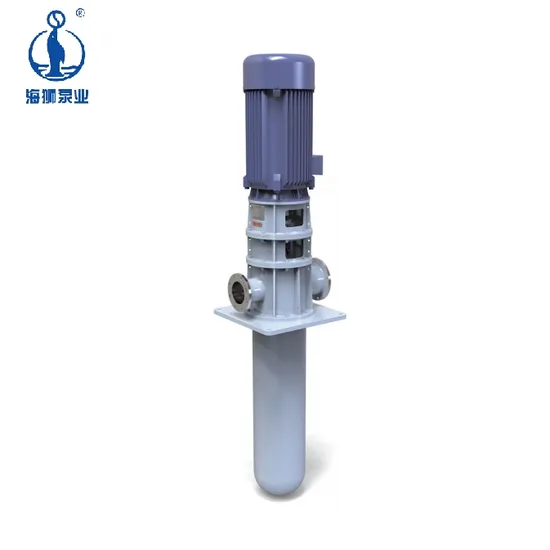

Hlj Vertical Slurry Pump (VS5)

| US$500.00-50,000.00 | 1 Piece (MOQ) |

Basic Info.

Max.Head

30-50m

Max.Capacity

>400 L/min

Driving Type

Motor

Impeller Number

Single-Stage Pump

Working Pressure

Low Pressure Pump

Influent Type of Impeller

Single Suction Pump

Position of Pump Shaft

Vertical Pump

Pump Casing Combined

Verticaljoint Surface Pump

Mounting Height

Suction Centrifugal

Impeller

Closed

Usage

Pump, Pumps, Circulating Pump

Standard

API610

Temperature

-20~150 Degrees

Pressure

~1.6MPa

Head

~50m

Rotation Speed

~1450r/Min

Capacity

400m3/H

Transport Package

Plywood Box

Specification

1000.00cm * 2000.00cm * 1000.00cm

Trademark

haishi

Origin

Jiangsu, China

HS Code

8413709990

Production Capacity

5000

Product Description

| demonstration of the type | range of application | performance parameter |

| 80HLJ-25 80: Flow rate (m³/h) HL series code name 2 5: Lift (m) | Especially suitable for conveying phosphoric acid, ammonium phosphate slurry and other media in phosphate fertilizer industry. Can also be used in oil refinery, petrochemical, coal chemical, power plant, Environmental protection engineering, sewage treatment, cement plant and other industries and fields. | Flow rate: ~400m³/h Head: ~50m Speed: 1450r/min Design pressure: ~1.6MPa Operating temperature: -20ºC~150ºC |

HLJ series slurry pump is a single stage single suction vertical cantilever centrifugal liquid pump. The impeller is semi-open, with wear-resistant covers at both the front and back of the impeller, which is widely used in chemical process to transport the grinding and corrosion interaction media containing less than 30% solid particles and the viscosity is less than 200CP.

The conveying medium is generally lower than 110 ° C. If you need to transport a higher temperature medium, you should consider cooling the bearing with cooling water.

Company profile We offer integrated solutions from embryo casting to complete machine with short lead time and controlled quality.

Main product

workshop

exhibition

Certification certificate

Cooperative brand

APPLICATION AREA

Coal chemical Industry,petroleum and petrochemical Industry,natural gas chemical Industry,fine chemical Industry,etc

Chemical fiber, desulfurization and denitration, etc

Thermal powerthermal power generation,biomass power generation,etc

Mining development,nonferrous metal smelting,Iron and steel metallurgyetc

Environmental protection,wastewater treatment,evaporation and concentration,MVR,etc

Ocean engineering,etc.

New energy, lithlum battery Industry, etc

PACKAGING & TRANSPORTATION

WHY CHOOSE US?

5 DECADES

Established in 1977, long history of pump making brings us rich experience, making us a professional pump manufaturer and ranking us as a famous pump factory in China.

500+ STAFFS

Well trained and professional engineers and workers guarantees the in time delivery and offers professional pump solutions to our clients.

100000m2 WORKSHOPS

Large and modernized workshops and facilities enables the efficient and strict QA&QC procedures and therefore assures the qualified products.

20+ BRANCHES

Established 20+ branches offices and subsidiaries throughout China, they offer closer and in time services to our clients. And our overseas customers are from different places of the world.

3000+ CLIENTS

Own more than 3000 clients both in China and overseas, which is an approval of our product quality and a praise of our service.

20+ PATENTS

Gained more than 20 patents, which is a strong proof of the ability of R&D and a backup of product quality.

FAQ

Q: How long is your factory history?

A: Our factory was established in 1977.

Q: How many staffs does your factory have?

A: We have around 500 staffs.

Q: What international certificates does your factory have?

A: We have API, CE, ISO9001...

Q: Does your factory have foundry for yourself?

A: We have our own foundry in our factory.

Q: What after sales service your factory can provide?

A: Generally, most of the issues can be solved by free guidance of video calls. But paid site service is also available.

Q: What is your product warranty?

A: 12 months since commissioning or 18 months after shipment,whichever is earlier.

Q: What is your factory's annual output capacity?

A: Around 20,000 pcs of various type of pumps.......

>> 2 Wheel Cheap New 500W/800W 60V/48V Optional E- Scooter Electric Bicycle Electric Scooter Electric Motorcycle

>> Top Quality Farrowing Stall for Sale

>> Used Hitachi Zx75 Excavator with Good Working Condition for Hot Sale, Selling at Low Price

>> High Quality 1325 CNC Router Woodworking Machine CNC Routers for Sale

>> High Efficiency Manual Concrete Blending Mixer Equipment

>> Wooden Frame Modern Kitchen Cabinets Shaker White Kitchen Cabinet Sets for Apartment

>> Wholesale GPU Graphic Card Nvidia 3080 3090 Nvidia Chipped Graphic Card Video Card Gaming Hashrate 97mh 120 Mh GPU Eth Ltc Zec Rig

>> Rice Harvester Wheat Harvester Reaper

>> Building Material Kitchen Products 201 304 310 316 Mirror Finished Diamond Checkered SS316L Chequered Stainless Steel Plate

>> Diesel Mobile M7mi Twin Hydraform Brick Machine Soil / Clay Interlocking Brick Making Machine

>> Polyurethane Binder Used Together with EPDM or SBR Granules

>> Certified Factory CNC Machining Services 3D Printing Manufacturing for Nylon Plastics Parts

>> Professional-Grade Accuracy Electrochemical Breathalyzer for Personal & Professional Use

>> Fiber Grade Pet Bottle Washing &Crushing Line (TL 6000)

>> Hot Selling Plast Foldable Crate Mold Manufacturer Box Plastic Injection Moulding Plastic Tie Mold Maker

>> wholesale PVC fill cooling tower 145mm Cellular Drift Eliminator

>> 7.5m 9m Aluminum Alloy Double Masts Aerial Work Lifting Platform

>> 4.5 mm Copper Bronze Steel Sintered Bushing for Hair Dry Fan Motor

>> NIBOSI Gold Watch Mens Watches Sport Quartz Clock Waterproof Military Wrist Watch 2351 Relogio Masculino Saat Top Brand Luxury

>> Qtj4-40 Hollow Block Moulding Machinery for Nigeria

>> Ditong 108 Colors Professional Waterproof Maquillaje Matte Pearlescent Eye Shadow Performance Stage Makeup Eyeshadow Palette

>> JOHNCOO Carbon Steel 3.5g 5g 7g 10g Fishing Tackle Fishing Round Ball Shape Lead Head Jig Barbed Fishing Hook

>> Good Quality Wholesale Bedding Cushion Home Textile

>> Multi-Nozzle Fog Misting Nozzles Micro Fire Water Mist Nozzle

>> GAPV High Quality various styles Tail Lamp car tail lights for TOYOTA Camry corolla LEXUS LAND CRUISER PRADO Japanese car

>> 1500W UV Curing Lamp for UV Printing Machine

>> Traffic Warning Solar Road Pavement Reflective Road Stud

>> Chicken Cow Manure Rotary Dryer for Sale

>> 2500W 220V Long Life with LiFePO4 Battery Zero Gravity Home Solar Power Station

>> Hot Selling 60/80/168/204/262 Colors Dual Tip Art Drawing Markers, Permanent Alcohol Marker Pen Set with Shoulder Bag