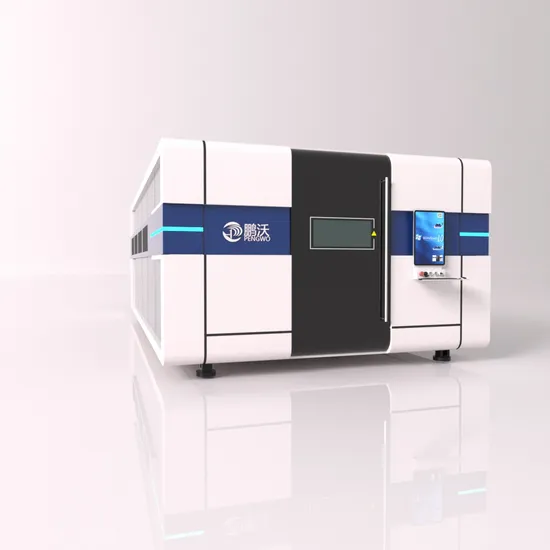

Efficient Fully Enclosed Exchange Platform Laser Cutting Machine for Heavy Duty

Basic Info.

Model NO.

G1530F-C 2000W

Application

Home Appliance, Environmental Equipment, Petroleum Machinery Manufacturing, Agriculture Machinery, Textile Machinery, Food Machinery, Aerospace Industry, Automotive Industry, Shoemaking Industry, Woodwork Industry, Advertising Industry, Aerospace

Cooling System

Water Cooling

Technical Class

Continuous Wave Laser

Applicable Material

Metal

Structure Type

Gantry Type

Laser Classification

Solid Laser

Laser Technology

Laser Control Fault Cutting

Power

1500W-30000W

Cutting Thickness

0.5mm-80mm

Appearance Material

Metal Shell Material

Customized

Yes

CNC or Not

CNC

System

Optional

Transport Package

Wrapping Film and Plastic Soft Bag

Specification

8300*2850*2225

Trademark

PENGWO

Origin

Shandong, China

HS Code

8456110090

Production Capacity

5000pieces/Year

Product Description

Product Description1. Crafted with precision, this machine boasts a high-rigidity bed featuring an exclusive high-temperature CNC electric furnace standard annealing process. This meticulous annealing treatment ensures the machine tool maintains its accuracy over the long haul.

2. The innovative side design allows the machine tool to slide open, facilitating effortless man-machine interaction, optimizing accessibility, and conserving valuable space.

3. Equipped with a state-of-the-art fiber laser, this machine achieves a remarkable electro-optical conversion rate with a 30% conversion efficiency. This means substantial power savings during operation, culminating in exceptionally low operating costs.

4. Featuring an automatic exchange platform, this machine minimizes downtime by swiftly reducing the waiting period during loading and unloading processes, thus significantly enhancing operational efficiency.

5. Experience unparalleled cutting edge quality where each cut is smooth, flat, and exhibits minimal deformation, ensuring superior results.

6. With its rapid cutting speed and dramatically low operating costs, this machine promises a swift return on investment, making it an economically savvy choice. Detailed Photos

RAYTOOLS Laser Head: A pinnacle of precision engineering, delivering unparalleled cutting accuracy for even the most complex designs.

Auto-focus Laser Head: Offers seamless and dynamic focusing, ensuring the perfect cut every time without manual adjustments.

Strong and Curable: Built to withstand demanding conditions while maintaining peak efficiency through rigorous use.

Accurate and Rapid: Experience precision like never before, combined with speed that meets the demands of high-volume production.

Long Service Life: Durability redefined, designed for extended use with minimal maintenance, providing exceptional value over time.

CYPCUT Control System: Intuitive and powerful, ensuring effortless operation with advanced capabilities at your fingertips.

Easy to Use: User-friendly interface allows for smooth operation and quick mastery, even for beginners.

Various File Editing Functions: Versatile editing features cater to a wide range of design needs, ensuring flexibility and creativity.

Support Remote Control: Stay connected and in command from anywhere, with seamless remote operation capabilities.

Real-time Alarm and Protection: Stay secure with instant alerts and safeguarding protocols that ensure uninterrupted operation.

DELTA Servo Motor: A powerhouse of precision and reliability, driving your machine to new levels of accuracy and performance.

High Accuracy: Achieve perfection with every cut, thanks to unmatched precision engineering and technology.

High-speed Performance: Elevate your productivity with lightning-fast operation that doesn't compromise on quality.

High Adaptability & Stability: Tailored for diverse environments, offering consistent performance and unwavering stability.

Timeliness, Short Dynamic Response Time of Motor: Experience efficiency with minimal delay, ensuring swift motor reactions for fast-paced demands.

Taiwan Guide Rail: Engineered for smooth and silent operation, ensuring quieter work environments and superior performance.

Lower Noise: Designed for peace, allowing operations to proceed with reduced sound pollution for a calmer workspace.

Wear-resistant: Crafted with longevity in mind, resisting wear to maintain high performance over extensive use.

Smoothly, Enable Fast Speed: Glide through projects effortlessly, with smooth operation that supports accelerated workflow.

Products pictures

Product Parameters

| Name&Model | Laser Cutting Machine G1530F-C |

| Working Area | 1500mm*3000mm |

| Laser Power | 1500W/2000W/3000W/6000W |

| Machine Structure | Stable & strong welded bed with high temperature annealing |

| Beam | Aviation aluminum/Integrated cast aluminum beam |

| Applicable Material | Carbon Steel Stainless Steel Etc( Metal Laser Cutting Machine ) |

| Laser Source Brand | MAX/RAYCUS |

| Key Selling Points | Automatic |

| Warranty | 2 years |

| Condition | New |

| Moving Speed | 120m/min |

| X axis travel (mm) | 1530 |

| Y axis travel (mm) | 4030 |

| Z axis travel (mm) | 80 |

| Max acceleration | 0.8G |

| Position Accuracy | ±0.03mm |

| Repositioning Accuracy | ±0.02mm |

| Computer | Industry Computer |

| Transfer method | Gear rack dual drive |

| Working Voltage | 380V,3phase,50hz/60hz(customized) |

| Dimension | 8300*2850*2225 |

| Graphic Format Supported | AI, PLT, DXF, BMP, DST DWG, LAS, DXP |

| Machinery Test Report | Provided |

| Video outgoing-inspection | Provided |

| Applicable Material | Metal Steel Carbon Copper |

Company Profile

Nestled in the vibrant city of Dezhou within Shandong Province, Shandong Pengwo Laser Technology Co., Ltd. was established in 2005 and has rapidly evolved into a prestigious entity within the realm of laser technology. Specializing in the research, development, and manufacturing of advanced laser processing equipment, we pride ourselves on delivering cutting-edge intelligent manufacturing solutions tailored to our clients' needs. With years of continuous development and a wealth of technological expertise, we stand as a leading force in China's laser application equipment sector. Our expansive operations are housed across two state-of-the-art production bases in Tianquxin District and Pingyuan County, collectively spanning over 80,000 square meters.

Our portfolio boasts a diverse array of laser processing equipment, including medium and high-power laser cutting systems, precision laser welding apparatus, sophisticated laser cladding solutions, and an extensive range of other laser-driven technologies.

Installation Instructions

At Shandong Pengwo Laser Technology Co., Ltd., the production journey of our Efficient 30000W Fully Enclosed Laser Cutting Machine for Heavy Duty is a testament to superior craftsmanship. From the initial welding stages to the meticulous installation and commissioning, our seasoned engineers and master technicians bring unparalleled expertise in laser cutting technology. Their adeptness ensures precise setting of cutting parameters, delivering exceptional cutting accuracy and impeccable surface quality. Our state-of-the-art computer numerical control is endorsed by a leading brand renowned across China for its excellence. One standout component of this 'gantry milling' machine is the '360-degree fully automatic side milling surface,' a feature that performs comprehensive 360° side milling. This not only elevates the aesthetic appeal but also significantly extends the quality and service life of the machine. Throughout the assembly, cutting-edge precision tools such as the 'precision instrument' and 'dial indicator' are employed in a rigorous three-time measurement process to uphold unparalleled machine accuracy.

After Sales Service

Installation Training (3 Premium Options):

A. Benefit from comprehensive installation, operation, maintenance, and troubleshooting guidance with our detailed training videos and user manuals provided in English. In addition, enjoy seamless technical support through email, fax, phone, Messenger, or WhatsApp to assist with any installation, usage, or adjustment inquiries.

B. Experience firsthand training in China with our expert team. We ensure a comfortable stay by providing accommodation throughout your training period.

C. Leverage our strong and proficient after-sales service team in China. With engineers fluent in English, we ensure effective communication and rapid problem resolution. For your convenience, flight arrangements can be made to facilitate this process.

Training Duration: A recommended 3-7 working days for optimal experience:

Enjoy complimentary services for installation, commissioning, and training (covering maintenance and operation) directly at your personal work site, provided by the supplier. The costs for the supplier's round-trip airfare, food, accommodation, local transport, translation services, internet, communication, and visa at the Buyer's location will be covered by the Customer, following documentation of actual expenses.

FAQ

Q1. When was your factory established?

We have been specialized in the R&D, manufacturing and intelligent manufacturing solutions of laser processing equipment since 2005, mainly focusing on laser processing equipment such as fiber laser cutting, laser welding equipment, laser cladding equipment, etc.

Q2. What should I do if there is a problem with this machine during the warranty period?

The quality assurance period is 12 months from the date the goods arrive at the destination port. Except for man-made damage, we are responsible for providing accessories free of charge during the warranty period. After the quality assurance period, if you need to repair or replace parts, you must pay.

Q3. How to install and use?

We will provide training videos and English user manuals for installation, operation, maintenance and troubleshooting for the machine. When you encounter installation, use or adjustment problems, we will provide technical guidance by email, fax, telephone/Messenger/WhatsApp, etc.

Q4. What should I do if there is an after-sales problem?

You can directly describe your problem to the after-sales staff. China's strong after-sales service team. Our engineers (employees) can communicate and solve problems in English, and can be arranged once a day per person when you need it. If I need to go to your place to help, I will quickly arrange to go there and quickly fly to help you.

Q5. How about wholesale price?

If you are a wholesaler, distributor or agent, please contact us to get wholesale price.

>> SHENGKE 2021 New Arrival Women Watch Young Hand WatchFor Girl Quartz Handwatch Minimalism Feminine Wrist Watch K0084L

>> 50-300L Dual Shaft Paddle Type Laboratory Powder Mixer

>> 8.5"Series Glass Breaker Outdoor Emergency Rescue Pocket Knife

>> 100% Working Good Screen for Vodafone Vf795 LCD Display with Competitive Price

>> Reaction Kettle ASME Available Longqiang Mixer Chemical Reactor Seeds Tank with Factory Price

>> New Wedding Props Luminous Transparent Water Drop Modeling Wedding Chandelier Hotel Stage Venue Decoration Lamps and Lanterns

>> disposable barbecue mesh expanded metal grill grate Online shopping India

>> Labour Saved Press Machine for Metal Fine Machining Factory

>> Plastic Wood Floor 4mm Vinyl Planks Luxury Spc Flooring

>> Modern black painting kitchen cabinet design photo

>> Zyfire 10bar Durable 4 Inch Rubber Covered Irrigation Hose Pipe for Agriculture

>> Aluminum Black Frame Iron Art Decoration Tent Wedding Events Tent

>> Agricultural Cultivation Machinery Driven Disc Harrow for Sale

>> Hot-Selling Hot-DIP Galvanized Steel Pipe Farm Machinery Livestock Equipment Cow Stall

>> Adjustable Preset Torque Wrench Brushless Handheld Electric Screw Driver Wrench

>> Good Price High Accuracy Efficiency Sg450 Saw Blade Sharpening Machine

>> Cow Dairy Farm Use Cow Foot Washing Basin Livestock Bath Paddle

>> F8 Medium Efficiency Multi-Layer Non-Woven Fabric Air Pocket Filter

>> QUEEN Hot Selling Nine Ball QUEEN Billiards Table with Solid Wood for Indoor Games

>> Mould Maker Custom Plastic Moulded Automotive Lamp Housing Tooling Injection Moulding Auto Headlights Len Cover Parts Mold

>> 27W-115W LED Street Light Corn Bulb Light E27/E40

>> Outdoor Camping Lightweight Sun Shade Waterproof Tent Canopy Beach Shelter Sun Shade Tent For Fishing

>> Zinc Galvanizing Large Grey Iron Metal Fabrication Sand Casting Services

>> Economic Portable Outdoor Camping Canvas Picnic Blanket Camping Picnic Mat Mattress

>> Amazon Hot Velvet Flocked Clothes Hangers in Black/White/Grey/Pink/Blue Made of Non-Slip Flocking Plastic for Adult/Kid Shirt&Coat Clothing

>> New Arrivals 2000W Laser Cleaner Portable Wood Rust Car Painting Laser Cleaning

>> Auto Timing Chain Kit for Toyota Yaris Verso 1.3 OEM 1356121040 1350621040 TK1408-5

>> Plastic Film Shredder Machine

>> Adhesive Packing Aluminum Collapsible Tubes for Super Glue

>> Electric Laboratory Printing Machine