C-Channel Roll Former Machine for Light Gauge Steel Framing Roll Forming

| US$110,000.00-160,000.00 | 1 Piece (MOQ) |

Basic Info.

Model NO.

SFS-CC75-200T

Certification

CE, ISO9001

Customized

Customized

Condition

New

Control Type

CNC

Automatic Grade

Automatic

Feeding Material

Galvanized Sheet(Gi), Cold Roll Steel(CRC), Hot RO

Yield Strength

250-450MPa

Punching

Service Hole, Dimple Hole, Web Notching

Thickness

0.75-1.6mm

Profile Width

75mm-200mm

Profile Flange

41mm

Profile Lip

10mm -15mm

Cutter Material

Cr12 MOV, Cr12, Cr12(Total Three Blades)

Control System

PC Control

PLC Brand

Japan Panasonic

Decoiler

Hydraulic Decoiler

Total Weight

8,000kgs

Size Changing

Auto Size Changing for Rollers

Blade Replacement

Manual Blade Replacing

Main Motor Power

3.0kw, 60Hz, 380V

Transport Package

Naked

Specification

(length)16m x (width) 1.7m x (height) 2.0m

Trademark

FrameTec

Origin

China

HS Code

8455221000

Production Capacity

600 Sets/Year

Packaging & Delivery

Package Size

1600.00cm * 170.00cm * 200.00cm

Package Gross Weight

10000.000kg

Product Description

Metal Steel Roll Framing Machine SFS-CC75-200 for 1-5 storey Residential House/HotelTECHNICAL PARAMETERS I. Specifications

| Machine Quick Details | |

| Model number: SFS-CC75-200 | Condition: New |

| Type: LGS machine | Brand Name: Frametec |

| Thickness: 0.75-1.6mm | Control System: PC control |

| Warranty: 1 year | Place of Origin: China |

1) Profile width: 3 " to 7.87" (75mm to 200mm)

2) Profile flange: 1 5/8" (41mm)

3) Profile thickness: 16-22 gauge (0.75mm-1.6mm)

4) Material : galvanized coil sheets: ASTM A1003 & ASTM A653

5) Max yield: 250Mpa-550Mpa 80ksi at 1.6 mm (16ga) material thickness.

The range of web size is 3" to 7.87" (75-200mm) ,Each of the size rangewill have related chamfer cut tooling and notch cut tooling. So this machine can be easily exchange punch tools when produce difference size of steel profile.

II. Machine Components Hydraulic de-coiler ------------------------------------------------------------------- 1 set Leveling Device ----------------------------------------------------------------------- 1 set Pre-punching Device --------------------------------------------------------------- 1 set Roll Forming System --------------------------------------------------------------- 1set Post-punching Device -------------------------------------------------------------- 1 set Cutting Device ----------------------------------------------------------------------- 1 set PLC Control System ----------------------------------------------------------------- 1 set Out-let Table -------------------------------------------------------------------------- 1 set III. Flow Chart

The flow chart is showing below.

De-coiler→ Leveling Device→ Pre-punching Device→ Roll Forming System→ Post-punching Device→ Cutting Device →Out-let table

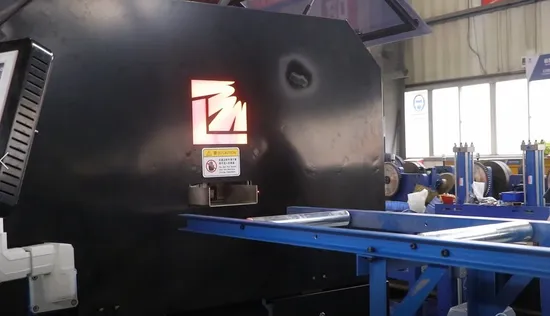

IV. Machine Pictures

V. Technology Parameters

The weight of the Machine: About 10 Ton

The total dimension with un-coiler, Out-let Table is:

(length) 16m x (width) 1.71m x (height) 2m.

The dimension of forming parts: (length) 8m x (width) 1.71m x (height) 2m.

1)Hydraulic de-coiler (The hydraulic de-coiler is excluded in this quote)

De-coiler Type: Hydraulic auto de-coiler Weight capacity: Max 5.0T Diameter of inner: 480-510mm Diameter of outer: 800mm Motor power: 3.0Kw,60Hz, 380V(Customized) Control type: Electric button control Function: Auto rotation feed sheets into roll forming parts. Semi auto for loosening and tightening coil Weight of de-coiler: 1000KGS. Side Locks provided on de-coiler to fix coil.

2) Punching

All punching dies are made from Cr12. Driven by hydraulic station. Holes parameter are able to set by PLC, Including Punching length and numbers.

Four leveling devices is used to fasten the raw material. When punching system is on working, the raw material will be fixed tightly by leveling device to ensure the job precision. Hydraulic station: 11 kw + fan cooling system Driven by servo motor. Hole Type: a. Right flange punching

b. Left flange punching

c. Web triple hole

d. Bolt hole

e. Online-swage

f. Truss cut

h. Web notch

i. Dimple

j. Service hole

k. Lip cut

Pre-punching holes: 1,2,3,4,6,7,9,10

Post-punching holes: 5,6,7,8

1. Punching precision within +/-0.03937'' (+/-0.5mm)

2. After hole punching, raw material will be driven into roll forming system.

3) Rolling Forming System Main motor type: 3 phases Main motor power: 14Kw, 60Hz, 380V (suits Australian power requirements) Servo motor brand: INNOVANCE Speed of forming: 98'/min (30m/min) Combine speed: 16.5'-39'/min (5-12m/min depending on No. of holes) Roller: 17 groups rollers. Roller Material is Cr12 mould steel being quenched treatment, with digital-controlled procession. This ensure rollers are all on good condition and long life. Shaft & Frame: Shafts of rollers are tooled by grinding machine for two times to ensure the precision of final product.

4) Changing Size Full-automatic (change sizes by PC control system) Machine is designed to change profile size within 1 minutes. This type of system is easy to operate. Only need to set the profile specs on the control panel, the roller stands will move in and out automatically. Size range: Web: 75-160mm Flange:1 5/8" (41mm) Lip: 8 - 16mm Size changing motor power: 0.4kw, 380v, 60Hz, totally 5 sets.

5) Hydraulic Cutter Cutting material: Cr12 Cr12MoV Cr12(total three blades) Hydraulic motor power: 11KW Hydraulic Pressure: 16Mpa

6) Out-let Table

4 meter material receiving table, with a stacking platform.

To consider easy for shipment. The components of Out-let Table will be well packaged and will be installed at Buyer's warehouse.

7) Safety Guard: Safety Guard covers the whole machine to ensure worker's safe.

Each parts of safety guard is linked with lock. Safety switch is available to stop machine when safety guard is open.

8) PC control system LG-R1. The control system has capacity to program production CNC by inputing Dahe's TXT to CSV format and connect with machine directly. It can control machine auto-running and running status dynamically, including punching, cutting and size changing. Manual length/punching program of production The computer can control production line including leveling, punching, cutting, conveyer table and roll forming station. Speed of the machine can be adjusted. The choice production data can be showed on screen.

9) Profile image and application

10) Our Factory

Why Choose us:

13+ years manufacturing experience in hight-quality roll-forming equipment

Competitive price and good quality

One year free warranty

Fast response of after sale service

Can be customized by clients' requirements

Easy operate and easy to maintain

Self-developed of post cutter, one blade to cutter all size of final product

>> Lifetime warranty CE making machine Hurricane Storm Slide Double Glaze White UPVC european windows

>> FRP Pultrusion Profiles Production Machine Kinds of Profiles Production Line

>> Comfortable Wholesale Vest Made to Order Sportswear.

>> MR-13D industrial easy work drill sharpening machine with CBN wheel

>> PVC PP Brass Insert Thread Pipe Fitting Injection Mould

>> Factory Wholsale Lowest Price 12V 24V AC Hose Crimping Machine

>> Popular Heavy Duty Dongfeng Tianlong 25000kg Compactor Garbage Truck Efficient Waste Disposal Large Diesel Compression Special Vehicle Best Quality 5250

>> Yada Biodegradable Disposable Wooden Flatware Fork Knife Dinnerware Weddings Wooden Spoon Knife Forks Set For Fast Food

>> New Technology 2850mm Crescent Type Toilet Tissue Paper Machine

>> Bearing Cage Stainless Steel Aluminum Die Casting

>> Taijia ZBL-P8100 PIT apparatus Foundation Pile Dynamic Detector Concrete Pile Tester

>> Custom Keep Warm Motorcycle Thermal Food Pizza Delivery Bag Bike Box

>> ANSI Cast Steel Globe Valve, Flange End RF/Rtj, 150lb/300lb/600lb/900lb, CF8/Wcb

>> Perfectly Balanced for Tough Jobs 34.3t – Discover The Power and Precision of Our Medium Excavator Bucket Digging Capacity 220kN Medium Excavator Sale

>> Taijia fixed ultrasonic flow meter ultrasonic flowmeter sensor clamp on ultrasonic open channel flow meter

>> Hg89 Steel Pipe Production Line

>> Economic New Type Honeycomb Core Production Line

>> Delem Da53t Controller Press Brake Hydraulic Bending Machine System Operation Manual

>> High Quality Fresh Potato for Sale Factory Price

>> China air filter end cap With free sample service

>> 2022 Hot sale best quality fishing metal cheapest fishing spinning reel

>> 2024 Custom Printing Biodegradable Round Gift Paper Tube Packaging for Loose Tea Package

>> X18 720p Kids Gifts Instant Print Mini Digital Camera for Boys Girls

>> Forged Hammer Pattern Viking Stainless Steel Meat Cleaver Butcher Knife kitchen vegetable knife set with sheath

>> Solar Tracking Reducer Slewing Drive Large Output Torque Sun Tracker

>> Water Drop Wooden Medal Stand Combination Heart-Shaped Medal Display Stand

>> Double Columns CNC Gantry Machining Center Machine Lm2214 (2200*1100)

>> Cotton Plain Tassel Wool Shawl Pashmina Scarf Cashmere Winter Silk Shawls

>> Economical Servo Motor Injection Molding Machine for Pet Plastic Preform Mold

>> Xinjiang Tomato Paste Concentration 28-30% Hot Break 220L in Drum