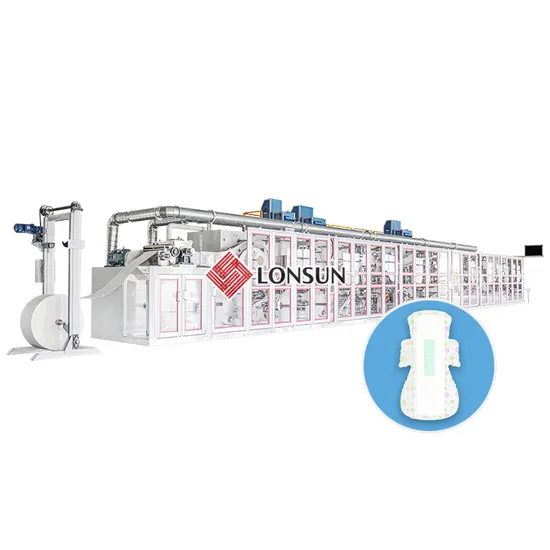

Full Automatic High Speed Servo Control Women Maxi Sanitary Napkin Pads with Wings Making Machine

| US$190,000.00-420,000.00 | 1 Set (MOQ) |

Basic Info.

Model NO.

SR-HY800

Real Running speed

>800PCS/min

Automatic Grade

Automatic

Certification

CE, ISO, CCC

Condition

New

After-sales Service

Life-Long

Voltage

360V, 50Hz

Power

320kw

Speed

800ppm

Driving

Servo Motors

Transport Package

Wooden Crates

Specification

28*6*4 (L*W*H)m (for reference)

Trademark

LONSUN

Origin

Fujian, China

HS Code

84418090

Production Capacity

40sets/Year

Packaging & Delivery

Package Size

2800.00cm * 600.00cm * 400.00cm

Package Gross Weight

33000.000kg

Product Description

| Machine Description | ||

| Machine Type | High Speed Full Automatic Sanitary Pads Production Line | |

| Finished Product | Maxi Pads with Wings (180-420mm) | |

| Machine Driving | frequency control/semi-servo control/full-servo control | |

| Main Parameters | ||

| Production speed | 600/800/1000 pcs/min. | |

| Power supply | 3 phase, 380V, 50Hz. | |

| Total power | 180-320KW (hot melt applicator and air compressor excluded) | |

| Overall size | 28×6×4 (L×W×H)m (for reference) | |

| Main Configurations | ||

| 1. | Frequecy motor/servo motor driving controlled by PLC with touch screen; | |

| 2. | Raw materials automatic unwinding with tension control and auto spliciing units; | |

| 3. | Raw Materials web guiding units; | |

| 4. | Single high speed cell mill; | |

| 5. | Single drum former for continuous fluff core formation; | |

| 6. | Single SAP applicator; | |

| 7. | Fluff core embossing and cutting units; | |

| 8. | SAP paper feeding & cutting units; | |

| 9. | Air-laid paper feeding & cutting units; | |

| 10. | Topsheet unwinding and cutting unit; | |

| 11. | Side-gather non-woven fabric unwinding and slitting unit (option); | |

| 12. | Side-gather (3pcs topsheet type) embossing unit (option); | |

| 13. | ADL/anion chip unwinding and cutting unit; | |

| 14. | Channel embossing unit; | |

| 15. | PE film unwinding and cutting unit; | |

| 16. | Release paper applicating unit; | |

| 17. | Contour sealing unit; | |

| 18. | Shape cutting unit; | |

| 19. | 90 degree rotating unit; | |

| 20. | Folding and wrapping unit (fast-easy package or straight package without folding); | |

| 21. | Count and outputting unit; | |

| 22. | Stacker (option); | |

| 23. | Packing machine (option); | |

| 24. | Dust collection filter system (option). | |

>> Oval Bread Proofing Basket Linen Liner Cloth Sourdough Rising Basket Baking Gifts for Bakers

>> Large Suction Hose Small Household Grain Pumping Corn Conveying Machine

>> Hy Linear Driver LED GU10 Light for Bedroom

>> Automatic Face Mask Pillow Type Bag Sealing Packing Machine High Speed Wet Tissue Hand Towel Packaging Machines

>> Rotary drum washer minerals sand iron ore washing machine

>> Wholesale Anti Mosquito Retractable Screen Roll Up Metal Window Coverings

>> 1~10 Ton 5m 10m 15m CD MD Type Electric Wire Rope Hoist

>> Warm Knitted Fashion Scarf High Quality Feel Pashmina Scarf

>> High Cost Performance Good Condition Used Plastic Injection Turnover Chair

>> FT8210H Magnetic Flow Meter Sensor Indicator

>> Cotton White Hotel Hand Terry Face Hotel Bath Towel 100% Cotton for Hotel Top Cotton Hotel Bath Towel Set Shower Towel Set

>> Metal Working Tools 3015 1000W 1500W Laser CNC Plasma Cutting Machine

>> High Performance Genuine Body System Parts Light Lamp Assy 921024L500 92102 4L500 92102-4L500 Fit For Hyundai Korean Car

>> Latex Pillow / Natural Soft Contour Massage Pillow for Home and Hotel

>> Fat Removal 980nm 1470nm Diode Laser Lipolisis Vaser Liposuction Endolaser Lift Machine

>> Integrated Solar Mobile Traffic Light Motor Vehicle Pedestrian Light

>> Servo Control High Speed Automatic Small Soft / Hard Candy Packing Machine

>> Stainless Steel Blades Fiber Optic Anesthesia Laryngoscope Set

>> LED 110V 220V 12W 24W Water Treatment Germicidal Tube Sterilizing Ultraviolet UV Lamp 240nm 250nm 254nm 265nm 275nm UVC Light for Air Sterilization

>> Industrial Electrostatic Powder Supply Center

>> 6 Inch IPS Touch Screen IP67 Waterproof Industrial Handheld Android PDA 4G LTE

>> Direct factory sale nordic study table children tables kids' tables computer desk

>> 15kg side gusset PP woven BOPP Horse Pet Feed Bag with Matt Lamination

>> medical face mask- Manufacturer of disposable medical mask of HAIDIKE from china

>> Computer Controlled Torque Rheometer for Extruder Mixing Unit Applications

>> Clear Self Adhesive Holographic Overlay for ID Card, Easy to Apply and Strong Hold

>> Garment Accessories Crocodile Embroidery Patch and Logo

>> CE Ex1800K Mini Excavator Backhoe Loader Slippage Mini Small Hydraulic Crawler Deisel Excavator for Construction

>> Plastic Milk Shell for Cow Milking

>> China Suzhou Zhangjiagang Plastic Screws Recycling Machine