High Quality Rubber Mixing Mill Machine

| Negotiable | 1 Set (MOQ) |

Basic Info.

Model NO.

X(S)K - series

Automatic Grade

Semi-Automatic

Power Source

Electric

Type

Open Mixing Mill

Transport Package

Wooden Case

Specification

XK-150, 360, 400, 456, 560

Trademark

BIZ

Origin

China

Production Capacity

20 Per Year

Product Description

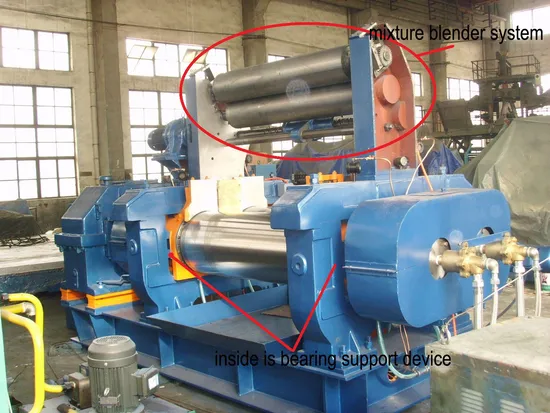

High Quality Mixing Mill Rubber MachineApplications:

The machine is used for plasticizing ,mixing and sheeting of plastics and rubbers

Features:

1 The rollers are made of chilled alloy cast iron with wear-resistant hard surface. The cavities of rolls are machined.

2 Overload protection devices are provided to protect the main parts from damage due to overload.

3 The reverse current plugging system is provided above the rolls. In case of emergency. The safety rod is pulled down and the rolls will be stopped immediately.

4 The roll gap can be easily adjusted by hand wheel.

5 The bed-plate of the machine is integral. The installation of the machine is simple

FEATURES

H TYPE Series of Heavy-Duty Mixing mill, Warm-up Mill and Feeding Mill are used for auxiliary machine under internal Mixer which is developed by our corporation with high starting point and level. They have now arrived advanced international standards.

The series have two forms on structure. The first structure: front and rear rolls are cast steel rolls with alloy, roll surfaces are treated by hard facing to make them bigger strength, higher hardness, better bending resistance and resistance to torsion as well as to be of wear-resisting and corrosion resisting surfaces; the driving system has been adopted 4-stage cylinclrical gearbox with two output shafts and full hard teeth surface, and front and rear rolls are connected through a pair of cross universal-joint coupling. The driving type is adopted a enclosed drive to make it bigger driving power and higher driving efficient; the control system can be operated through site-control and combined it with telecontrol. The second form: the front and rear rolls are rolls for chilled cast iron with alloy; driving system is 3 stages cylindrical gearbox with full hard teeth surface which brings velocity ratio gears driving. The bearing of these two forms are all used with double row contact rolling bearing, It has these characteristics: well-cooling, smoothly-drive, low-noise and high-effectiveness.

The machine is separately suitable for rubber sheeting of the auxiliary machine of mixer as well as warming, refining of compounds which are needed by 3 rolls/4 rolls calendars and supply compounds for them.

TECHNICAL SPECIFICATIONS

| Type | XK-150 | XK-250 | XK-300 | XK-360 | X(S)K-400 | X(S)K-450 | X(S)K-560 | |

| Working diameter of rolls (mm) | Ø150 | Ø250 | Ø300 | Ø360 | Ø400 | Ø450 | Ø560/510 | |

| Working length of rolls (mm) | 320 | 620 | 750 | 900 | 1000 | 1200 | 1530 | |

| Working linear speed of front roll(m/min) | 8 | 15.1 | 15.1 | 16.25 | 18.65 | 24.5 | 27.7 | |

| Max gap (mm) | 10 | 10 | 10 | 10 | 15 | 15 | 15 | |

| Capacity per. batch(kg) | 1-2 | 10-15 | 15-20 | 20-25 | 18-35 | 25-50 | 50-65 | |

| Driving motor power(kw) | 7.5 | 18.5 | 22 | 30 | 37 | 55 | 95 | |

| Overall dimension (mm) | L | 1080 | 3400 | 3580 | 3940 | 4250 | 5200 | 6120 |

| W | 796 | 1350 | 1550 | 1780 | 1850 | 2380 | 2280 | |

| H | 1415 | 1500 | 1695 | 1740 | 1870 | 1770 | 2000 | |

| Weight (kg) | 1100 | 3500 | 5205 | 5670 | 7600 | 13000 | 22000 | |

| Notes | Bearing | Nylon bush grease LUB Copper sleeve oil LUB | ||||||

| MODEL | Dia of roll | Working length of rolls(mm) | Max gap(mm) | Roll speed ratio | Working linear speed of front roll(m/min) | Capacity per. batch (kg) | Motor power (kw) | Overall dimension(mm) | Weigh(kg) |

| X(S)K-360B | Ø360mm | 900mm | 10mm | 1:1.25 | 16.25 | 20-25 | 30 | 2800×1850×1750 | 6000 |

| X(S)K-400B | Ø400mm | 1000mm | 10mm | 1:1.27 | 20 | 20-35 | 45 | 2900×1900×2070 | 7500 |

| X(S)K-450B | Ø450mm | 1200mm | 15mm | 1:1.27 | 23.2 | 25-50 | 55 | 3300×1700×2000 | 10500 |

| MODEL | DIA OF ROLLER | Working length of rolls(mm) | Max gap(mm) | Roll speed ratio | Working linear speed of front roll(m/min) | Capacity per. batch (kg) | Motor power (kw) | Overall dimension(mm) | Weigh(kg) | ||||

| X(S)K-460H | Ø460mm | 1220mm | 15mm | 1:1.22 | 14.54 | 25-50 | 75 | 5200×2400×2590 | 14700 | ||||

| X(S)K-560H | Ø560mm | 1524mm | 15mm | 1:1.12 | 27.7 | 75-100 | 110 | 5970×2200×1600 | 22000 | ||||

| X(S)K-550B | Ø550mm | 1500mm | 15mm | 1:1.22 | 27.94 | 50-65 | 110 | 5870x2475x2645 | 28000 | ||||

>> Multifunction Magic Two Double Side Longe Handle Dish House Keeping PP Brush

>> Fp10000W Amplifier Professional Speaker PRO Audio System Line Array Speaker Power Amplifier

>> Regular Fit Hoodie Heavyweight Cotton Summer Pullover Men Hoodie 2021 New Design Winter Hats Breathable Camouflage Custom

>> Multi-Specification Sweat Room Sauna Room Wall Salt Board Salt Brick

>> Furniture Component Bar Stool Chair Garden Set Furniture Set Rattan Set

>> Agricultural Disc Ridger with Tractor Mounted High Quality

>> High Visibility Innovative Outdoor LED Display Module Outdoor Display Screnn Video Wall

>> Dental Lab Surgical Microscope with Camera HD Synchronization of Various Display

>> Furniture Grade Finger Joint Core Cheap Price Melamine Board Melamine Faced Plywood

>> Women Sexy Body Bodysuit Slimming Waist Trainer Shapewear

>> E1 Type Spherical Roller Bearing, Super Load-Bearing, Stable and Durable, Improve Equipment Performance "German Technology Ee126096D/126150

>> Diammonium Phosphate DAP 21-53-0, DAP Fertilizer

>> Injection Molding Machines Haichen Hck 1500 Ton Injection Molding Machine

>> Waterproof Winter Snow Boots for Kids with Fur Lining

>> Improved Super Arch Fender (TD-BPE) /Marine Fender//V Fender

>> Chef Knife Bag with Zipper Backpack for Knives and Chef Tools

>> GF125 Tubular Milk Cream Centrifuge Separator Machine with Different Specifications and Large Capacity

>> Almond Machine Industrial Food Packaging Wood Spoon for Powder Drip Coffee Pet Jelly Stick Pouch Packing Machines Multihead

>> Single Paper Bowl Forming Machine/Plate Bowl Machine/High Quality Paper Plate Machine

>> Body Disease Screening Device Hospital Diagnosis Equipment Machine Disease Detective Machines

>> Factory Price Cardboard Making Pad Expanding Cushion Cutting Paper Shredder Machine

>> Like Cheto High Stability Low Cost Horizontal CNC Deep Hole Drilling Machine

>> Kids Backpack Plastic Doll School Bag Cute Cartoon Travel Rucksack Children′s Toys

>> 9817604780 Car intake grille Auto parts grille for peugeot 301 (M33R) 2017

>> GAPV hot sale good price plating tail cover back truck usa version 2010 years 76801-02700

>> Customized Carbon Steel Water Pressure Tanks Rubber Bladder Vessel

>> Professional Insurance Shipping Agent DDP International Air Freight Rates to Russia Kazakhstan Belarus Georgia Latvia Estonia

>> Semi-Automatic China Bottle Blowing Machine

>> CNC Steel Plate Punching Drilling Marking Machine FINCM CNC Hydraulic 1200KN Punching Hydraulic Hole Punching Machine

>> Diamond Wire Saw for Quarry