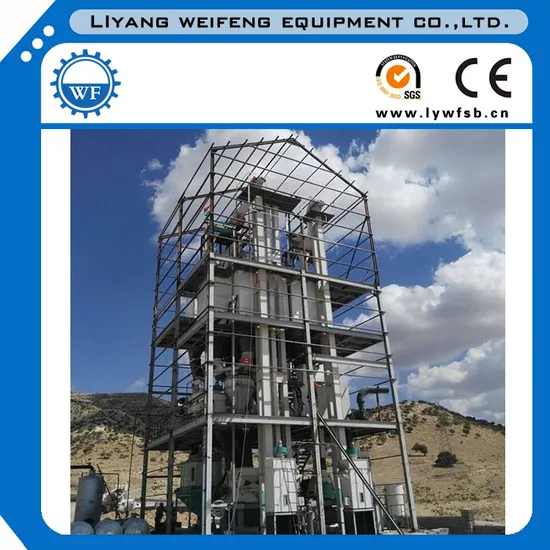

1-10t/H Premix Feed Production Line

| US$3,800.00-24,000.00 | 1 Piece (MOQ) |

Basic Info.

Model NO.

Szlh250,Szlh320,Szlh350,Szlh400,Szlh420,Szlh508

Processing Object

Animal-Derived Feed

Processing Technics

Crushing-before-Mixing

Screen Mesh

With Screen Mesh

Grinding Equipment Type

Feed Hammer Mill

Pellet Mill Type

Ring Die Pelleter

Bulking Machine Type

No

Expanding Method

No

Condition

New

Applicable Materials Shape

Feed/ Granular

Warranty

1-3years

Certification

CE, ISO, SGS

Delivery Time

20-60days

Transport Package

Pallet or Nude Packing

Trademark

LYWF

Origin

China

HS Code

8436100000

Production Capacity

20 Sets/ Month

Product Description

Company ProfileAbout our factory

Our factory Liyang Weifeng Equipment Co., Ltd. is a professional manufacturer specialized in designing, making high quality feed pellet mill and building turn key feed pellet production line,premix feed production line, concentrate feed production line . With 20 years' experience, professional technical R&D team.

We had built 1-30t/h feed pellet production lines(chicken feed pellet lines, cattle feed pellet lines, fish feed pellet lines and so on) in: Russia, Romania, Thailand, Malaysia, Ukraine, Iraq, Algeria and so on.

Process

Total process for premix feed production line

Raw material receiving →Grinding →Mixing →Packing

Detailed processes of feed pellet mill line, poultry feed production line

1. Raw materials receiving Process:

Raw materials can be corn, rice bran, soybean, grain, wheat, soybean meal / cake and etc. Precleaner can remove the impurities in raw materials.

2. Grinding Process:

The feed grinder can grind the raw material ingredients to the required size. There are various hammer mills which can satisfy different requirements.

3. Mixing Process:

Mixing is considered to be one of the essential operations in feed pellet processing. Lack of proper mixing may lead to reduced diet uniformity, affecting the feed pellet quality.

4. Packing Process

The premix feedshould be packed for transporting, storing or selling.

8. Automatic PLC Control System(Customized):

With the automatic PLC control system, the production line is with high efficiency and convenient operation

Main technical parameters

1. Grinding process----Hammer mill SFSP

| Item | 66*40 | 66*60 | 66*80 | 66*100 | 66*120 | |||||||

| Rotor diameter (mm) | 660 | 660 | 660 | 660 | 660 | |||||||

| Spindle rotate speed (rpm) | 2960 | 2970 | 2970 | 2980 | 2980 | |||||||

| Hammer line speed (m/s) | 102 | 102 | 102 | 102 | 102 | |||||||

| Grinding room width (mm) | 400 | 600 | 800 | 1000 | 1200 | |||||||

| Hammerquantity(fine grinding) | 40 | 56 | 84/116 | 120 | 136 | |||||||

| Power( kw) | 37 | 45 | 75 | 90 | 110 | 132 | 160 | 200 | 220 | |||

| Capacity(t/h) | 1-3 | 2-5 | 5-7 | 6-8 | 8-10 | 10-12 | 12-15 | 15-20 | 20-25 | |||

| Normal air volume ( m3/min) | Fine grinding | 55 | 60 | 78 | 95 | 102 | 145 | 155 | 190 | 205 | ||

2. Mixing process----Mixer SSHJ

| Item | Effective Capacity(M3) | Mixing amount(KG) | Mixing time(S) | Mixing | Power(KW) |

| homogeneity(CV%≤) | |||||

| SSHJ0.1 | 0.1 | 50 | 30~120 | 5 | 2.2(3) |

| SSHJ0.2 | 0.2 | 100 | 30~120 | 5 | 3(4) |

| SSHJ0.5 | 0.5 | 250 | 30~120 | 5 | 5.5(7.5) |

| SSHJ1 | 1 | 500 | 30~120 | 5 | 11(15) |

| SSHJ2 | 2 | 1000 | 30~120 | 5 | 15(18.5) |

| SSHJ3 | 3 | 1500 | 30~120 | 5 | 22 |

| SSHJ4(s) | 4 | 2000 | 30~120 | 5 | 22(30) |

| SSHJ6(s) | 6 | 3000 | 30~120 | 5 | 37(45) |

| SSHJ8(s) | 8 | 4000 | 30~120 | 5 | 45(55) |

Our services

(1) Warranty time: 1-3 years, from the date which the product is qualified commissioning. Any damage except the wrong operation during warranty period is repaired freely. But the travel and hotel expenses should be count on buyer.

(2) Commissioning services: the product's installation and commissioning at the demand side, our engineers will not leave there until get your agreement.

(3) Training services: our engineers will train your staff to operate it during the period of installation and commissioning, and they will not leave there until your staff can operate it properly and normally.

(4) Maintenance services: any malfunction happened, once you enquiry us, we will reply you within 48 hours except the special reasons.

(5) Lifelong services: we provide lifelong services for all the products we sold out, and supply the spare parts with discount price.

Contact us

Welcome to visit our feed machine factory, our factory is near Nanjing Lukou Airport and Shanghai Pudong Airport.

Best Regards.

>> China Factory Customized 24V RGBW/RGB+W LED Strip Light for Decorative Lighting

>> Pet Preform Blow Moulding Machine for 5L Edible Oil Bottles

>> Blue Yellow Gray and Red in One Brand Copy Replica Fashion Luxury Cacual Shoes

>> High-Speed Railway Toilet Parts Made of SMC Composite Material

>> China Manufacturer Portable 3ml Weight Loss Insulin Injection Pen

>> SKMEI 1538 erkek kol saati japan movt quartz watch stainless steel bezel sports watches

>> China Direct Wholesale Hydraulic Floor Jack Factory 2024 New

>> Mini Backpack Easy-Carry Portable Pulse Laser Cleaning Machine

>> Outdoor Waterproof LED Flood Light 30W-400W High-Pole Lamp LED Flood Light Lamp

>> Morden Outdoor Furniture Home Hotel Restaurant Patio Garden Sets Dining Table Set Aluminum Rattan Plastic Wood Synthetic Wood Outdoor Chair

>> High Demand Custom CNC Machining Processing Parts PTFE POM Peek PS PP Plastic Milling Turning Parts Service

>> High Capacity Pencil Case, Big Pencil Bag Pouch Box Organizer Pen Case, Portable Journaling Supplies with Easy Grip Handle & Loop, Asthetic Supply for Girls Adu

>> Eye Drops Bottles Injection Molding Machine

>> Manual Agitator Mixer Surface Drive Flow Meter Helicopter Coreless Gear Submersible Driveshaft Fan 2 Balde Outboard Propeller

>> Tycorun 48V/60V/72V LiFePO4 Li-ion Battery Pack Swap Station for E-Bike Electric Scooter Batteries

>> Factory Wholesale Price 6061 7075 Aluminium Alloy Rod Aluminium Round Bar Metal Rod

>> Portable Ultrasonic Spot Welding Machine 500w Plastic Welder For PVC Conveyor Belt

>> Factory Supply BS1363 Electrical 4 Gang 6 Gang 16A Wall Switch for Lighting Industry

>> Double Nozzles Automatic High Accuracy Weighing Duck Down Filling Machine (RM2-4)

>> 2.5kw Potato Chips Slicing Cutter Machine Fruit Vegetable Cutting Machine

>> 3BHL000986P0006

>> Laser Beam Shaking LED Stage Lights Full Color Dyed Lamp Dance Table Lamp Disco Performance

>> Strange Design Small Dog Interactive Training Plush Stuffed Animal Pet Toy

>> Wide Operation Qjc-110 ODM OEM Custom 65mn Blade Beach Sand Cleaner

>> 2000W 3000W Laser Surface Continuous Wave Cleaning Machine for Metal Steel

>> Shr Series PVC High Speed Powder Mixer

>> Gnss Agriculture Farming Display GPS Navigation Guidance for Tractor

>> lowes exterior solid teak wood doors dutch doors

>> 720p Side View Rigid WiFi Wireless Inspection Camera Borescope for Cavity Wall Inspection for Andorid

>> Super Bright Customized Smile Cool Face Icon Neon Sign