Dw50CNC Pipe Bender Machine Chinese Factory

| US$14,769.00-14,899.00 | 1 Piece (MOQ) |

Basic Info.

Model NO.

DW50CNC

Condition

New

Certification

ISO 9001:2000, ISO 9001:2008, CE

Automation

Automatic

Suitable for

Rubber, Copper, Aluminum, Alloy, Carbon Steel, Stainless Steel

Type

Pipe and Tube Bending Machine

Material

Alloy Brass, Copper, Carbon Steel, Stainless Steel

Place of Origin

China

Product Name

New Design Exhaust Pipe Tube Bender Machine 38CNC

Keyword

China Pipe Bending Machine Factory

Voltage

220V/380V/415V/440V/Customized

Servo Motor

Japan

Electric Parts

France S Chneider

Bending Precision

0.1

Brand Name

Bh

Extra Services

China Pipe Bending Machine Factory

Power (Kw)

5.5kw

Key Selling Points

Automatic

Machine Type

CNC Pipe Bending Machine

Color

Support Customized

Control

PLC

Transport Package

Wood Case

Specification

3900× 1840× 1300

Trademark

BH

Origin

Jiangsu

HS Code

8462219000

Production Capacity

1000 Set/Year

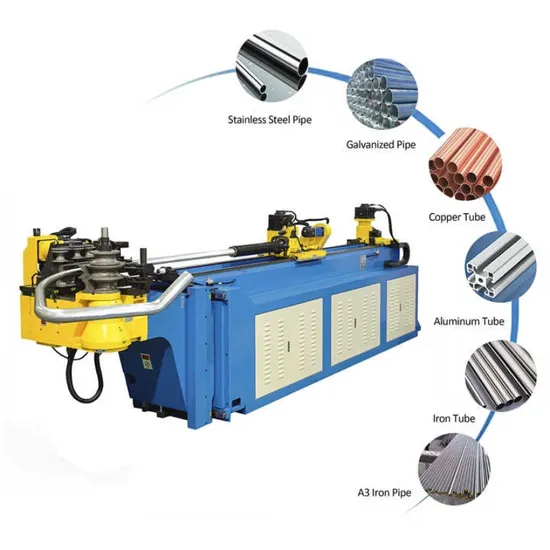

Product Description

Steel pipe cnc auto bending machine for saleProduct Description: Full-automatic pipe bending machine equipped with PLC or IPC which manage Bending (Y), Feeding (B) & Rotation (C) in a complete automatic cycle. Ranging from 10mm up to 220mm OD these machines are suited for use in a wide range of pipe manufacturing sectors and industries. Available in different versions, there's all three axis are automatic in a single stack machine.There's also the option to add push bending function, left and right bending function, more stacks,and so on. The series comes equipped with easy-to-operate touchscreen controls, or with the latest user-friendly 3D bending software. This stores tooling configuration, allows spring-back compensation, and boasts anti-collision technology, amongst other features.

| No. | The main technical parameters | Parameter Value | Unit | Remarks |

| 1 | Maximum bending capacity | Ф38×2 | mm | |

| 2 | The maximum feed distance | 1800 | mm | |

| 3 | Maximum bending angle | 190° | degree | Bending accuracy: ±0.1° |

| 4 | The maximum bending number | 20 | ||

| 5 | Rotation | 0~±360° | degree | Angle accuracy: ±0.1° |

| 6 | Feeding accuracy | ±0.1 | mm | |

| 7 | Bending program memory capacity | 500 | unit |

Product show

Feature * Interactive PLC touch screen offers easy access to auto and manual operating modes.

* System diagnostics and multiple language capability.

* Fully hydraulic clamping on clamp die and pressure die.

* Bending (Y-Axis): Controlled by Servomotor or by Hydraulic.

* Feeding (B-Axis): Controlled by Servomotor.

* Rotating (C-Axis): Controlled by Servomotor.

* Equipped with adjustable speed valve on pressure die ensures the synchronization of bending.

* Air cooling system ensures the equipment long-time work stably under the high temperature.

* CE&ISO 9001:2000.

Bending sample show

Packing & Shipping

Warehouse

After sales-service After the machine is installed in buyer's factory, 365 days later, if any parts are damaged because of quality,

the seller will give new parts for free

If any problem happens to the machine, Seller agrees to assist the Buyer in repairing the machine

through email or phone call. In case the presence of Sellers technician is required for repairing the machine,

the Buyer will pay for the tickets and accommodation of visiting technician.we need to know several parameters before recommend the suitable model

1. what product are you going to produce with pipe bending machine

2. what is the pipe material ?

3. what is the pipe OD and thickness

4. what is the bending radius

5.how many angles on one pipe

6 what is the pipe length?

5. if you have bending drawing, please send it to me, so that we can know your technical requirement . just like the bending

drawing as aboved

>> Luxury Ins Fashion Promotional Pearl Necklace Stainless Steel Metal Bracelet Branded Designer Wholesale Ring Replica Online Store 1: 1 Jewelry Earrings Necklace

>> Custom 2022 Fashion Professional Classic Shirts with 100%polyester

>> a Type Layer Chicken Battery Cage in Poultry Farm Hot Sale in Nigeria Kenya Zambia Uganda Tanzania

>> New Design Alloy Wheels Rims

>> China Factory Reliable Manufacturer 30000 BTU 2.5Ton Split Klimaanlage R32

>> Custom High Quality Aluminum Waterproof Food Wrapping Film Candy Potato Chips Chocolate Sachet Bakery Packaging Mylar Bags

>> Spc Flooring Production Line Mixing Machine for Vinyle Floor

>> factory ha 2ml 20ml hyaluronic acid cross-linked facial fillers dermal filler wrinkle injection

>> Newly designed reverse osmosis enclosure affordable 4" membrane

>> 100W 200W 300W Suitcase Type Metal Surface Removal Rust Pulse Laser Cleaning Machine

>> Taijia concrete rebar corrosion detector concrete scanning services Rebar rust detector

>> Premium UV Resistant Beach Umbrella with Adjustable Features Sun Parasols Outdoor UV Resistant Stripe Beach Garden Backyard Coffee Umbrella

>> 130426-00024 Swing Motor with Gearbox Dx480lca Dx500lca Dx520lca Swing Device for Doosan Dx520

>> 4 Burners Glass Top Foldable Gas Home Appliance Cooktop Stove Hob

>> 5t057-71720 Sieve Spare Parts for Kubota Combine Harvester DC68 and D70

>> Disposable Stainless Steel Surgical Blade Scalpel Bistoury

>> Nvidia Jetson Agx Orin 64GB Module (PN: 900-13701-0050-000)

>> Factory Direct Price Concrete Mixing Plant Machine Batching Machine Lightweight

>> Servo-Driven High Speed 4 Cavities Automatic Plastic Pet Mineral Water/Juice/Wine Bottle Making Blow/Blowing Mold/Moulding/Machinery/Machine

>> Long Distance Thermal Surveillance Camera Explosion Proof Hot Spot Alert

>> Industrial Flying Model Fiber Laser Printer for Pipe

>> Construction Equipment New Crawler Hydraulic Mini Excavators Wheel Excavator Mini Digger Amphibious Excavators with Excavator Parts Factory

>> Ergonomic Electric Motorized Height Adjustable Sit Stand Desk

>> High Efficiency Vertical Milling Siemens System Easy to Adjust Angle High Speed Cutting Universal Milling Machine

>> Free Shipping 3.5 Ton Earth Moving Machinery Mini Excavator for Sale

>> High Purity 99.9% Metals Basis, ≤ 0.8μ M 30~50nm Nano-Tungsten Carbide Powder

>> Automatic Grain Feed Rotaty Distributor with 4-12 Outlet Holes

>> AAA Quality Natural Genuine Cultured Freshwater Nucleated Baroque Loose Pearls (XL110043)

>> Universal Milling Machine/Vertial Milling Machine XL6230

>> XIAOMI MIJIA Handheld Vacuum Cleaner For Home Sweeping 16000Pa Strong cyclone Suction Multi functional Brush Dust Catcher