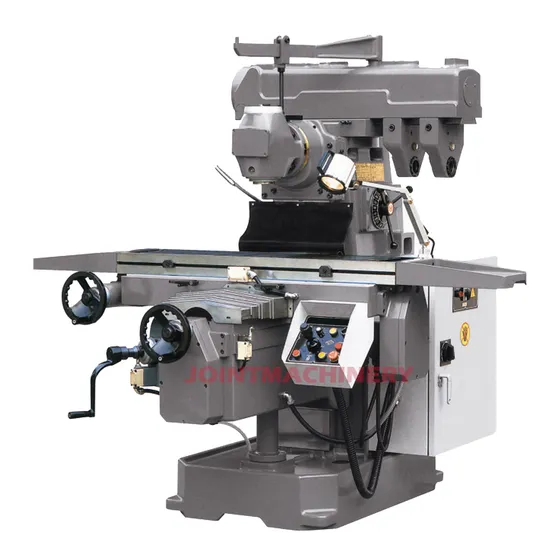

Precision Vertical Horizontal Milling Machine Bevel Milling Machine for Metal Molds

| US$2,000.00-6,000.00 | 1 set (MOQ) |

Basic Info.

Model NO.

4VH

Type

Knee-and-Column Milling Machine

Object

Tool

Structure

Ram

Milling Cutter Type

Vertical Milling Cutter

Milling Cutter Structure

Indexable Type

Controlling Mode

Artificial

Automatic Grade

Manual

Precision

Precision

Certification

CE, ISO 9001

Condition

New

Table Size

1270*254mm

X Axis Travel

900mm

Y Axis Travel

380mm

Z Axis Travel

360mm

Travel of Spindle Quill

127mm

Max Distance From Spindle Nose to Table

440mm

Diameter of Quill

85.725mm

Rotation Speed (Step Speed Milling Head)

50Hz:132-4540rpm; 60Hz:160-5440rpm

Rotation Speed (Variable Speed)

50Hz:40-3125rpm; 60Hz:50-3750rpm

Rotation Speed (Inverter Speed)

0-4200rpm

Spindle Taper

R8/Nt30

Rated Power

3HP

Dimension

1720*1870*1670mm

Net Weight

1500kg

Max Load of Work Table

350kg

Transport Package

Wooden Pallet and Wooden Case

Specification

1720*1870*1670mm

Trademark

JOINT MACHINERY

Origin

China

HS Code

8459590000

Production Capacity

300

Product Description

Recombination Precision Vertical Horizontal Milling Machine

√ Application: Sewing machines, hardware tools, shoe molds, clocks, etc.

√ Suitable for semi-rough and precision processing.

√ Configure high-precision milling heads with wide speed range and high precision level.

√ Optional trapezoidal screw or ball screw, electronic or mechanical power feed or servo motor.

√ Easy to achieve vertical milling, cross milling processing requirements.

√ ±45°, bevel milling.

1. WORKTABLE

Our worktable is the pinnacle of craftsmanship, enhanced with ultra-audio quenching, precision grinding, and meticulously scraped guides for supreme smoothness. Add a rotary table to expand its multi-functional capabilities.

2. TURRET MILLING HEAD

Our advanced turret milling head is engineered to swivel 45° forward-backward and rotate 90° left-right, ensuring versatile milling for complex angles and intricate projects with ease.

3. SPINDLE

Fitted with a high-precision R8/NT30/NT40 spindle, our machine boasts a minimal spindle runout of just 0.003mm, delivering unmatched precision and accuracy.

4. X/Y/Z AUTO FEED

Revolutionize your workflow with our automatic X/Y axis feed and electric Z-axis lift, significantly boosting efficiency and simplifying operations.

5. DRO

Elevate your precision with our adaptable 2-axis or 3-axis DRO, crafted to meet your specific requirements and enhance performance.

Precision Vertical Horizontal Milling Machine Bevel Milling Machine for Metal Molds

| Model | 4VH | |||

| Table size | mm | 1270*254 | ||

| Travel | X axis | mm | 900 | |

| Y axis | mm | 380 | ||

| Z axis | mm | 360 | ||

| Travel of spindle quill | mm | 127 | ||

| Maximum distance from spindle nose to table | mm | 440 | ||

| Diameter of quill | mm | F85.725 | ||

| Spindle | Rotation speed (Step speed milling head) | 50HZ | rpm | 132-4540/(16 grades) |

| 60HZ | rpm | 160-5440/(16 grades) | ||

| Rotation speed (Variable speed milling head) | 50HZ | rpm | 40-3125 | |

| 60HZ | rpm | 50-3750 | ||

| Rotation speed (Inverter speed milling head) | 50HZ | rpm | 0-4200 | |

| 60HZ | rpm | 0-4200 | ||

| Taper | R8/NT30 | |||

| Rated power | HP | 3HP | ||

| Dimension | mm | 1720*1870*1670 | ||

| Weight | kg | 1500 | ||

| Max load of work table | kg | 350 | ||

Shenzhen Joint Machinery Co., Ltd. stands as a globally acclaimed leader, distinguished by our expert manufacturing and export prowess in CNC lathe machines, CNC deep hole drilling machines, and Swiss-type automatic lathes. Our comprehensive selection of top-tier milling and grinding machines underscores our unwavering dedication to delivering first-rate machines and unmatched services worldwide. By integrating cutting-edge Taiwanese and German technologies, our production processes assure superior quality and reliability, upholding the industry's highest standards. Revered for their exceptional performance in precision, stability, and dependability, our machines proficiently tackle a variety of complex machining challenges. Our prestigious products have gained international acclaim, reaching markets across Asia, Europe, South America, North America, and beyond. We are devoted to fostering enduring partnerships with clients globally, consistently creating substantial business value together.

>> Donjoy Hygienic Stainless Steel Twin Screw Pump for High Viscosity Liquid

>> High-Performance Double Needle Cylindrical Sewing Machine with Oil Supply

>> YFMC-720 Updated Design Manual Cold Roll Laminator

>> Queen Size, 1000 Grams Filled Hotel Quality Bedding Bed Pillows

>> aluminum profile cheaper slim frame windows superhouse cheap aluminum windows North American standard aluminum window

>> We67K-300t 5000 CNC Automatic Stainless Steel Bender Machine Hydraulic Sheet Metal Press Brake

>> WiFi+Interlinked Detector De Humo En14604 Ceiling Mounted Wireless Fire Alarm Rookmelder RF Smoke Detector

>> Glass Bottle Cap Metal Bottle Cap Liquor Bottle Topper T Cork Ropp Wooden Bottle Cap

>> MAICTOP car accessories car steering wheel black/beige r for landcruiser 2008-2015 upgrade 2018 fj150 fj200

>> 7z 7blades Pag Blades Axial Cooling Fan for Hovercrafts Heat Dissipation

>> Manufacture orthopedic electrical wheelchair and power wheelchairs

>> Wholesale LED Rainbow Tube Outdoor Engineering PVC Copper Wire Light Rainbow Tube

>> 5% off Chinese Outdoor Road Bike 14 Inch 250W Motor Folding Motorized Motorcycle Electric Pit Bike Scooter

>> OEM aluminum sheet metal 1.5mm spinning lamp housing lampshades

>> Taijia tuf-2000m Modular ultrasonic flowmeter Digital ultrasonic flow meter water flow meter ultrasonic

>> Conference Room Audio System Professional Ceiling Speaker

>> Customized Color Polyamide Plastic Material Virgin Nylon 6 Granules Engineering Resin PA6

>> Industrial Canning Pears Peaches Canned Pineapple Production Lne Canned Fruit Machine

>> Soybean Oil Press Machine Sunflower Oil Press Yzyx140cjgx

>> High Speed Fishing Net Machine Model Zrs22-345X Fro Making HDPE Twisted /Braided Nets

>> Keychain Flashlight with Hook Magnetic LED COB Work Light

>> Ink-Power Premium Compatible Ink Cartridge for Epson Wf-C20600 Printer

>> Top Quality custom boxing hand wraps for Boxing wrist protection Hand bandage 4.5 meter length 5cm width with custom logo

>> Precision Plastic Injection Mold Mould for Household Appliance, Electrical Mosquito Repellent Kg2024110701

>> Rubber Steam Autoclave Industrial/Rubber Vulcanizing Oven Hose Vulcanization Autoclave

>> Offshore Marine Mooring Buoy EVA Foam Buoy

>> 1325 CNC Router Machine for Wood

>> Inficonpsg500 Vacuum Pressure Transmitter Vacuum Gauge

>> Commercial Outdoor Plastic Playground Equipment for Children Amusement Park

>> High Precision Circular Saw Blade Sharpening Gear Grinding Machine for Alloy