Plastic HDPE PE PP PVC Single Wall Double Wall Corrugated Dwc Sewer Water Drainage Pipe Hose Tube Extrusion Production Making Manufacturing Machine

| US$15,000.00-50,000.00 | 1 Set (MOQ) |

Basic Info.

Model NO.

SJ65

Screw No.

Single-screw

Automation

Automatic

Computerized

Computerized

Certification

CE, ISO9001:2008

Customized

Customized

Condition

New

After-sales Service

Yes

Main Motor

AC

Inverter

ABB

Main Electrics

Siemens

Temperature Control

Omron

Machine Color

White, Grey or According to Requirement

Transport Package

Wooden Case, Film Packing

Specification

16-63mm

Trademark

Sunrise Machinery

Origin

China

HS Code

84778000

Production Capacity

100 Set /Year

Packaging & Delivery

Package Size

400.00cm * 180.00cm * 180.00cm

Package Gross Weight

3000.000kg

Product Description

Product DescriptionPE Single Wall Corrugated Pipe Extrusion Making Machine / Double Wall Corrugated (DWC) Pipe Machine

The Single Wall corrugated pipe line includes single screw extruder, extrusion mold, pipe corrugate calibration machine, double winder, etc.

The Double Wall Corrugated Pipe machine includes two set single screw extruders, DWC corrugated machine, cooling tank, cutting machine and stacker. The DWC pipe is mainly used for sewer pipe water drainage.

If you need this machine, please tell us the pipe diameter you want to produce, we will make the right offer for you.

Single Wall Pipe Line

| Model | Pipe Diameter (mm) | Motor Power | Speed (m/min) |

| SJ-45/30 | 16-32 | 11 | 1-10 |

| SJ-50/30 | 16-40 | 15 | 1-12 |

| SJ-65/30 | 16-63 | 22 | 1-12 |

If you need good pipe production line, please contact us now.

Double Wall Corrugated Pipe Machine DWC pipe machine

PVC pipe machines

PVC & UPVC Pipe Production Line is used to produce PVC & UPVC Pipe with different diameter and wall thickness which is widely used in agricultural water supply, drainage pipe, electric conduit pipe and so on. CPVC pipe machine is available.

Feature of Machines:

1- PLC control, high degree of automation

2- Adopting special screw and barrel, good effect

3- Adopting compound spiral engine head, effectively eliminate memory function of the material

4- Easy operate and need less worker

5- Convenient for maintaining

Produce process:

PVC powder + additive →mixing →spring feeding →twin screw extruder →mould and calibrator → vacuum forming machine →haul off machine →cutting machine →stacker

Technical Parameters:

| Diameter(mm) | 16-40dual | 20-63dual | 20-63 | 75-200 | 160-315 | 315-630 |

| Extruder mode | SJZ51/105 | SJZ65/132 | SJZ51/105 | SJZ65/132 | SJZ80/156 | SJZ92/188 |

| Extruder power (kw) | 18.5 | 37 | 18.5 | 37 | 55 | 110 |

| Max lineal speed (m/min) | 0.5-10 | 0.5-15 | 0.5-10 | 0.5-8 | 0.5-6 | 0.5-4 |

| Max capacity (kg/h) | 120 | 250 | 80-120 | 180-250 | 300-450 | 500-600 |

Main Composition of PVC Pipe Making Machine:

| No. | Item | Quantity |

| 1 | SJSZ series conical twin screw extruder (Equipped with automatic feeding unit) | one set |

| 2 | Die and Mold | One set |

| 3 | Vacuum calibration water tank | One set |

| 4 | Haul-off unit | One set |

| 5 | Cutter Unit | One set |

| 6 | Stacker | One set |

| Optional auxiliary machines in production for your choice | ||

| A | Printer | one set |

| B | Mixer | one set |

| C | Crusher | one set |

| D | Milling machine | one set |

| 5 | Belling machine | one set |

FOR HDPE PPR pipe machines, we use high efficient single screw extruder to produce. The process is mixing PE / PPR material with color, and feed into extruder for production. There are color line extruder to mark 1 or 2 or 4 color lines according to your requirement. For different diameters, we will use different model machines.

Services:

1. We could send engineers to the buyer's factory for installation instruction, commissioning and training service at buyer's cost.

2. Our machine has one year guarantee since the installation in buyer's factory. During the guarantee time, if any parts (except the easy damaging parts) are damaged under normal operation, we will offer free spare parts. After the guarantee time, we will offer the spare parts with cost price.

3. If the buyer has any problem during the operation, we will offer technical solutions.

Detailed Photos

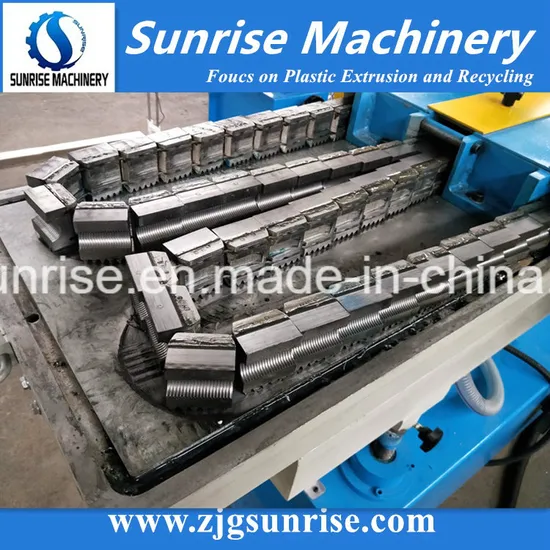

1. Conical Twin Screw Extruder for PVC Pipe Production:

PLC computer control available

2. High Effeicient Sinlge Screw Extruder (L/D 33:1 or 38:1) for PE PPR Pipe Production:

3. Color Line Extruder for HDPE PPR PVC Pipe color line marking

4. Vacuum Calibration Tank ( for PVC HDPE PPR pipe)

(vacuum tank is made of stainless steel SUS304)

6. Cooling Tank for HDPE PPR and Larger Diameter PVC pipe

(made of stainless steel SUS304 with quality glass)

7.Haul off Machine for PVC HDPE PPR pipe

( 2 claw, 3 claw, 4 claw, 6 claw, 8 claw , 10 claw caterpillaer available)

8. Cutting Machines (Planetary Cutter and Non dust cutter)

9. Stacker for PVC HDPE PPR pipe and Winding Machine for HDPE (20-110mm)

10. Laser Printer for printing pipe info

Company Profile

Zhangjiagang Sunrise Machinery Co., Ltd. is specialized in manufacturing kinds of plastic machines. Sunrise Machinery is located in Zhangjiagang City, Jiangsu Province, 150km away from Shanghai.

Our main products as below:

1. PVC / PE / PPR Pipe Production Line

2. PVC window & Door Profile / Panel Production Line

3. Plastic Sheet & Wide Board Production Line

4. Plastic Shredder, Crusher & Pulverizer

5. Waste Plastic Recycling Machines

6. Wood Plastic Profile Production Line

7. High Speed Mixer for PVC

Our Services:

We have more than 10 years experince in this field. With CE standard and rich experince, Sunrise Machinery will be your reliable supplier for plastic machines. We warmly welcome friends from all over the world to visit our factory.

1. We could send engineers to the buyer's factory for installation instruction, commissioning and training service at buyer's cost.

2. Our machine has 12 month guarantee since the installation in buyer's factory. During the guarantee time, if any parts (except the easy damaging parts) are damaged under normal operation, we will offer free spare parts. After the guarantee time, we will offer the spare parts with cost price.

3. If the buyer have any problem during the operation, we will offer technical solutions.

With more than 10 years experince and focus on plastic machines, Sunrise Machinery will be your good choice.

>> FRP Flap Gate, Fiberglass Flap Gate, FRP Back Prevention Valve

>> 762mm AG Rubber Track for John Deere 8rx Rear R571660 F30ca03575 Tr129219 Crawler Tractors

>> V7768-322001 GE

>> Hand-held steam ironing machine household hand-held vertical ironing machine mini ironing electric iron

>> 4040 FRP Membrane Housing Reverse Osmosis Water Treatment FRP Membrane Housing

>> High Quality HDPE Non-slip Construction Mud Mat for Provide Stability for Rigs

>> Automatic hydraulic oil extracting machine/oil press machine for olive,palm,groundnut,sesame,soybean,coco

>> High Precision Grinding Machine Price My1224 Hydraulic Surface Grinding Machine Senmo

>> Steel Frame CAD Machine for Villa House

>> 2418F705 Housing Rear Seal for Perkigns Engine Oil Seal

>> Best Selling Headlight W166 LED Auto Headlight Suitable for Mercedes Benz Car Accessories Car Headlight

>> 0.7m3 Portable Diesel Mini Small Cement Truck Mixer for Sale

>> high efficacy high quality sausage wire bundling machine, bundle sausage tying machine

>> High Quality Flexispot Desk Modern Modular Office Furniture Workstation

>> Professional abs ultrasonic plastic welding machine for abs plastic products

>> Ultra-Thin LED Downlight Recessed Commercial Household Downlights 6W/9W/12W/18W/24W/10W/15W

>> Custom CNC Services Stainless Steel Copper Aluminum Alloy Wire EDM Laser Machining Parts

>> Qt8-15automatic Concrete Block Making Machine

>> Best Price Customized Stainless Steel Mixing Tank Electric Heating 50L 100L Detergent Shampoo Gel Hand Soap Body Cream Liquid Soap Dispersion Mixer

>> Plastic Rectangular Trays Thermoforming Machine

>> 2600 Toilet Rewinder Machine Tissue Paper Making Machine

>> Taijia Concrete detection with ultrasound (NDT Pulse Tester)

>> 1t Low Headroom and Super-Low Lifting Loop Chain Electric Hoist

>> Efficient Production with Low-Cost Customized Plastic Mould for Cabinets

>> Ribbon Industrial Powder Mixer/ Ribbon Blender/ Powder Mixing Machine

>> Soild Plaid Jacquard Table Cloth Elegance Wrinkle Resistant Contemporary Woven Decorative Tablecloths, Kitchen-Table-Textile

>> Automotive Body Parts Car Bumper For Mercedes V Class Vito Upgrade BARS Body Kits Front Grille Side Skirt Rear Diffuser With Tip

>> Brass Valve Steel LPG Tank Propane Gas Cylinder 12.5kg for Kitchen Cooking

>> 07AC91C

>> 12/14/16 Inches Low Noise Two Roll Rubber Mixing Mill Rubber Mixer