Wood Carving Cutting CNC Router 5 Axis with Auto Tool Change

Basic Info.

Model NO.

RB-F5-1930-Z08

Application

Wood

Process Usage

CNC Non-Conventional Machine Tools

Movement Method

Contour Control

Control Method

Semi-Closed Loop Control

Numerical Control

CNC/MNC

Processing Precision

0.01~0.02(mm)

Performance Classification

High-End CNC Machine Tools

Certification

GS, CE, RoHS, ISO 9001

Condition

New

X Axis Effective Stroke

1900mm

Y Axis Effective Stroke

3000mm

Z Axis Effective Stroke

800mm

B-Axis Rotation Angle

+/- 130 Degree

C-Axis Rotation Angle

+/- 540 Degree

X/Y Axis Maximum Speed

35m/Min

Z Axis Maximum Speed

20m/Min

Repeat Accuracy

+/-0.05mm

Voltage

380V

Total Power

9.9-29.1kw

Spindle Power

3-20kw (Customizable)

Frequency

50Hz

Controller

Taiwan Syntec

Spindle

Hiteco

Transport Package

Export Safety Packing (Customized Packing)

Specification

L5100*W2610*H3982mm

Trademark

RBT

Origin

Quanzhou, China

HS Code

84659990

Production Capacity

200set/Month

Packaging & Delivery

Package Size

440.00cm * 260.00cm * 440.00cm

Package Gross Weight

3500.000kg

Product Description

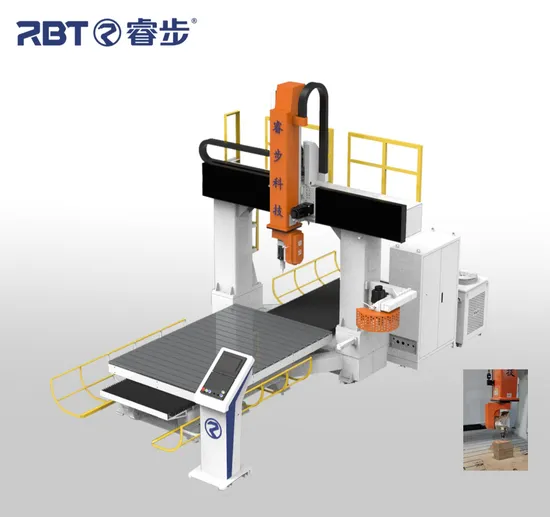

Product DescriptionWood Carving Cutting CNC Router 5 axis with Auto Tool Change

Introducing our Wood Carving Cutting CNC Router 5 axis with Auto Tool Change, the ultimate solution for precision machining. This 5 axis CNC machine offers unparalleled accuracy and efficiency, making it ideal for a wide range of applications. With automatic tool changing capabilities, you can streamline your workflow and increase productivity. Experience the power of our 5 axis CNC router and take your machining to the next level

Product Parameters

Specifications:

| Machine speed | Fast movement speed /G00 | X | 35m/min |

| Y | 35m/min | ||

| Z | 20m/min | ||

| Processing speed/G01 | 0~10m/min | ||

Spindle | Power | 5.5KW | |

| Cooling | water cooling | ||

| RPM | 24000RPM | ||

| Working travel | X axis | 1900mm | |

| Y axis | 3000mm | ||

| Z axis | 800mm | ||

| C axis | ±540° | ||

| B axis | ±130° | ||

| Max workpiece | X axis | 1400mm | |

| Y axis | 2500mm | ||

| Z axis | 550mm | ||

| Repeated Positioning Accuracy (within 300mm) | X,Y axis | ±0.05mm | |

| Z axis | ±0.05mm | ||

| B,C axis | 15 arc seconds | ||

| Total power | ≈14.5KW | ||

| Input voltage | 3-380V | ||

| Tool holder specification | ER32 | ||

| Control system | Syntec | ||

| Working table | 1500*2280mm | ||

| Dimension | 5100*2610*3982mm | ||

| Weight | ≈2900kg | ||

Machine details with photos

The advantage of five-axis machining center in wood mold processing are reflected in the following aspects:

1. Advanced Wood Carving Cutting CNC Router with 5 axis capability and Auto Tool Change feature.

2. Ideal for complex 3D designs, ensuring precise and smooth finishing in a single operation.

3. Five-axis linkage technology reduces processing time and increases production efficiency.

4. High precision machining for dimensional accuracy and surface smoothness, meeting quality standards for high-end markets.

5. Automatic tool change system reduces downtime and enhances processing continuity for versatile wood product manufacturing.

6. Optimized processing paths minimize material wastage, lowering production costs.

7. Suitable for a variety of materials including hardwood, softwood, and composite materials.

8. Customizable production for small batches and personalized market demands.

9. Integrated CAD/CAM software streamlines the design-to-production process seamlessly.

10. High automation reduces manual labor requirements, improving operational efficiency.

Machine Application

Some specific application cases of five-axis machining centers in wood mold processing include:

Complex furniture parts, wooden artwork carving, wooden musical instrument parts, wooden toy processing, wooden decoration manufacturing, wooden model making, wooden packaging box processing, wooden display stand manufacturing, making wooden mechanical parts, molds and other wooden components for industrial purposes, wooden decoration carving, and wooden mold processing.

Certifications

CE Certificate:

Company Profile

Packaging & Shipping

1.Plastic film packaging and put in plywood wooden cases or according to customer's requirements.

2.Shipping : Container transport.

>> Shuttle Holder for 7#10# Multi-Needle for Computerized High Speed Multi-Needle Machine

>> Concrete Mix Air Entrainment Meter with Pressure Chamber price

>> OEM Custom Stainless Steel Hardware Fastener Non-Standard Fasteners

>> New products sale pistachios for sale bulk pistachio nuts+high quality organic nuts pistachio at good price

>> Thickened Warm Flannel Winter Quilt Home Student Dormitory Queen Full Size Comforter Core

>> Real Factory Ceiling T Bar Machinery and Cross Tee T Grid Roll Forming Machine

>> Non Woven Surgical Disposable Shoe Cover Making Machine Made in China

>> High Quality Mediun Excavator PC240 25ton Digger for Sale

>> Light Duty Rotary Tiller Cultivator Chain Driven

>> OPC Drum Large Capacity Prospect Neutral Boxes, Branded Boxes and Custom Ricoh HP Toner Cartridge

>> 12-48V Aluminum LED Strobe Rotate Emergency Safety Warning Beacon Flashing Light

>> Plastic Litchi Bottle Production on Extrusion Blow Molding Machine

>> Good Price Stainless Steel Frameless Glass Door Lock

>> Yonghong Construction Decoration High Quality Waterproof Interior WPC Material Fluted Wall Panel

>> Adjustable Height Orchard Fruit Collection Machine Multi-Function Orchard Fruit Harvester

>> Cheap Price Hot Seller 8L 10L 30L 40L 47L Gas Cylinder Oxygen Filling Cylinder for Hospital Use

>> Fiberglass Non-Slip Tray Plastic Rectangle Fast Food Serving Tray for Restaurant

>> 19-Inch LCD Advertising Media Player Video Player TFT Elevator Screen WiFi Network HD Full Color LED Digital Signage

>> Aerated Block Hollow Brick Limestone Granite Cutter Vertical Saw Blade Brick Cutter 35 Type (Vacuuming Type) Marble Firebrick Cut

>> Stylish Vegan Leather Shoulder Bag for Women with Heart Design Satchel

>> Factory Price Full Automatic High Productivity Computerized Embroidery Quilting Machine

>> Highly Durable Stainless Steel Fiber Sintered Felt Filter Disc Made of Stainless Steel Material

>> Jinghua Best Quality End Clear 190X190X80mm Glass Block/Brick

>> FGB High Quality Spherical Plain Bearings GE35ES GE35ES-2RS GE35DO-2RS bearing made in China

>> Hot Sale Traditional Chinese 52cm Male Acupuncture Model

>> Log Saw Tissue Cutting Machine Price for Facial Tissue Paper

>> Square Natural Stone Marble Mosaic for Backsplash Wall Tile

>> High Performance Industrial Spray Booth with Integrated Heating Recycling System

>> HVAC Duct Manufacturing Tdf Flange Roll Forming Machine

>> Amazon Explosion Cotton Linen Soap Bag Natural Plant Fiber Soap Foaming Bag Sisal Ramie Soap Storage Bag