Customized 9-32mm High-End Pet Plastic Steel Belt Equipment for 100cc Metering Pump

| US$105,000.00-135,800.00 | 1 Set (MOQ) |

Basic Info.

Model NO.

HL-PET

Type

Sheet Extruder

Plastic Processed

Pet

Product Type

Extrusion Molding Machine

Feeding Mode

One Feed

Assembly Structure

Separate Type Extruder

Screw

Twin-Screw

Engagement System

Full Intermeshing

Screw Channel Structure

Deep Screw

Exhaust

Don′t Exhaust

Automation

Automatic

Computerized

Computerized

Width

9-32mm

Thickness

0.4-1.2mm

Pull

200-1500kg

Paper Core Diamete

406*150mm

G.W

20kg/Roll

Screw Diameter (mm)

110

Capacity /24h

300-330kg

Transport Package

PE Film

Specification

9-32mm

Trademark

HL

Origin

Shenzhen

HS Code

3923900000

Production Capacity

100stes/Year

Product Description

https://membercenter.made-in-china.com/productmanage.do?xcase=view&prodId=ltIRFEhZLCVy&queryGroupId=&queryCatCode=&pageSize=30&queryState=-1&prodUpgradeActivity= Product DescriptionPET plastic steel belt, also known as PET polyester belt, is a type of conveyor belt made from a combination of polyethylene terephthalate (PET) and steel cords. This unique combination of materials provides the belt with exceptional strength, durability, and flexibility, making it suitable for a wide range of industrial applications.

Features: 1.High Tensile Strength: The steel cord reinforcement provides exceptional tensile strength, making it suitable for heavy-duty applications.

2.Durability: PET material combined with steel cords ensures long-lasting performance, even in harsh environments.

3.Flexibility: Despite its strength, the belt remains flexible, allowing it to conform to the contours of conveyor systems.

4.Resistance to Wear and Tear: The belt is highly resistant to abrasion, making it ideal for transporting abrasive materials.

5.Temperature Resistance: It can withstand a wide range of temperatures, making it suitable for both high-temperature and low-temperature applications.

6.Chemical Resistance: PET plastic steel belts are resistant to many chemicals, enhancing their suitability for various industrial environments.

7.Low Maintenance: The durability and resistance properties reduce the need for frequent maintenance, lowering operational costs.

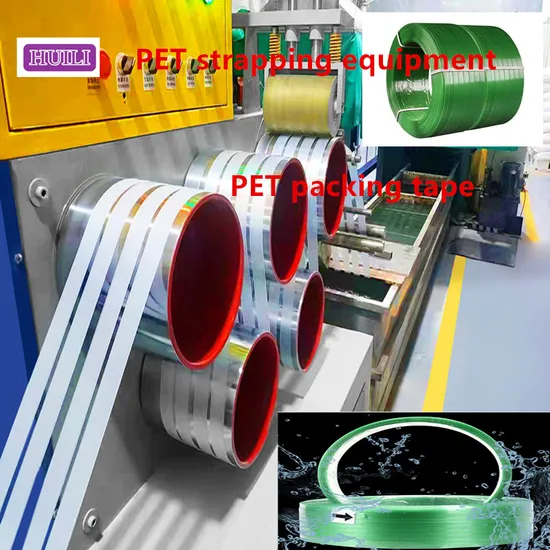

PET packaging belt production line process flow

Loading →Mixing raw materials → Pre-drying raw materials → Vacuum dehumidification of raw materials →Melting and metering extrusion of raw materials →Cooling and forming of raw materials (with raw materials) →Preheating the oven → Primary stretching →Secondary stretching → Embossing → Oven tempering and shaping →Cooling →Finished product winding

| Model | PET-2 | PET-3 | PET-4 | PET-6 | PET-8 |

| Raw materials | Bottle flakes/crushed materials | ||||

| Number of tapes | 2 | 3 | 4 | 6 | 8 |

| Width (mm) | 9-32 | ||||

| Width (mm) | 0.4-1.2 | ||||

| Maximum line speed(m/min) | >=150 | >=150 | >=150 | >=150 | >=150 |

| PLC control system | PLC | PLC | PLC | PLC | PLC |

| Screw Model | 90 | 100 | 125 | 150 | 180 |

| Reducer model | 200 | 250 | 280 | 315 | 350 |

| Dryer tank | 3000L | 4000L | 5000L | 6000L | 6000L |

| Dehumidifier | 1000 | 1000 | 2000 | 3000 | 3500 |

| Metering Pumps | 100CC | 100CC | 100CC | 100CC | 100CC |

| Screen Changer | Single cylinder | ||||

| Production capacity /24 H | 5-6T | 7-8T | 10-12T | 12-15T | 18-20T |

Detailed Photos

Advantages of PET plastic steel belt equipment:

Economical and efficient: long service life, low maintenance requirements, high degree of automation, it is an economical and efficient equipment for packaging materials.

Efficient: high strength and durability ensure efficient material handling, sustainable production, and reduced downtime.

Safety: The sturdy structure ensures safe and reliable operation and minimizes the risk of belt failure.

Energy saving: energy saving and environmental protection, high output and low power consumption.

FAQ

Q: What is the voltage of the PET plastic steel belt equipment?

A: 380V/50HZ, three-phase (customization supported)

Q: What is the extrusion capacity of the PET plastic steel belt equipment?

A: Different models have different extrusion capacities, ranging from 150-600KG/H

Q: Where does the PET plastic steel belt equipment come from?

A: China.

Q: What are the certifications for PET plastic steel belt equipment?

A: ISO CEO certification.

Q: What is the minimum order quantity for PET plastic steel belt equipment?

A: 1 set

Q: What is the weight of the PET plastic steel belt equipment?

20T, 40GP container * 3PCS

>> Weldon custom powder coating ip65 PS rittal electrical box enclosure

>> Fitness Equipment Low Price Multifunction Air Walker Exercise Machine

>> Sunpring Machime Making Tilapia Fish Feed + Floating Fish Feed Pellet Mill Making Machine + Fish Feed Pellet Making Machine

>> Motorcycle Spare Part Fuel Injector for Super Cub / Wave125-I (2018)

>> Inflatable PVC Double Water Sildes with Ball Pool for Children Jungle Gym Inflatable Water Play Equipment Slide with Air Blower

>> Ergonomic PU Home Office Adjustable Swivel Leather Executive Conference Chair with Armrests

>> China Manufacture Price Groove Machine Cardboard V Grooving Machine

>> Double Disc Refiner Continuous Beating of Pulp Based on Waste Paper for Paper Pulp Making Machinery

>> Growatt Inverter on Grid Mod 10000tl3-X with There Phase

>> 3MP 16mm 2/3" Mv-Ld-16-3m-a C-Mount Lens Industrial Machine Vision Lens for Vision Inspection

>> Frozen Oyster Mushroom Export

>> 300L Solar Water Heater for Home Use with Best Price

>> Bicycle Motorcycle Truck /Car ATV Radial Tyre/Tire Agriculture Mould

>> Arrow Dripper and Accessory Watering Tree Drip Irrigation

>> 100 Disposable Chopsticks Paper Sleeve Bamboo Wooden Bulk Disposable Utensils

>> Premium Spoon and Chopsticks Production Line for Businesses

>> High Quality Double Layers Twisted Loop Cleaning Details Car Washing Towel

>> All Kind of Tools in China

>> Simplicity Airbag Touch Screen Diving Water Splashing Transparent PVC Waterproof Phone Case

>> 5G 8.5G 13G 17.5G High Carbon Steel Hooks Snakeheaded Fish Soft Frog Lure Fishing Frog Bait

>> Wholesale 10W 2A USB Adapter Dual 2 Port Universal Mobile Phone USB Qc3.0 Car Charger for iPhone

>> Yuntai Factory Good Quality Arena Plough

>> Stainless Steel 304 316 Small Trim Head Torx Decking Wood Screw with Serration, Type 17 Point Knurl Thread Timber Decking Screw

>> 1/4′′ PU220-02 2/2 Way Brass Water Valvula Solenoide Direct Acting Solenoid Valve 110VAC 220VAC 24VDC

>> Mono Aluminum Phosphate Powder Refractory Castable, Ramming Material Binder

>> High Quality Turntable Packing Machine Line Candy Wrapping Machine pita bread packing machine

>> Outdoor Street PVC Vinyl Banner Advertising Custom Design Digital Printing Outdoor Advertising PVC Flex Banner Printing

>> Large Crawler Excavator Sy980h Sy980h-S Bucket 5.5-8m³ 478 or 574kw Low Fuel Consumption Automatic Acceleration Deceleration Function Reduces Engine Speed

>> NEMA Tefc Single-Phase Brake Motor with UL and CSA

>> Laptop 9I I7-1355u 16g/1t 13.3inch Dual Touch Screen Office Notebook