Fully Automatic PLC Control Concrete Block Machine for Efficient Production

| US$20,000.00-5,000,000.00 | 1 Set (MOQ) |

Basic Info.

Model NO.

SLST1400

Certification

CE, ISO

Customized

Non-Customized

Automatic Grade

Automatic

Type

Vibration Molding

Color

White/Blue

Control Mode

Full Automatic PLC Control

Pallet Size

1400*950mm

Max.Molding Area

1310*900mm

Working Pressure

5-25MPa

Overall Dimensions

7150X3050X4025mm

Transport Package

International Standard Packing

Specification

7150*3050*4025mm

Trademark

S. L MACHINERY

Origin

Quanzhou, Fujian

Production Capacity

500sets/Year

Product Description

Product DescriptionSLST1400 Fully Automatic Servo Brick Machine

Experience the pinnacle of innovation with our fully automatic servo wall and floor brick production line. Utilizing state-of-the-art servo vibration and hydraulic technology, this system can be customized with advanced features like lateral shifting, core pulling, EPS board conveying, and rapid mould switching to perfectly align with your production needs. It adeptly supports a wide array of standard concrete products including curbstones, hollow bricks, PC imitation stone bricks, solid bricks, and water slope protection bricks.

1. Elevate your production capabilities with an impressive 20% boost in efficiency.

2. Witness a remarkable 15% reduction in energy consumption, optimizing your operational costs.

3. Benefit from a significant 10% decrease in noise levels, creating a more peaceful work environment.

Technical Parameters - Unleash the full potential of your production capabilities with meticulously engineered specifications.

| Model | SLST2000 | SLST1500 | SLST1400 | SLST1300 | SLST1000 |

| Pallet Size(mm) | 1400x1350 | 1400x1200 | 1400x950 | 1400x750 | 1220x900 |

| Max.Molding Area(mm) | 1310x1300 | 1310x1150 | 1310x900 | 1310x700 | 1100x860 |

| Min.Product Height(mm) | 45 | 45 | 45 | 45 | 45 |

| Max.Product Height(mm) | 500 | 500 | 500 | 500 | 350 |

| Cycle Time(s) | Solid Brick 12-15 Paver 12-25 | Solid Brick 12-15 Paver 12-25 | Solid Brick 12-15 Paver 12-25 | Solid Brick 12-15 Paver 12-25 | Solid Brick 12-15 Paver 12-25 |

| lf the required pallet size or product heights are not listed here, we are happy to make special plans for you. | |||||

Production Table - Transform your production process with our comprehensive and adaptable production table.

| Model | Brick Size | Production(Per mould) | Production(8h one shift) |

| SLST2000 | Hollow Brick 390x190x190mm | 18 | ≈34,500Pcs 480m³ |

| Solid Brick 240x115x53mm | 105 | ≈252,000Pcs 368m³ | |

| Paver 200x100x60mm | 66 | ≈95,000Pcs 1900m² | |

| SLST1500 | Hollow Brick 390x190x190mm | 15 | ≈28,000Pcs 394m³ |

| Solid Brick 240x115x53mm | 94 | ≈225,600Pcs 330m³ | |

| Paver 200x100x60/80mm | 60 | ≈86,000Pcs 1700m² | |

| SLST1400 | Hollow Brick 390x190x190mm | 12 | ≈22,400Pcs 315m³ |

| Solid Brick 240x115x53mm | 73 | ≈175,200Pcs 256m³ | |

| Paver 200x100x60/80mm | 48 | ≈68,800Pcs 1350m² | |

SLST1300 | Hollow Brick 390x190x190mm | 9 | ≈17,200Pcs 240m³ |

| Solid Brick 240x115x53mm | 55 | ≈132,000Pcs 193m³ | |

| Paver 200x100x60mm | 36 | ≈51,800Pcs 1030m² | |

| SLST1000 | Hollow Brick 390x190x190mm | 10 | ≈18,600Pcs 262m³ |

| Solid Brick 240x115x53mm | 62 | ≈148,000Pcs 216m³ | |

| Paver 200x100x60/80mm | 40 | ≈57,300Pcs 1130m² | |

| Difference between different raw material and ratio If a cuber is required,the capacity may be affected | |||

We accommodate an array of common materials and can also incorporate alternative materials to suit your specific requirements, as illustrated in the following picture.

Detailed Photos

System Function - A seamless integration of advanced systems designed to enhance operational performance.

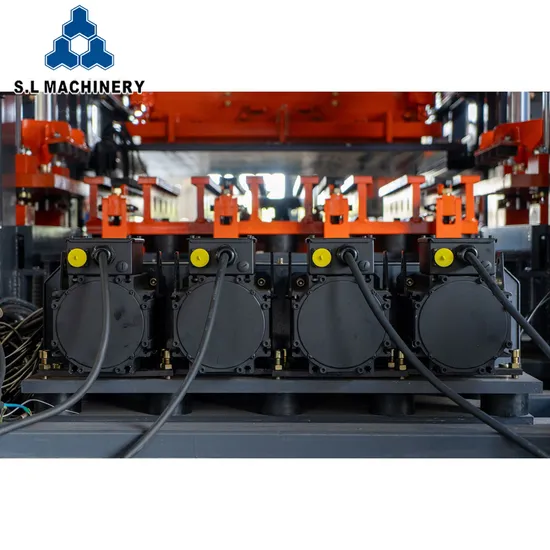

Servo Vibration System and - Unlock superior product quality and consistency with our advanced servo vibration system. Servo Control System - Achieve unparalleled precision and control with our innovative servo control technology.

Efficient Servo Hydraulic System and - Experience optimal efficiency with our cutting-edge servo hydraulic system. Quick Mould Changing - Maximize productivity with our rapid mould changing feature, minimizing downtime.

Mould Box Damping Airbag and Mould Head Shifting Device - Enhance production efficiency and product quality with our specialized mould handling systems.

PLC Controller - Simplify operations with our user-friendly PLC controller, ensuring seamless process management.

Project Cases - Discover real-world applications and success stories that highlight the versatility and efficiency of our machinery in various projects.

Brick Example

FAQ

Q1: Do you offer warranty on your equipment?

A1: Yes, we offer a full warranty on new equipment purchasing.

Q2: which payment terms you can do?

A2: We can work on T/T term, L/C term and T/T & L/C term:

T/T term: 30%T/T as deposit, the remainder 70% should be paid before shipment.

L/C term: 100% by irrevocable L/C at sight without "soft clauses"

T/T & L/C term: 30% T/T as deposit, the balance 100% by irrevocable L/C at sight without "soft clauses"

Q3: Where is the port of loading?

A3: Normally the port of loading is XIAMEN PORT, FUJIAN, CHINA; also it can be the main port of CHINA MAINLAND

Q4: How about the installation and commissioning on new purchases?

A4: We will send our technicians to your place to guide the installation, commissioning and training your operator. You should pay for board(meals), lodging expenses and a daily allowance of USD$200 per person per day for our service engineer ; prepare the tools (crane, welding machine and electric wrench), the power and the materials for testing work; do the foundation work before our technician arrive your work site.

Q5: How much space is necessary for brick machine, wall panel machine and concrete batching plant?

A5: Normally, a brick factory needs at least 3000m2 of land, wall panel factory needs 6000m2 land, concrete batching plant requires 3000m2 of land; the land area includes raw materials stacking, equipment area, office space, vehicle access , finished products area and so on.

Q6: The durability of the block making machine?

A6: The main steel structure equipped with Q235 heavy duty steel, it's durable.

The mould frame is made of 16 Mn steel, the press board made by 1045 heavy duty steel, can press more than 100,000 times.

Equipped with Panasonic PLC and frequency transformer; SIEMENS electric element.

Equipped witorthman hh Nydraulic pump and valves.

Under regular operation, our machines can running more than 20 years, while it depend on the daily maintenance.

In Algeria, Brazil, Egypt and Saudi Arabia, S.L MACHINERY 2nd hand block making machine are popular, so after you finish the project, you can sell it as 2nd hand machine.

Q7: How long will the delivery time take?

A7: Normally it will take about 35-40 days to produce the ordered machines. Most of the time, we can have an immediate delivery of our regular machines in 30 days.

Q8: Can I visit your factory?

A8: Of course. We warmly welcome you to visit our factory. And we provide you great services like airport pick up, hotel booking, etc.

Q9: What is your technological advantage of block machine?

A9: 1. Frequency Conversional Motor Automatic Vibration System ;

2. SIEMENS PLC System

3. Oil Cylinder Synchronously Demoulding

4. Noise & Aftershock Reduction System

5. More Homogeneous and Faster Mixture Discharging

6. Full servo production line with high efficiency and energy saving(Optional)

7. Remote monitoring equipment, timely provision of equipment failure warning

Q10: What is your warranty?

A10: We are responsible for all the repairs that caused by our quality problems within one year's warranty. Foreign accessories are generally delivered by DHL in orde to provide service for foreign customers promptly.

Q11: If the warranty expired, will you continuely to provide us after-sale service?

A11: The customers whose products have passsed its warranty date are entitled to enjoy our after-sales service for life.

Q12: What Raw Materials can be used for making blocks and bricks ?

A12: Cement, Sand, Fly ash, Coal residue, Coal wastes, Sand, Crushed Stone ,Construction wastes ,etc.

Q13: This machine can make different types and designs of blocks & bricks?

A13: Yes, the same machine can make different types and designs of hollow blocks , solid bricks, color pavers, curbstone etc. it only need change different moulds accordingly.

Q14: What is your company advantage?

A14: Our compnay has more than 30 years experience in the the field of block machine. We can not only offer you the machine but aslo the comprehensive service, one-station service.

Q15: How many countries have you sold to?

A15: Our machine has been exported to more than 102 countries and regions, up to 10,0000 users

>> Organic fertilizer disc granulator, compound fertilizer granulation equipment, multifunctional animal manure granulator machine

>> 95ppi, 350G/M2, 1.6mm, Porous Metal Foam Nickel for Ni-MH Battery

>> Wholeasale 6 Panel Embroidery Snapback Cap Mesh Baseball Cap Cotton Baseball Cap

>> Disposable Food Container Packaging Box Biodegradable Paper/Packing/Storage/Packaging/Lunch Box Making Machine

>> Jimbo china heavy duty counting cash depository coin drop slot safes

>> Pile Integrity Test Equipment Sonic Integrity Test hot sale

>> 24W 36W 72W High Brightness Ucs1912 Full Color Pixel LED Wall Washer IP65

>> Portable X ray Baggage Scanner SPX3025P Security Screening X-ray Detector

>> SHXJ1500 integrated type CNC wire saw shaping stone cutting machine with ce certificate

>> Perforated Filter Tubes Manufactured Square Holes Perforated Cartridge

>> Taijia concrete rebar scanner profoscope rebar detector locator cover meter concrete rebar scanner

>> Spunlace Nonwoven Fabric High Quality Parallel and Cross Nonwoven for Wet Wipes

>> 200d UHMWPE Fiber for Gloves (TYZ-TM32-200D)

>> Siemens System China Manufacturer Deep Hole CNC Horizontal Honing Machine Used on Hydraulic Cylinder Block Tube Honing Grinding

>> Foshan CS Carbon Stainless Steel Iron Welded Round Tube Pipe Production Line Pipe Making Machinery

>> Ultrasonic Guard Giant 1555 Airplane Water Sports Housing Shaft Briquette Machine Boat Propeller

>> Plastic Films and Bags High Speed Mixer

>> Low Carbon Steel Aluminum Stainless Steel Punching Hole Decorative Perforated Metal Mesh Sheet Plate for Fencing

>> 500ml Strawberry Aloe Vera Drink

>> 2024 Newest Commercial Treadmill with 21.5′′ Touch Screen

>> Export Europe and The United States Can DIY Window Screen Support ODM/OEM

>> 620mm Width Leather Sewing Machine Leather Machinery Belt Skiving Machine

>> Tianlai Tl-2650 Custom High Quality Large 300W Speakers Double Wall Mounted Home Theater System

>> Hot-selling 5 Newton Meter / Force Gauge Spring Dynamometer Balance Physics Experiments

>> Radial Arm Drilling Machine Metalworking High Precision CNC Heavy Metal Drilling Radial Drilling Machine

>> Hot selling high-quality 8-inch 8080 8040 FRP container membrane housing

>> Chinese PVC Resin Raw Material Sg3 Sg5 Sg8

>> High quality carbon powder pellet making machine/coal briquette machine

>> High Quality and Durable Rubber Roll Sports Floor Mat Production Machine

>> Automatic Rubber Vulcanizing Press Machine, Frame Hydraulic Vulcanizer/Curing Press, Column Floor Mat Tiles Molding Press