Rabbit Fur Raschel Warp Knitting Machine Double Needle Bar Double Needle Bed Machine

| US$30,000.00-100,000.00 | 1 SET (MOQ) |

Basic Info.

Model NO.

AZ2885

Knitting Product Type

Carpet

Knitting Style

Warp

Knitting Method

Double

Needle Style

Latch Needle

Needle Bar Style

Warp Knitting Machine

Computerized

Computerized

Certification

CE

Condition

New

After-sales Service

1 Year

Machine Width

90", 110", 138", 190"

Needle Bar Material

Aluminum

Machine Weight

7000kgs

Transport Package

Wooeden Pallet

Specification

gauge 16; gauge 18; gauge 20; gauge 22

Trademark

A-ZEN

Origin

China

HS Code

844720

Production Capacity

30 Sets/Month

Product Description

Product Description

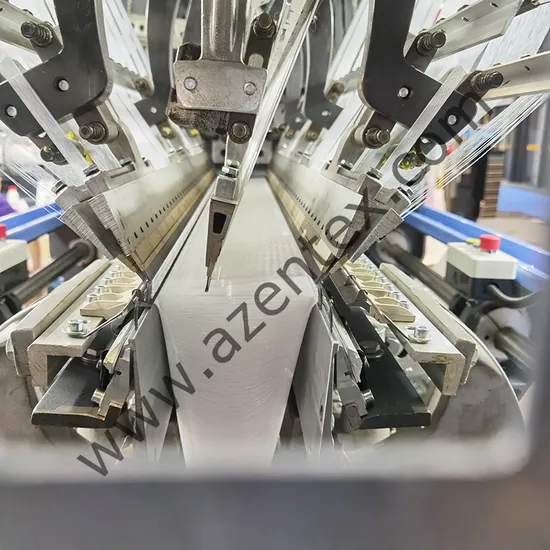

A-ZEN rabbit fur double-needle bar machine is one of the most welcome machine types among the AZEN products family.

This machine is specialized in developing apparel fabrics, plush toys, and upholstery fabrics.

Detailed Photos

| Working Width | 90", 110", 138", 190" | Yarn Let-off Device | EBC Electronical Let-off |

| Bars Number | 5, 6, 7 | Fabric Take-up Device | Electronical Take-up Device |

| Knitting Element | Individual Needle | Beams Size | Φ21"-Φ30", Φ21"-Φ40" |

| Pattern Drive | Pattern Disc or EL | Main Power | 4KW(110"), 7.5KW(138") |

Application

FAQ

Q: what is the knock-over comb distance of the flannel double needle bar warp knitting machine? A: The double needle bar raschel warp knitting machine for flannel fabrics knock-over distance is from 8mm to 150mm.

Q: What is the popular gauge for the blanket machine A: Most customers choose gauges 18 and 22.

Q: How do you ensure your double needle bar raschel machine quality A: Firstly, we produce and provide lots of machines to the market, and our machines' lifespan and quality ensured by different markets over the years.

Secondly, we largely use renowned and market-tested spare-part brands, to make sure the mechanical and electrical parts are durable.

Besides, we have regular service to customers, to check the quality of our machines and remind customers of maintenance, so our customers could run machine always in stable performance.

Our Advantages

In-house Sampling Production

In order to test our double needle bar raschel machines' performance, as well as to adjust machine specifications to fit customers' fabric quality, we provide in-house sampling production before the machine delivery. We analyze fabric structure, make a design sketch, and make a record of the knitting process. Our customers could have access to acknowledge our double needle bar raschel machine performance during real production, but also obtain the knitting production data which is helpful during their mass production.

Local Engineers Installation & Training

We build up serval overseas technical service teams in India, Turkey, Indonesia, Pakistan, Iran, and Egypt. Those well-trained engineers have rich skills and experience for the double needle bar raschel machines installation and production. Our service includes Warping Machine installation, Double-needle Bar Raschel Machines installation, Tricot Machines installation, and Tricot Terry Warp Knitting Machines installation. What's more, our overseas engineers could provide warp knitting basic knowledge and maintenance training for our double needle bar raschel machines. Customers could contact A-ZEN China or A-ZEN overseas office to get this service.

Online Support

All A-ZEN double needle bar raschel machines are equipped with an online service program, and thanks to this, a faster and more accurate service become available. Online Support refers to running faults rectification and machine system checks and protection. So far, we have many successful online support service stories in Turkey, India, Pakistan, and other places, and our customers enjoy a pleasant service that enables their double needle bar raschel machines to be productive ones.

Routine Maintenance

We send notifications to our double needle bar raschel machine users regularly, especially after the machine works more than two years. Routine maintenance notification plays a vital role when the machine is under poor maintenance conditions. We hope our routine maintenance service could largely avoid production loss because of the inefficient maintenance of the double needle bar raschel machines.

>> PFSK130 3BSE002616R1 ABB module supply

>> Space divider decorative round hole perforated metal mesh product

>> Omri Soya Based Enzymatic Hydrolysis Amino Acid Liquid 50% Liquid Amino Acid Fertilizer

>> Commercial Eco-Friendly Wood Crusher Machine Wood Chipper Machine Shredder Tree Branch Shredder

>> Shenone China Supplier Wholesale Cheaps 100% Pure Linens Bedroom Blackout Curtain for The Living Room Ready Made

>> 9060 CO2 Laser Engraving Machine Acrylic Wood MDF Leather Cloth Cutting

>> Wholesale 1-3cm, 3-5cm, 5-8cm, 8-15cm Organic Pine Bark Wood Chip Mulch for Plant Protection

>> IP Video Intercom Door Camera with Monitor Video Door Phone System

>> Precise Panel Saw with Ce Approved

>> Carbon Steel Rear Shelf/ Metal Bracket Carriage/ Frame Stamping Welding Metel Part /OEM Motorcycle Spare Part

>> Professional Pet Cleaning Grooming Kit Dog Hair Trimmer Grooming Clippers Dog Hair Shaver

>> Br-200L Slant Type Price of Lathe Machine CNC Slant Bed High Precision Metal Slant Inclined Bed CNC Lathe Machine

>> CAT6A FTP LAN Cable, High Speed CAT6A FTP Network Patch Cable

>> 3 Axis Stone 4 Axis Stone CNC Router 1325 4X8 with Servo Motor and Drivers for Granite Carving and Cutting Machine

>> High quality 100% natural gardenia blue powder with edible colorant

>> YFMC-720B Manual Split Photo Laminating machine for Printing Office

>> High Reflective ABS Plastic Road Stud with More Than 25 Tons Compressive Strength

>> Factory Price Wholesales Automatic Packing Machine For Bar Soap Washing Soap

>> High Speed CNC Wire Cutting Machine with Taper Angle Dk7763

>> My-B129 Medical Laboratory Equipment Portable Biological Microscope Binocular

>> LED Professional Smoke Machine DJ Show Party Equipment 500W Fog Machine RGB Wireless Remote Control Lights

>> Coffee machine 600 ml drip type tea automatic heat preservation

>> High Speed Condiment Powder Horizontal Double Shafts Paddle Mixer

>> Versatile 17-Inch Laptop 4-in-1 Large-Capacity Business Travel Backpack with Multiple Compartments for Ultimate Organization

>> hot sale custom logo polo t shirt for men wholesale price men polo shirts

>> Hygienic Stainless Steel Kscp Series Sanitary Close Impeller Centrifugal Pump

>> XT8980A XTIOT China 4G 64G Android 10.0 13.56 RFID NFC Portable Data Terminal Handheld Barcode Scanner With Printer

>> LDPE PE Plastic Ball Making Machine Different Children Toy Supplier Blow Molding Machinery

>> Yokohama Type Floating Marine Rubber Pneumatic Fenders

>> 12L HDPE Jerry Can Full Automatic Blow Molding Machine