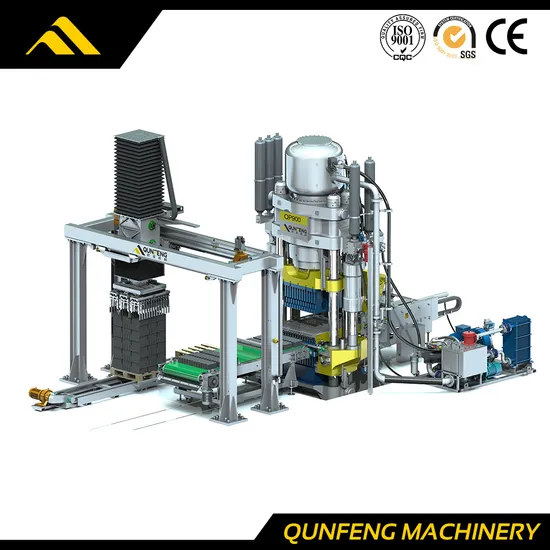

Static Pressing PLC, Pressure Vessel, Motor Construction Machinery Hydraulic Forming Machine

| US$320,000.00-600,000.00 | 1 Set (MOQ) |

Basic Info.

Model NO.

QP900

Type

Hollow Block Making Machine,

Max. Pressure of Main Cylinder

32MPa

Method

Hydraulic Pressure

Automatic

Yes

Key Selling Points

Static Pressing

Brick Raw Material

Concrete

Core Components

PLC, Pressure Vessel, Motor

Machinery Test Report

Not Available

Processing

Brick Molding Machine

Warranty of Core Components

1 Year

Local Service Location

Viet Nam, India, Kenya

Production Capacity (Pieces/8 Hours)

9360 PCS./Hour

Marketing Type

Hot Product 2020

Showroom Location

None

Video Outgoing-Inspection

Not Available

Trademark

Qunfeng

Origin

Fujian, China

Production Capacity

100 Set/Sets Per Year

Product Description

Product DescriptionQP900 Automatic Static Pressing Machine for Making Solid-Waste Brick

This model adopts the board-free fully automatic press forming, no pollution and low noise.The constant power variable pump is adopted to provide the power source for the system and the pump output energy is automatically adjusted according to the actual working conditions. Moreover, a more optimized hydraulic control system is equipped to make the whole machine more energy-saving and efficient.

Main Technical Features:

1.Hydraulic forming, save energy and improve efficiency:

This model adopts the board-free fully automatic press forming, no pollution and low noise.The constant power variable pump is adopted to provide the power source for the system and the pump output energy is automatically adjusted according to the actual working conditions. Moreover, a more optimized hydraulic control system is equipped to make the whole machine more energy-saving and efficient.

2.Bidirectional press and high yield:

The block forming is realized by the bidirectional press with the main cylinder presses first and the demoulding cyclinder presses subsequently, which can ensure the high density and high quality of blocks.

3.Rotary cuber:

The clamping componets of the cuber can realize the overall rotation, so the blocks can be stacked layer by layer crossly with 90 degree to enhance the stability of the cuber.

4.Advanced and reliable control system:

It adopts servo proportional valve, linear displacement sensor , closed loop control technology of servo motor and optimized electronic control system to achieve strong anti-interference ability, fast response and precise control of pressure and position.

5.Wide adaptability:

With a variety of optional batching methods and large-stroke demoulding cylinder, this model can produce blocks of different specifications with various raw material.

Technical data

| Max.Pressure | 9000 KN |

| Max. Demoulding Force | 2000 KN |

| Max. Height Of Mould Frame | 350 mm |

| Pressurization Times | 2-3 c/m |

| Max. Pressure Of Main Cylinder | 32 MPa |

| Cycle Time | 15-17s |

| Power | 102.1 Kw |

| The Space Of Left&Right Column | 1300 mm |

| The Width Of Working Table | 950 mm |

| Max. Work Distance Of Main Cylinder | 590 mm |

| Compressed Air Consumption | 4.5 m3/h 6bar |

| Cooling Water Consumption | 40 m3/h 30 3bar |

| Hydraulic Oil Capacity | 1100 L |

| Total Weight | 40 T |

| Production Capacity | Solid Brick (240×53×115mm) 39 Pcs. |

| Perforated Brick (240×115×90mm) 18 Pcs. | |

| Hollow Block(390×190×190mm) 8 Pcs. |

Customer Case

About us

Sales Team

Main Products

Application Case

CERTIFICATE

Packaging & Transportation

>> 72%Nylon 18%Cotton10%Spandex Fabric High Elastic Fabric for Activewear Sportswear Sport Top/Pants/Tank

>> T3 220V 60HZ Cooling Only 60000Btu Air Conditioner Floor Standing

>> SPA Disposable Bed Sheet Cover for Travel with Elastic Band

>> Car Body Part X3 G08 G01 Front Bumper Guard Plate Body Mudguard 51757394744

>> Cem Microwave Digestion System Sample Preparation for Lithium Battery Materials

>> Acacia Wood Cutting Board Cheese Butcher Block Rectangle Round End Grain Chopping Board

>> Agricultural Machinery Dry Land Wasteland Tractor Trailed Wheel 7seven Blades Hydraulic Heavy Duty Disc Plow Plough

>> Flower Headwear Wedding Headband for Bride Crystal Pearls Women Tiara Bridal Headpieces Hair Jewelry Accessories

>> Full Bands Frequency 10km Distance Jamming Anti Drone Jammer Omnidirectional Uav Counter System

>> OEM Carp Wholesale Fly Hook Carbon Factory Lure Rod Fishing Tackle

>> Customer Design Wooden Key Chain with Logo

>> 2022 Women and Men Fabric Casual Shoes Low Price Flyknit Sock Sneakers

>> Superhouse AS2047 NFRC FPA Standard Exterior Glass Sliding Door Aluminum Sliding Door

>> High Quality Professional Building Deck Floor Roll Forming Machine

>> Hanging Price Tag Holder Extruded Data Strip PVC PETG for Supermarket Shelves

>> Automatic 800kg output coffee grinder air cooled grain pulverizer

>> 6000W/6000watts/6kVA 7000W/7000watts/7kw/7kVA Silent Portable Power Emergency Gasoline Generator with CE Soncap Certificate

>> Industrial Hand Protection Waterproof Rubber Gloves

>> TFT Finger Pulse Oximeter Monitoring Apparatus Oxygen Machine

>> High Speed 10t Manual Full-Automatic Decoiler, Uncoiler Machine 5t 10t Manual Decoiler

>> 50 ohm RF N female to N female right angle Type Connector

>> Custom design printing Wholesale price Print Pullover Hoodies Men

>> Xieli Machinery High Precision CNC Centerless Grinder Grinding Machine Grinding Tungsten and Molybdenum

>> Advanced- Graphite Crucible for Negative Electrode Material Production for Purifying Lithium Batteries

>> OEM Customized Healthy Multiple Repurchase Soda Maker with FDA

>> Golden Cup Customized Disposable Corrugated Paper Ripple Wall Paper Cup Forming Machine for Hot Drink

>> Sinotruk HOWO 12 Wheeler 14~16m3 Concrete Cement Mixer Truck

>> Home Security Stand Alone Fire Warning Smoke Alarm

>> Metal lampshade stainless steel perforated mesh cover

>> Yx28.5-67.5 Batten Roll Forming Machine with Servo Flying Cut 20mpm