Nonwoven Bed Sheet Folding Machine

| US$40,000.00-45,000.00 | 1 SET (MOQ) |

Basic Info.

Model NO.

ALT-ZD2000

Automatic Grade

Automatic

Certification

CE, ISO9001: 2000

Customized

Customized

Condition

New

After-sales Service

1year

Length

10m

Width

2.5m

Transport Package

Wooden Box

Trademark

ALT

Origin

China

HS Code

8451800090

Production Capacity

50m/Min

Product Description

NONWOVEN BED SHEET FOLDING MACHINEEquipment Introduction Equipment requirements: The device can process all kinds of spunlace non-woven,hot air fabric, hot-rolled fabric; acupuncture cloth, spunbond fabric, SMS, paper-plastic and other raw material. Equipment working principle: Longitudinal folding→cutting length automatically→Transverse folding→output automatically→Product stacking, the whole line complete automatically. Width of raw material under 2000mm Folded width longitudinally arbitrary adjustable, the product Cutting length can be adjusted between 350-3000mm, length error of ± 1 mm. Transverse folding: one half ,one- third, one -quarter, one -sixth, one-eighth The machine adopts the cylinder to promote the material and tension control automatically, without manual operation All the drives use the imported servo motor, high precision Touch screen control, only need to enter the data can change the specs, easy to operate. Electronic-control is touch screen man-machine interface operation,built-in production time,counting,a preset number of automatic shutdown, etc. Entire delivery system, strong, durable, non-polluting; Electrical wiring specifications and reasonable, elegant, easy to operate.

Technical parameters:

2.1 Supply Voltage: 380V 50HZ

2.2 Power: 8.5KW

2.3.Weight: 4000kg

2.4.Speed: 0-60 m / min

2.5.Dimensions: 10300 * 2400 * 2150mm

2.6.machine color: silvery white

Equipment configuration list:

3.1 Servo drive: Delta (Taiwan) 5sets

3.2 Gear motors: Yongkun (Taiwan) 1set

3.3 PLC: Delta (Taiwan) 1set

3.4 Motion Controller: Delta (Taiwan) 1 set

3.5 Touch screen: Delta (Taiwan) 1set

3.6 Sensor: Omron (Japan) 3sets

3.7 Inverter: Delta (Taiwan) 1set

3.8 Low-voltage electrical: delixi

3.9 Air shaft: 1set

3.10 Cylinder: airtac 1set

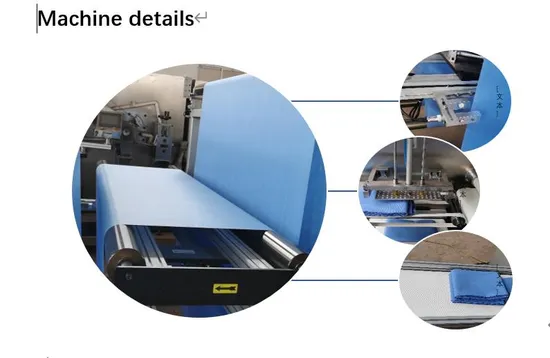

Machine structure Description

The host by the channel steel welded together, solid and firm, surface painting, The feeding part is aluminum alloy rack, the appearance is beautiful and will not get rusted permanently.

Electronic control system

5.1 PLC control system, touch screen man-machine interface operation, easy to operate, humanized design

5.2 Through the man-machine interface to adjust speed, the size of the finished product ,and Stacking quantity.

5.3With Chinese and English operator interface, easy to operate

Installation and terms of Service

6.1 we provide door to door service for domestic customers, foreign customers need to install the machine by themselves. Our engineer at the request of foreign customers can door-to-door service, but users are responsible for accommodation, round tickets visa fees and so on (domestic except). And pay our engineer 100USD one day

6.2 The seller is responsible for equipment packaging costs, use FOB export situation

6.3 Random with common wearing parts and special tools

6.4 After leaving Shanghai port the buyer is responsible for the freight, insurance premiums and unloading

Warranty scope and manner

7.1.1 Since user as the date of buy is responsible for one year warranty.

7.1.2 warranty item: machine transmission and electronic control system

Warranty manner

7.2.1 If some parts damaged, users can disassemble send manufacturer or repair the exchange.

7.2.2Our engineer at the request of customer can door-to-door service, but users are responsible for accommodation, round tickets visa fees and so on (domestic except).

In the following circumstances, our factory is not responsible for warranty, execute collect fees repair:

7.3.1. Artificial damage, such as the machine damage cause by foreign body in fall.

7.3.2. Users without manufacturers agreed to repair itself or has been disassembled.

7.3.3. Users without changing accessories etc.

7.3.4. Customer production voltage instability caused electric damage.

7.3.5. The user handling of corruption.

Considerations

8.1 The machine main components should be checked regularly, Such as welding and cutting bearing working case, filling oil appropriately to ensure that it is working properly.

8.2 Periodically check the wear of the welding, Appropriate adjust the pressure, In the case of guarantee welding well, make the pressure minimum.

8.3 Each unwinding trays tension should be checked in order to adapt to the production needs.

8.4the cutter pressure should be appropriated, otherwise easily lead to a situation such as knife fight

free parts

9.1 wrench : 1 piece

9.2 cutter : 2 pieces

Quotes and payment

10.1payment: After 30% of the total value is paid in advance by (T/T),

The left 70% should be paid by (T/T) after you check up the finished

machine. And the cargo will be delivered after all the payment

arrives at our account.

10.2 The quote is valid: 30 days

10.3 Delivery Date: Within 30 working days after receipt of prepayment from customers

Folded width:under 30cm

material width :under2000mm

>> Metal Adjustable Advertising Exibition Stand for Poster Display

>> Modern Stone Bathtub Design Nero Marquina Black Marble Bathtub for Home Decoration

>> 120/80m³ /H Truck-Mounted Concrete Boom Pump 37m Diesel Concrete Pump Truck Hb37V

>> Marine Hardware Heavy Duty Black Ship Mooring Hall Anchor

>> Ukiss Car bumpers For 2014-2017 Land Rover Range Rover Exclusive Upgrade SVO Body kits Car Grille Diffuser Tips Side Skirt

>> High Efficiency Plastic Crusher PP/PVC Second Hand Plastic Grinding Machine for Industry

>> Plastic Hanger with 15 Clips for Multifunctional Use Drying Rack Hanger Clothespin

>> Small Aluminium Post Work Lift Hydraulic Platform

>> Hotel Terry Open Toe EVA OEM Logo Slipper (GH003)

>> Resilient HDPE Pipe for Agriculture Use with High Impact and Easy Setup

>> Ferro Alloy Steelmaking Mc Fecr68c0.05 Micro Carbon Ferrochrome

>> Environmentally-Friendly Biodegradable Antimicrobiai Case for iPhone 11 Phone Case for iPhone 12 PRO Max

>> 1500d High Tenacity Low Shrinkage Polyester Yarn Filament for Coating Fabric Tarpaulin (China factory)

>> Glass Tube CO2 Laser Engraving Cutting Machine for Nonmetal Materials 9060/1280/1390/1325

>> 2022 hot sale hand corn sheller/home use corn sheller/mini corn thresher machine

>> High Quality classic mens watches black stainless steel watch Japan Movement Magnifying glass Business Couple Wristwatches

>> Tank Lp for LPG Storage Gas 10 Tons

>> High Pressure Stainless Steel 304 316 Vacuum Seal Metal Bellows Edge Welded Vacuum Bellows

>> 94% Food Grade Sodium Tripolyphosphate STPP Detergent Powder for Food Additives

>> Modern Simple Nordic Living Room Furniture Hotel Home Restaurant Natural Wood Rotatable Dining Table

>> 26 Inch Powerful Wind High Air Velocity Ventilator Factory Manufacturer Electric DC Motor Heavy Duty Industrial Wall Mounted Industrial Fan

>> HC-L055 factory low price dentist equipment dental chair LED light source Controlled integral dental unit

>> Automatic Weighing Potato Chips Grain Flour Nuts Chocolate Milk Rotary Doypack Raisin Packaging Machine

>> Eco-friendly Bamboo and Biodegradable Drinking Straws 100% Natural Customized Package Acceptable

>> G720 Xbr-G350wpsac-R Xbr-G350wpsac-F 350W AC Power Supply with Nonport-Side Exhaust Airflow

>> Horizontal Retroreflectometer Road Marking Reflecting Measuring Instrument Retroreflectometer

>> New Zealand Baby Powder Dry Powder Horizontal Mixer

>> RC Car Electronic Speed Controller ESC for RC Car & Trucks, 3-6s, 160A

>> Rena Pet Hot Selling Monster Shape Animal Squeaker Stuffed TPR Pet Dog Feeding Plush Toy

>> Hydraulic Travelling Head Automatic Die Cutting Press Machine