Fully Automatic Sheep Feed Pellet Making Machine for Large-Scale Production

| US$17,500.00-59,900.00 | 1 Piece (MOQ) |

Basic Info.

Model NO.

Sheep Feed Pellet Production Line

Processing Object

Mixed Feed

Processing Technics

Crushing-before-Mixing

Screen Mesh

With Screen Mesh

Grinding Equipment Type

Roll Crusher

Pellet Mill Type

Screw Granulator

Bulking Machine Type

Twin Screw Bulking Machine

Expanding Method

Dry Expansion

Condition

New

Applicable Materials Shape

Granular

Warranty

1year

Spindle Speed

2960rpm

Die Diameter

630 mm

Number of Hammers

84

Main Power

22 Kw

Width of Grinding Chamber

650 mm

Productivity

1-100t/H

Voltage

380V / 50Hz

Dimensions

9700*8900*3200 mm

Weight

10500 Kg

Noise Level

Lower Than 75 dB

Feed Size

≤60mm

Discharge Size

10-500 Mesh

Processing Capacity

1-100t/H

Screen Aperture

0.5mm-10mm Optional

Feeding Method

Manual or Automatic

Transport Package

Wooden Box

Specification

1400kg

Trademark

Jastec

Origin

China

HS Code

8436100000

Production Capacity

500pieces/Year

Product Description

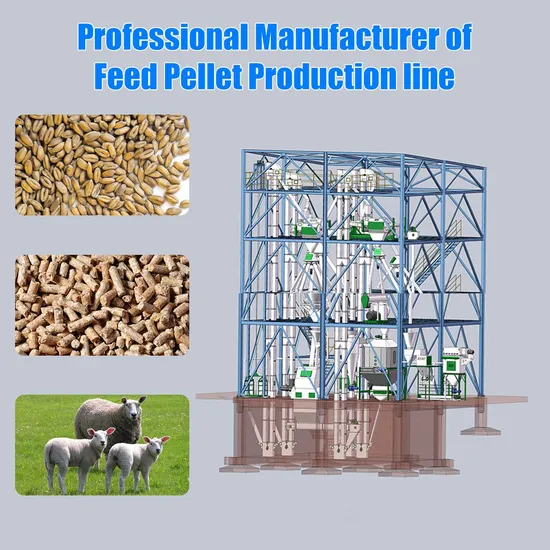

Sheep Feed Pellet Production LineControl Mode: Automatic/Manual

Capacity:1-100T/H

APPLICATION:Sheep Feed Industry

Feed:6-12mm pellet feed and powder Sheep feed pellet production line is used to process sheep feed pellets based on various raw material formulas. It can be installed in feed mills and farms of various specifications. JASTEC offers turn-key project about 1-100TPH complete sheep feed pellet production line, according to the requirement, different output configuration can be customized and provides more value added service to customers. All JASTEC animal sheep feed production lines /complete sheep feed manufacturing plants are tailor-made to suit the customer's specific requirement, which also implies a close dialogue with the client regarding present and future requirements as well as local conditions.

Applications Of Sheep Feed Pellet Production Line Sheep feed production line is mainly set up in sheep feed mills, ruminant feed mills and sheep farms. This integrated feed processing system is mainly used to process Hay Pellets, Grass Pellets, Fermented Feed, Timothy Pellets, Roughage Pellets, Concentrate Feed Pellet, Alfalfa Pellets, Beet Pulp Pellets for sheep and goat.

JASTEC Machinery is one of the very few sheep feed mill manufacturers with the ability to design, manufacture and supply each and every key sheep feed processing machine in the sheep feed production line, as well as designing and building the sheep feed processing plant as a whole.

01

Flexibility of equipment scale

Traditional sheep feed production methods usually require large-scale production and cannot be adjusted according to market demand. However, with a customized chicken feed production line, the situation is very different.

These equipment can be designed and manufactured according to your actual needs, whether you need to produce dozens of tons of feed or just a few hundred kilograms, you can meet your needs.

02

Improved production efficiency

A customized sheep feed production line can not only produce according to your needs, but also improve production efficiency.

This is because these equipment are usually equipped with advanced production technology and equipment, which can realize the automated production process, greatly reducing the need for manual operation, thereby improving production efficiency.

03

Improved Product Quality

In addition, a complete set of customized sheep feed pellet production line equipment can also improve the quality of the product. This is because these equipment have been carefully designed and manufactured to ensure that the quality of the feed produced meets the highest standards.

And, because these equipment can be adjusted according to your needs, they can adapt to a variety of different production conditions, thus ensuring the quality of the product.

04

Improved environmental performance

Finally, a complete set of customized sheep feed production line equipment can also help improve environmental performance. This is because these equipment usually adopts environmentally friendly design and materials, which can reduce the impact on the environment during the production process.

And, because these equipment can be adjusted according to your needs, they can adapt to a variety of different production conditions, which further improves environmental performance.

From customized non-standard models to multi-combination standard configuration models, JASTEC is always in accordance with market trends and customer needs, constantly introducing new ones. In JASTEC Machinery, each sheep feed plants design and sheep feed machine can be customized. Although the sheep feed production technology of different customers is different, we always follow when designing for customers: reasonable configuration, stable performance, convenient operation process, and high economic benefits.

This sheep feed production line is suitable for sheep feed production of various sizes, various hardness, various lengths and various types (concentrated feed/grass-containing feed/pellet feed/powder feed/mash feed). The replacement of wearing parts can be completed quickly, reducing downtime and maintenance time. Reasonable initial sheep feed mill investment cost and low maintenance cost in the later stage.

Plant preparation

Cost to start sheep feed production line

The configuration of the sheep feed production line is carefully designed according to the on-site survey or the actual requirements of the customer, which fully reflects the rationality, effectiveness, applicability, large output, low wear and low operating cost of the sheep feed mill design.

According to different technological requirements, various types of sheep feed machinery are combined to meet customers' different sheep feed manufacturing process requirements.

| 1-2T/H | 47-75KW | 300-500m² | 7-15 Days | 10000-50000 |

| 3-4T/H | 53-165KW | 300-700m² | 15-20 Days | 5,0000-12,0000 |

| 5-7T/H | 68-259KW | 400-800m² | 20-40Days | 7,0000-25,0000 |

| 8-10T/H | 125-410KW | 800-2000m² | 45-60 Days | 150,000-300,000 |

| 12-20T/H | 358-620KW | 1500-3000m² | 60-90 Days | 250,000-580,000 |

| 25-40T/H | 545-870KW | 2000-4000m² | 90-120Days | 45,0000-850,000 |

| 50-60T/H | 710-1120KW | 3000-5000m² | 100-140 Days | 900,000-1,400,000 |

| 60-80T/H | 815-1370KW | 5000-8000m² | 130-160 Days | 1,450,000-1,800,000 |

| 80-100T/H | 1230-1700KW | 8000-20000m² | 160 -190Days | 2,000,000-2,800,000 |

sheep feed pellet production line cases

Currently, our sheep feed production lines have been exported to the United States, Russia, Argentina, India, Brazil, Germany, France, Saudi Arabia, New Zealand, Uzbekistan and other countries.

Design drawings

How to build a new sheep feed production line? According to customer different sheep feed production types, different output configuration can be customized. We devote ourselves to undertaking all sheep feed production line with 1-100 tons per hour and to providing more value added service to all the customers.

JASTEC Machinery provides global customers with a one-stop, complete set of professional sheep animal feed production line solutions (business plan for sheep feed production) to solve the problems of customers, especially pure investment customers, such as technical difficulties and poor understanding of sheep feed equipment, so that the needs and positioning of the project are more clear, and at the same time, the customer's equipment selection range is more concentrated, reducing the cost of energy and financial resources.

If you want to start a new sheep feed pellet line for your sheep feed mill or sheep farm, you should pay attention to the following main processes:

Determine the scale of sheep feed mill. Determine the sheep feed manufacturing process and recommend sheep feed machine. Control mode selection (the degree of automation of the sheep food processing plant). Complete feed mill plant structure selection. Planning the general drawing of sheep feed mill plant site. Due to the influence of various objective factors such as sheep feed raw materials, processes, formulas, project area, local regulations, etc., various technological sheep feed production process and sheep feed equipment configurations have appeared in the actual sheep feed plant design.

Sheep Feed Pellet Production Line Process DesignThe major operations involved in the sheep livestock feed production lines are: raw materials preparation, primary crushing, molasses mixing, fine crushing, pellet making and packaging(optional).

Why Choose Jastec?

More professional and better understand you. 1. Engineers who can work for machinery overseas (all prefectures).

2. JASTEC overseas service centers are available (Showroom in europe,north america,southeast asia).

3. Overseas third-party support is available (europe,north america,asia).

4. JASTEC engineers have more than 15 years of professional experience in the drying industry, engaged in design,mechanical drawing, electrical automation editing, etc.

5. JASTEC have rich experience in project management and advanced on-site construction technology; We have gained

good performanceand a well-known reputation.

Company Profile

Jastec(Shanghai) Technology Co., Ltd is a professional supplier of food deep processing (include food additive) machinery. It integrates develop, sales, after-sale services as a whole, being a professional supplier for extraction equipment, drying equipment, mixing equipment, grinding equipment and turnkey project for food(include food additive)and agriculture industry etc. Jastec has passed the Occupational health and Safety Management System Conforms to the standard CE,SGS etc. As the members of China National Standardization technique Committee for Industrial Equipment,testified by experience of long-term users, our machine and production line have very high stability and reliability, which have been sold to more than 160 foreign countries like Asian, African,European, American. Jastec have established branch offices and showrooms in Europe and North America. For many years, we`re stick to the principle of "Customers First" taken the initiative to manage customers` demands, to develop and research high-quality, low energy cost but efficiency equipment, set up a perfect after-sale service system, and brought up the concept of" Star service" The Jastec equipment is worth of your trust, Let`s join hands to co-develop a brilliant future in the 21st century full of opportunities! Brand from concentration--Our pursuit is to supply the best cost-effective machines in the world. In this 21-century full of opportunities and challenges, Jastec will provide new equipment and more pragmatic spirit of innovation, cooperate with you and create brilliance!

Exibition

Factory Showcase

Packaging and Shipping

>> YAMAHA Nrx 150 Rear Shock Absorber Motorcycle Parts

>> High Quality 1.0MPa Water Supply Parts 1.6MPa Plastic Plumbing Pipe and Fittings PVC Flange Pipe Fitting PVC Pressure Pipe Fitting DIN Standard Dia.20 -Dia.400

>> Disposable ECG Electrode for Adult ECG Monitoring

>> Custom Elastic Band PU Leather Journals Notebook for Office School Students

>> Fast delivery Reinforcement|Rebar Locator and Concrete Covermeter

>> Seaguar R18 Fluoro ltd HARD 80m Fluorocarbon fishing line super high strength japan fishing lines

>> Cx-Mini-Pg Stainless Steel Capsule Mini Bar Gauges (CX-MINI-PG)

>> Digital Chess Clock Wooden Chess Clock Plastic Material Fine Finishing Material Chess Clock

>> Rock Gold Ore Alluvial Gold Ore Jaw Crusher

>> Automatic Animal Chicken Feed Pellet Production Line Poultry Feed Machine

>> Broadcom New Original LSI Cvpm05 05-50039-00 Capacitor Protection Battery

>> Wonyo 8 Head Computerized Embroidery Machine for Cap Flat T-Shirt

>> Ap-28 Wholesale Sports Equipment Black Painted Cast Iron Barbell Weight Plate

>> Farm Tool for Paddy Field 2.8m 3 Point Mounted Paddy Beater Lowest Price

>> China Quality Wholesaler ONIX car Rear body structure tail light bracket R For Chevrolet 26253867

>> Plastic ball Joint head Stainless Steel Gas Spring

>> Vissko Rechargeable 10000mAh Student Dormitory Hanging Tent Hanging Lantern LED Flash Camping Folding Outdoor Portable Light

>> Cotton crop top T-shirt

>> Long Life Proprietary Bending Formula Universal Bending Die Smart Flexible Panel Bander

>> Support Customization Factory Sale Gmc/Gmb1213 Big Size Axis Gantry CNC Machining Center

>> Custom Wholesale Reflective Bands Electric Guitar Bag Padded Gig Bag Soft Case

>> Automatic Machine Mini CNC Lathe Good Price Ck6130 Small CNC Lathe

>> OEM High-Power Semiconductor and Power Electronics Fin Copper Heat Sink

>> Cosmetic High Pressure Homogenizer (GJB1000-30)

>> High Automatization Ycq-5L-2 Automatic Three Parts Injection Molding Machine

>> Dates Fully Automatic Machines for Packing Food And Products Auto Packaging Production Line Packing Machine

>> Xpd-510bi High Performance Multi - Magnification Optical Instrument Stereo Microscopes

>> Free Delivery Mini Excavator 1 Ton CE/EPA Engine Excavator Machine Small Excavator Hydraulic Crawler Excavator for Sale

>> DUI HEI Distributor Mechanical Advance Lock up Plate

>> Food greaseproof paper biodegradable microwave popcorn bling packing bag with reflecting film