Post Consumer Waste Pet Bottle Recycling Washing Machine

| US$25,000.00-300,000.00 | 1 Set (MOQ) |

Basic Info.

Material Processed

Plastic Bottle

Plastic Type

PET

Screw

Double-Screw

Automation

Automation

Computerized

Computerized

Production Name

Pet Bottle Recycling Machine Line

Material

304#Stainless Steel

Thickness of Steel

5mm

Main Motor

Wn Motor

Inverter

ABB

Main Electrical Part

Siemens Schneider

PLC

Siemens

Wanrranty Time

18months

After Sales Service

Engineer Overseas Service

Transport Package

Metal Base

Specification

CE, SGS

Trademark

sino-tech

Origin

China

HS Code

84778000

Production Capacity

100PCS/Year

Product Description

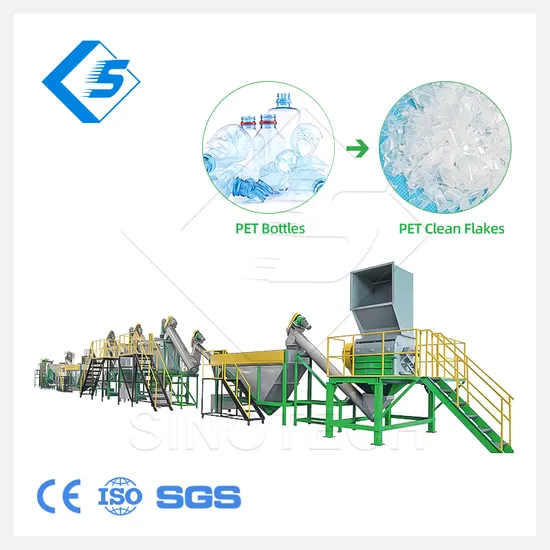

Product DescriptionPlastic PET Bottle Recycling Washing Line

PET bottle washing recycling line is a full automatic crushing washing dewatering and drying production line, it is the ideal equipment to waste mineral water bottles, cola bottle, PET bottle sorting, label removing, crushing, washing, dewatering and drying machines.

Product Description:

1.This line is mainly used for recycling the waste PET bottle, PET container etc.

2. To separate PET bottles to flakes from label, cap, oil, garbage.

3. This line is composed of separator, crusher, cold & hot washing system, dewatering, drying, packing system, etc.

4. Easy to operate, Full automatic.

5. Production capacity: 500KG/H, 1000KG/H, 1500KG/H, 2000KG/H, 3000KG/H

Main Advantage:

1. Automotive line for recycling the PET bottles and other waste plastic profile, except the film.

2. The final product is the cleaning flakes, if you want the final product is pellets, we should equip the granulator line again.

Features:

Capacity: 500-3000kg per hour

Moisture of PET Flakes: Less Than 2%

Cap &Label separate with the PET bottle flakes automatically

Bottle Types: PET Bottle, Plastic Bucket, Water Bottle, Coke Bottle,

Application: PET Strap, PET Yarn Fiber, PET Sheet

Product Parameters

| Model | PET-500 | PET-1000 | PET-1500 | PET-2000 | PET-3000 |

| Capacity | 500kg/h | 1000kg/h | 1500kg/h | 2000kg/h | 3000kg/h |

| Total power | 180kw | 240kw | 350kw | 440kw | 653kw |

| Actual power | 126kw | 168kw | 245kw | 308kw | 457kw |

| Workers | 5-6persons | 7-8persons | 9-10persons | 11-12persons | 14-15persons |

| Water needed | 3-5t/h | 5-6t/h | 6-8t/h | 6-8t/h | 7-10t/h |

| Final production | Water content: ≤1.5% Stacking density: 0.25-0.35 g/m³ Flakes size: 14mm (according to customer request) Fine granule: ≤ 3%; Powder: ≤ 5% | ||||

Detailed Photos

The production line includes: De-baler, belt conveyor, trommel, label remover, sorting table, crusher, floating washing tank, screw feeder, hot washer, high speed friction washing machine, centrifugal dewatering machine, dryer blower and label seperator, silo, electric cabinet etc.

01 Metal chain conveyor

Usage: Cut the bundled PET bottles of wire, through the chain conveyor to the unpacking machine unpacking

02 De-baler

Usage: Manully cut off the packaging steel line of the packaged bottles. then put them into the debaler. The packaged bottles will opened by the running screw blade and run ahead to exit.

03 Trommel

Usage: Separate different impurities such as sand, rocks ,metals, caps according to different size of the holes

04 Label-remover

Usage: for removing the labels by friction between screen and arms

05 Platform of choosing color bottles with metal detector

Usage: Manually separate any impurities that can be seen.

06 Wet crusher

Usage: to crush PET bottles into PET flakes.

07 Floating washing tank

Usage: to remove labels, caps chemicals dirties etc

08 Hot washer

Usage: for wash with hot water and detergent to get rid of oil, dirties and some labels

09 High speed friction washing machine

Usage: through the injection of high pressure water, the effective remova of chemicals and impurities

10 Centrifugal dewatering machine

Usage: to get rid of glue, dirties, oil. detergent and etc.

11 Zig-zag label blower

Usage: to separate labels and dust from the flakes.

productive process

Company Profile

Certifications

Packaging & Shipping

FAQ

Q: How can we get the exact price of plastic machine?

A: Contact us with bottle volume and capacity request. Then we will recommend you suitable model machine soon.

Q: Do you provide any spare parts with machine?

A: Yes, we offer all necessary spare parts together with machine sending and 3 days spare parts delivery after machine sale.(contact us for packing list )

Q: How about your after-sale service?

A: We offer manual instruction and engineer training before loading, after shipment we provide 24 hours online support, video technical support or field installation assist.

Q: What is the lead time?

A: We have standard model machine in stock.It can be delivery within 1 week. If need to make mould, the delivery time need half month after drawing confirmed.

Q: What is the warranty period for your machine?

A: 12 months warranty for components and technical support.

Q: Do you provide custom machines?

A: Most of our machines are customized. Our goal is efficiency and stable performance. We design the machines according to customers products to meet customer' needs.

Q: What's the advantage of SINO-TECH?

A: We provide customers with turnkey projects. Including plant design, blow molding machine and mold installation, debugging, also we can source the auxiliary equipment for customers. We can ship the full set of machines after testing in our factory. It will save a lot of cost and time for customer.

Q: How can we get the exact price of plastic machine?

A: Contact us with bottle volume and capacity request. Then we will recommend you suitable model machine soon.

>> Mini Small Feed Pellet Press Machine with Ce

>> HC-MF053-S3 Industrial Mitsubishi Small Powerful Electric Motors

>> Healthcare Hospital School Education System Homogeneous Vinyl Flooring Rolls

>> Taijia TDS-100H hand held ultrasonic flow meter transit-time Ultrasonic Flow Transmitter Price

>> 4040 reverse osmosis water system FRP glass fiber reinforced plastic pressure vessel

>> Extruder Protein Bars Marzipan Bar Making Machine /Chocolate Energy Bar Production Line

>> 2025 Water Smoke and Charcoal Manufacturing Machine Hot Selling Models Complete

>> Paper Mill Stainless Steel Double Disc Conical Claflin Refiner for Paper Making Stock Preparation Wood Fiber Wood Fiber Chemical Pulp Line

>> Corn Straw Crusher Animal Hay Forage Cutting Machine

>> Real Sheepkin Leather Gloves Manufacturer Custom Women Leather Winter Gloves

>> Farming Equipment Agriculture Tomato Harvest Leaf Picking Cart for Greenhouse

>> Heavy Duty Tail Wheel Hub for Rotary Cutter

>> Industrial Powerful Animal Chicken Cattle Cow Poultry Feed Processing Machine Livestock Fish Shrimp Pet Poultry Feed Process Machine

>> Hot dipped galvanized farm barbed wire length price per roll

>> ISO 13485 Turnkey Service Medical Assembled PCBA

>> Asia FUJI Escalator Low Cost Resedential Home Commerical Escalator for Sale

>> China Cheap Peeling Machine for Steel Round Bar

>> Agricultural Farm Cultivators 178f Diesel Powered Tiller (DT900)

>> Mobile tromel gold washing equipment gold trommel screening price

>> High Efficiency 150W UFO LED High Bay Light for Warehouses

>> Dead Animal Carcasses Professional Processor Poultry Pet Single Shaft Shredder

>> Multiple Colour Waterproof U Shaped Life Buoy with Warm Service

>> Denim Shoddy Garment Leftover Fabric Hard Waste Recycling Machine

>> for Mercedes SL R230 modified Black series FRP wide body kit

>> 9500lbs Electric Winch for Truck/Trailer/Jeep

>> Computer Direct Drive Thick Material Synchronous Belt Knife Flat Industrial Sewing Machine

>> Large Scale Outdoor Artificial Glass Fiber Artificial Palm Tree Landscape

>> CE Round Hay Baler Mini Large Small Square Grass Silage Straw Packing Machine Baling Press Rectangular Farm Agricultural Tractor Power Tiller 9yk870 Machinery

>> Feed Pharmace Hammer of Feed Mill Screen

>> Oxford cloth Tool Pocket Pouch Belt Small Pocket Tool bag Professional Waist Work pouch for Electrician