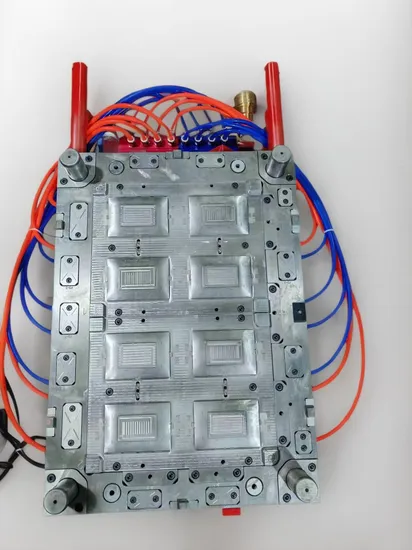

Plastic Parts Mold for Wall Switch 05

| US$6,000.00-20,000.00 | 1 Piece (MOQ) |

Basic Info.

Model NO.

KGMJ00012

Surface Finish Process

Matte

Mould Cavity

Multi Cavity

Plastic Material

PC

Process Combination Type

Single-Process Mode

Application

Car, Household Appliances, Home Use, Car, Household Appliances

Runner

Cold Runner

Design Software

UG

Installation

Mobile

Certification

ISO

Standard

HASCO

Customized

Customized

After-sales Service

10 Years, 1 Year

Transport Package

Wooden Box

Specification

steel

Trademark

KG trademark or your private trademark

Origin

Wenzhou, Zhejiang, China

HS Code

848071

Production Capacity

5000 Piece

Packaging & Delivery

Package Size

100.00cm * 100.00cm * 100.00cm

Package Gross Weight

2000.000kg

Product Description

Product Description| Product Description | ODM plastic injection molding |

| Plastic Materials: | PS, ABS, PP, PVC, PMMA, PBT, PC, POM, PA66, PA6, PBT+GF, PC/ABS, PEEK, HDPE, TPU, PET, PPO,...etc. |

| Standard: | ISO9001 |

| Other materials: | Rubber, Slilconce rubber, LSR,Aluminum, Zinc,Copper...Metal...etc. |

| Feature: | Precision |

| Size: | According to your 2D, 3D Drawing |

| Color,Quantity,Unit price,Tooling cost,Tooling size: | To be discussed |

| Package: | Standard exported Wooden box packed |

| Mold Building Lead Time: | T1, 40-50 Working days, Part measurement report (upon required). |

| Export Country: | Latin america, North America, Europe, Japan, Australian, UK, Canada, etc. |

| Experience: | 16 years experience in plastic injection mold making and plastic prouducts produce. |

| To be discussed | In-Mold Decoration, Injection Mould, Plastic Mold, Overmould, 2K Mould, Die-Casting Mould, Thermoset Mold, Stack Mold, Interchangeable Mold,Collapsible Core Mold, Die Sets, Compression Mold, Cold Runner System LSR Mold,...etc. |

| Mould Base Material: | Per Customer's Requirment. |

| Surface Finish: | Matte, polishing and other requirement based on customer |

| Cavity/Core Steel: | Multi Cavity |

| Hot/ Cold Runner | Cold Runner |

| Mould Life: | 500000 Shots. (According to your working environment.) |

| Design & Program Softwares: | CAD, CAM, CAE, Pro-E, UG, Soild works, Moldflow, CATIA....etc. |

| Equipments: | High speed CNC, Standard CNC, EDM, Wire Cutting, WEDM, Grinder, Plastic Injection Molding Machine for trial out mold from 50-3000T available. |

How to order

Company Profile

Wenzhou KoGo Precision Mould Co., Ltd. was established in 2006 and headquartered in Wenzhou,Zhejiang. In an industry that demands precision, Wenzhou KoGo Precision Mould Co., Ltd. has earned a reputation for uncompromising excellence and accuracy. Wenzhou KoGo Precision Mould Co., Ltd. has advanced management concepts and complete processing equipment, we are a one-stop service company gathering research, development, design, manufacture, Processing and technical training. So that we have rich successful experience in making all kinds of mould according to your requirement. We can offer your ODM/OEM service, mould design. Even if production design base on your demand. As you know, there is a professional engineer team that will bring you high precision standard mould with the parts, it also can save your cost and time.

FAQ

Q: What services do you provide?

A: We manufacture plastic injection molds and produce plastic injection parts for sampling and bulk production.We also provide mold design services.

Q: How can I contact you?

A: You can send us an inquiry via email, Made in China TradeManager, WhatsApp or Wechat. We will reply to you within 24 hours.

Q: How can I get a quotation? A:After receving your RFQ, we will reply to you within 2 hours. In your RFQ, please provide the following information and data in order for us to send you competitive pricing based on your requirements.a) 2D part drawings in PDF or JPG format & 3D part drawings in UG, PRO/E, SOLIDWORKS, CATIA, CAD, STP, X_T, IGS, PRT, DWG, or DXFb) Resin information (Datasheet)c) Annual quantity requirement for parts

Q: What shall we do if we don't have part drawings?

A: You can send us your plastic part samples or photos with dimensions and we could provide you our technical solutions. We will create .

Q: Can we get some samples before mass production?

A: Yes, we will send you samples for confirmation before start of mass production.

Q: Due to time difference with China and overseas, how can I get information about my order progress?

A: Every week we send weekly production progress report with digital pictures and videos that shows the production progress.

Q: What is your leadtime?

A: Our standard leadtime for mold production is 5 weeks.For plastic parts is 20-25 days depending on the quantity.

Q: What is your payment term?

A: 50% as payment deposit, 50% balance will be paid before shipping. T/T is preferred, we can also discuss about it when we cooperate.

Q: How do you deliver the goods?

A: We have our own logistics department that could provide shipping costs via Sea or Air freight, Incoterms EXW, FOB, DDP, DDU etc. Or we can work with your appointed shipping forwarder.

Q: How can I guarantee our quality?

A: During mold making, we do material and part inspection. During part production, we do 100% full quality inspection before packaging and reject every parts that is not according to our quality standard or the quality approved by our client.

>> High Purity and Save Energy and Long Working Life Nitrogen Generator for Laser Cutting or Food Keep Fresh

>> SUNLINE FC SNIPER 150m lure fluorocarbon 100% clear fluorocarbon coating fishing line

>> Highly Effective 200W Pulse Laser Cleaning Machine Rust Spots&Paint Removal

>> Automated Multifunctional Chemical Raw Material Reactor

>> Xiaomi children's smart electric racing car 1:16 remote control car moulded toy boy gift

>> Car Accessories Anti-pinch Electric Suction Doors For BMW 5 Series F10 G30 G31 F90 Door Lock Soft Close Super Silence

>> Japanese Tsukemono Pickled Cucumber Akakappa 1.5kg

>> Bulbs Plastic Holder Making Machinery Plastic-Machinery Plastic Injection Moulding Machine

>> Various Models of Animal Feed Pellet Making Machine

>> Wholesale Factory OEM Quick Install Adjustable Height Black Sit Stand up Economy Electric Gaming Single Motor Standing Office Computer Desk

>> Floor Surface Protection Non Woven Fabric

>> 2 Aerators Brass 3 Ways Filter Water Pure Drinking Water Faucets

>> Large Event Tents Hot Sale China Auto Large Marquee Trade Show Outdoor Car Garage Tent for Event

>> Chinese Cheapest 26 Inch 36V 350W with Battery 12ah Electric Mountain Bike

>> High-Performance SS304 Decanter Centrifuge for Effective Filtration Solutions

>> Clear Thumbprint Razor / Singel Blade Max Security Shave Razor /Jail Prison Orange Clear Razor

>> Customized Waste Plastic Double Shaft Shredder/Shredding Machine Blade

>> 1540 12kw CNC Open Type Laser Stainless Steel Fiber Laser Cutting Machine for Plate

>> CE Standard Universal Milling Machine XL6236

>> Little Bee Cat Electric Toy Intelligent Tease Cat Stick Interactive Hi Pet Cat Toy Car

>> Plastic Film Bottles Recycling Machine Shredder Granulator

>> New Hot Customized High CRI 80 90 95 Anti-Glare Square or Round 5W-40W Ambient Spot Lighting

>> Paste Heating Melt Constant Temperature Mixing Mixing Barrel Mixer

>> Pure Aluminum Ingot Continue Casting Machine

>> Whitening OEM Coffee Body Scrub Private Label for Reduce Stretch Marks

>> CQ6133 38mm Bore Metal Lathe Machine with CE standard

>> UV CO2 Fiber Flying/Fly Laser Marking / Printing/Engraving/Engraver/Marker/Printer Machine for /Plastic/Copper/Stainless Steel/Aluminum /Leather/Pipe /Tube

>> Fully Automatic Polyethylene Bonding Pearl Cotton Sheet Hot Plate Lamination EPE Foam Hot Air Laminating Machine

>> Suji Vmc Heavy-Duty CNC Lathe Milling Machine Center Metal Lathe Tools

>> Gym Equipment Gym Fitness Pedals Air Bicycles Exercise Spinning Air Bike Fun Bike