tapping Anodizing Valves Joints

>> Gamemax Dual Glass Computer Gaming Case, Full Tower Big Space, Support Full Range High GPU Rtx Cards

>> PP-S2 Motorized Aluminum Horizontal Retractable Awning Canopy for Restaurant

>> 1400kN Plastic Injection Molding Machine for Small Items

>> The Piston Rod Chromium Plating Qpq Treatment Gas Spring

>> Small Wood Pallent Handling Crusher Machine

>> Metal Lathe Big Turning Manual Lathe Machine Cak6140 Cak6150 Cak6160 Cak6166 Cak6180

>> in Stock Lifting Height 0.8-2.4m Grain Silo Hydraulic Jacking System

>> Advance and Stable Performance Hammer Crusher for Brittle Materials with Copressive Strenght Lesst Than 150MPa.

>> Fashion Hoodie with Beach and Fat Fish Pattern

>> Wholesale Bench High Precision Lathe M Series Turret Milling Machine

>> QC12K CNC Plate Cutting Machine Hydraulic Shearing Machine

>> Copier Toner Cartridge for Xer 1810 2010 2220 2240 2011 2320 2520 2110 Fujixer Toner

>> Manufacture 100kg to 1000kg Mini Wire Rope Electric Hoist Winch PA100 100 to 1000kg Mini Electric Hoist Price

>> Treatment of seawater desalination reverse osmosis system 4040 frp ro membrane shell

>> Examination Gloves Production Machine Latex Glove Making Glove Dipping Machine

>> Roadside Slopes Pavement Truck Wheel Colorful Grounding Mat Car Parking

>> SINOBI Color Gradient Dial Watch Lady Mesh Band Wristwatch Diamond Decoration Bezel Girls Watch OEM Watches

>> Manufacture Reliable Supplier 24000 BTU 3P Air Conditioner 2 Ton

>> 47-051762-004 Connecting Link (SP TNG assembly) for Brunswick Bowling Machine