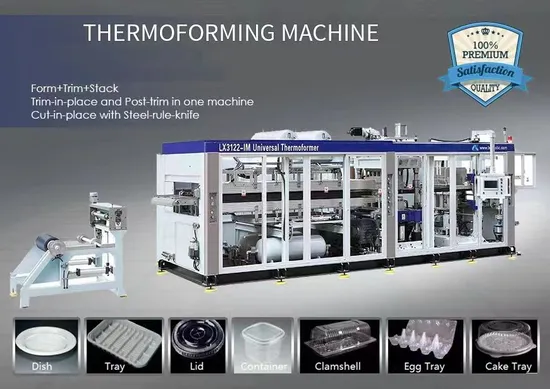

Multi Function Plastic Tray Egg Tray Food Container Plate Vacuum Flower Pot Thermoforming Forming Machine for PP PS Pet Material

| US$89,000.00-138,000.00 | 1 Piece (MOQ) |

Basic Info.

Model NO.

LX3122HF-IM-C202

Molding Method

Pressing

Automatic Grade

Automatic

Forming Area

800mm*600mm Max./750*400mm Max.

Forming Depth

120mm Max. /180mmmax.

Dry Run Speed

40cycles/Min Max.

Film Thickness

0.2-2mm

Sheet Width

800mm Max.

Suitable Material

PP PS Pet PVC BOPS

Air Pressure

0.7MPa

Production Range

Container, Clamshell ,Tray and Lid

Automaticity

Forming, Cutting, Stacking and Conveying

Cooling Water Consumption

13 Liters/Min 15° - 20°c

Transport Package

Plastic Film with Anti-Rust Oil

Specification

1200*2600*2500mm

Trademark

LXPLASTICS

Origin

China

HS Code

8477409000

Production Capacity

20sets/Year

Product Description

BRIEFHF-IM thermoforming equipment is a trim-in-place type thermoforming machine which takes advantage of mould with rules steel knife for performing forming and cutting in the same station. and the second and the third cut-station are available for performing fuction of post-trim and hole-punch.

it is perfect for making part of PP PET PS etc and completely automatically produces disposable rectangular or square or round shaped roll-edged containers and trays with forming, trimming, and stacking conveying on one operation cycle.

Design Featurethermoforming equipment Use Steel-Rule-knife for performing forming and cutting in the same station

Trim-in-place for processing PP PET PS PVC BOPS material etc. specially perfect for PP .

Second cut-press and Third cut-press are available for hole punching and post-trim

Automatic stacking ,counting unit and conveying system

Trim-in-place for parts with rolled edge (turn-down lip)

Technology of trim-in-place brings a neat and identical trimming(cutting)

Plug assistant for deep forming of draw

Floating knife and free knife are available for post-trimming film with high shrinkage rate.

Extra Contact Heat plate for Minimizing power consumption is available.

| Specification | LX3122IM |

| Mould Area | 800*600mm Max |

| Depth of Draw under sheet | 120 mm Max |

| Depth of Draw above sheet | 30mm Max/120mm Max |

| Clamping force | 750KN |

| The Second Cut-Press | Available |

| The third Cut-Press | Available |

| Suitable material | PP PET PS PVC BOPS |

| Sheet Width | 460- 850 mm |

| Material Thickness Range | 0.2-1.5mm |

| Material Roll Diameter | 1000 Max |

| Dry run Speed | 45cycles/min Max. |

| Power Supply | 3-N AC380V±15V ,(others at request) |

| Power Consumption | Approx.35kilowatts/hr |

| Air Pressure | 0.7Mpa |

| Air Consumption | 2500 Liters/min |

| Cooling Water Consumption | 13 Liters/min 15° - 20°C |

| Dimensions | 9.5m*2.2m*2.2(L*W*H) |

| Trim-in-place IM-2in1 |

| Trim-in-place with second cut-press IM-3in1 (optional) |

| Trim-in-place with second cut-press and third cut-press IM-4in1 (optional) |

| Service |

>> Break Glass Key Guard with CE (ES-9002-3)

>> Qingdao Small Manual Curve Edge Banding Machine for Sale

>> Luxury Waterjet Marble Medallion Design Sale

>> Automatic 12 Head 12 Needles Twin Siqvance Machine Garment Hat T-Shirt Embroidery Brother Invocid Ez Frames Machine Embroidery

>> OEM CNC Machining Aluminum CNC Turned Parts Turned Components

>> 2m Custom Printed Zollstock Folding Ruler Meter Sticks

>> Tiancheng International Trading (Liangshan) Co., Ltd. Boutique Wushiling Concrete Pump Truck 46 Meters Concrete Pump Truck

>> Heavy-Duty 63-Ton CNC Bending Processor for Metal Sheet Plates Stainless Steel

>> Waste Paper Forming Egg Dishes Forming Machinery China

>> Farmland Tillage Machinery Rotary Tiller Working Width 250cm

>> Fuel Dispenser with LED Light Logo Petrol Pump Machine

>> High Tenacity Fishing Nylon and Polyester and PP Twine Net Twine - Sturdy Nylon and Polyester Thread, High-Quality Raw White and Various Colors, 210d/2ply.

>> Paint colors white American style toilet bedroom bathroom glass interior contracted wooden wood interior doors designs

>> IO coupler Standard plc slave Modbus adapter OpenPCS programming environment IEC 61131-3 compliant IO coupler plc slave

>> Mosquito Liquid Heater Cartoon Design Refill Vaporizer Diffuser Bluetooth

>> CNC Drilling Sawing Machine Line for Steel Beam Pipe Steel Structure Tube Plate Peb Profiles Beam Drilling Milling Machine

>> Haifu Machinery Weaving Machine Cost-Effective Water Jet Loom

>> Horizontal Mixing Machine High Quality Chicken Waste Horizontal Fertilizer Mixer Machine

>> Wholesale Modern 6 Chairs Kitchen Restaurant Dining Room Furniture Square Mesa Black Dining Table

>> Factory Customized High Precision Mould Product Hinge Automatic Mold Manufacturing Flag Hinge Automatic Mould

>> Sublimated Baseball Jersey Customized Leisure Wear.

>> Aluminum Custom Printed Folding Designed Display Event Pop up Canopy Tent Waterproof Event Canopy Gazebo Marquee Trade Show Tent

>> Efficient Helical Bevel Planetary Gearbox Solution for High Torque for Concrete Mixing

>> Fr4 Fiberglass Sheet Insulation Material

>> 2 in 1 Metal USB 3.0 Flash Drive High Speed Portable Mobile Phone USB Drive for Print Logo

>> Timing Chain Kit TK1004-14 with oe no.0615054 0615418 for OPEL Chevrolet Z22SE 2.2L Z20NET 2.0L

>> Waterproof Customized Logo Bicycle Insulated Thermal Food Delivery Bag

>> Wet Gas Meter 1L/H~300L/H

>> Taijia BM-III British Pendulum Skid Resistance Tester With Rubber Slider for sale

>> Cheap Pirce Broiler Floor Raising Chicken Farming/Farm Feeding System Automatic Poultry Machine/Equipment