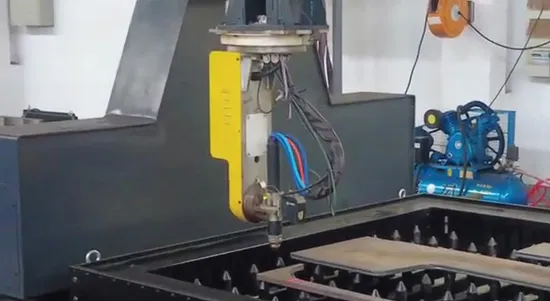

Intelligent Vision Scanning Parts Bevel Plasma Automatic Cutting Machine

| US$10,000.00-30,000.00 | 1 Piece (MOQ) |

Basic Info.

Application

Metal

Process Usage

Metal-Cutting CNC Machine Tools

Movement Method

Contour Control

Control Method

Semi-Closed Loop Control

Numerical Control

NC

Processing Precision

0.09~0.1(mm)

Performance Classification

Mid-Range CNC Machine Tools

Certification

ISO 9001

Condition

New

Transport Package

Box

Specification

ISO9001

Trademark

CRRC

Origin

China

HS Code

8456901000

Production Capacity

100/Year

Product Description

3D CNC cutting machine

Product Description

Special parameters:

| Plate thickness | 5mm-100mm |

| Groove type | V type, Y type, X type, K type |

| Cutting accuracy | blunt edge accuracy: ± 1.0mm, bevel Angle accuracy: ±2.0° |

Technical Parameter:

| cutout type | Center hole, eccentric vertical hole, eccentric normal hole |

| bevel type | Straight mouth, V type, Y type, X type, K type, the maximum bevel angle is 45° |

| cutting accuracy | Hole size accuracy: ±1.0 mm; Bevel angle accuracy: ±2.0° |

| head type | Ball head (HHA), oval head (EHA, EHB), dish head (THA, THB) |

| head size | 300-6000mm (can be customized according to customer needs) |

CRRC QISHUYAN is active in the cutting business already more than 10 years.Produce your parts with already drilled holes, countersinks, threads, or milled openings and weld preps: supplementary machining technologies turn cutting machines into multifunctional production centers!

We are delighted that many of our ideas and visions find appreciation by the industry to establish automated bevel cutting as the process

parts, not only in plasma but also for laser and the last 5 years over 50% of machines were supplied with bevel cutting technologies.

The basic step in production of pressure vessels is precise cutting of dished ends. Automating this process to a high degree while delivering high-precision contours without the need of additional surface finishing provides manufacturers with a clear advantage and saves them a lot of valuable time.

Our philosophy is to deliver machines that are not isolated tools but form an organic part of the production workflow by exchanging information, predicting break-downs and automatic the material flow throughout the customers production cycle. For this we are taking our digital environment to the next level: the new generation of control system highlights digitalization and comes with tools and applications that enable a seamless integration of our machinery into Smart Factory solutions.

Detailed Photos

Our Advantages

We have world-class manufacturing equipment, processes like casting, forging,welding, heat treatment, machining, gearing, can all be done in house.

CRRC QSYRI engages in the research of casting processes and material technologies, along with the development and manufacture of various castings, including cast steel, cast iron, nonferrous metals, high-temperature alloys, stainless steel and cobalt-base alloys, of which high-phosphorous brake shoe, Grade B steel, Grade B+ steel, Grade C steel and Grade E steel, and their manufacturing technologies have been popularized successfully in railway industry.Low-pressure casting Centrifugal casting Metal mold casting Green sand casting Resin sand casting Pre-coated sand casting Sodium silicate sand casting Precision investment casting Bimetal liner preparation MAGMA software for solidification simulation Cast steel, cast iron, aluminum alloy and magnesium alloy development.

The company is also engaged in the R&D of precision forging, heat treatment and product. Its forgings for large-capacity dampers, ND5 major-minor connecting rods, axle of 2000mm, brake disc and gear have been used widely in railway industry. Its forgings of high temperature alloy turbine blade has been used for gas turbine in war ships. Its valve body forgings have been used for petroleum industry. The company owns an internationally advanced electric screw press with a maximum pressure of 22,000 t.

Forging CAD/CAE

Controlled atmosphere heat treatment Precision forging of nonferrous,ferrous metals, stainless steel, high temperature alloy, titanium alloy

The company involves in the R& D of various heat treatment processes and quenching mediums, including cemented quenching, carbon-nitriding, induction quenching and tufftriding. The company operates internationally advanced pit-type and box-type carburizing furnace production lines, as well as quenching press and induction quenching machine production lines introduced from Germany, and keeps ahead in the country in terms of gear heat treatment technology.Controlled atmosphere carburizationSalt bath tuffnitriding Fast and deep ion nitriding Medium & high-frequency quenching and equipment design Heat treatment deformation control.

The company is devoted to the R&D of welding processes and equipment for stainless steel, aluminum alloy and alloy steel. The company is equipped with advanced welding and cutting equipment including longitudinal sheet welding machines, NC air plasma cutters, Miller aluminum alloy welding machines, LVD NC sheet shearing and bending machines, large-sized vacuum brazing furnace, and has developed and manufactured aluminum air reservoirs, water tank, battery box, water-cooled radiators.

The company is also dedicated to the R & D of surface repairing and hardening technologies for large-sized components with flame-spraying, plasma spraying and electrobrush-plating techniques. Its Miller plasma spraying system can produce transferred coatings of metals, alloys and ceramics.

Flame spraying, arc spraying, plasma spraying, and the equipment Electroplating, chemical plating and electro brush platingChemical surface treatment includinganodizing, chemical oxidizing, passivating,phosphating and coloring

Company Profile

CRRC Qishuyan Institute Co.,Ltd is a state-own company affiliated with CRRC group. Found in 1959, it locates in Changzhou city in the great Shanghai region.Focus on R&D of critical equipment for China railway industry, it is a specialized research institution for new material and processes for locomotive and rolling stocks, as well as a high-tech manufacturer of critical parts and components for railway transportation.Currently, it has about 3,000 employees working in 6 production sites, its revenue exceeded 700 million USD in 2020.

Rail transit equipment, automobiles and new energy vehicles, ships and marine engineering equipment, aerospace vehicles, energy-saving and environmental protection equipment, wind power generation equipment, mining machinery, robot parts, construction machinery, mechanical and electrical equipment, transmission devices, instrumentation, electronic appliances, plastics R&D, design, manufacture, sales, repair, leasing, and technical services of products, metal products and parts; Mold manufacturing, sales, repair, and technical services; Metal casting, forging, and welding; Surface treatment and heat treatment; Orbital welding Engineering construction; Product testing and testing; Professional technical and operational skills training (excluding vocational certificate training recognized by the state), technical and management consulting, conference services; Rental of self-owned houses and equipment; Self-operated and agency of various commodities and technology import and export business (except for goods and technologies that are restricted by the state or prohibited from import and export); Design and produce print advertisements, and use the company's public publications to publish domestic advertisements.

Cooperation case display

Certifications

FAQ

1. How long is the product warranty period?

A: Two years.

2, how to place an order to our company?

A: After the products you need are confirmed by both parties, our company will sign a contract with you, and we will execute the delivery and other related matters according to the contract terms.

3. How to distribute the product?

A: We generally provide FOB prices, and the freight is borne by the buyer. If the buyer has the demand, we can also provide CIF price, our company is responsible for shipping products.

4. Settlement currency?

A: We can settle in RMB, USD and Euro.

5. Return policy?

A: In case of any problem with the product, the two parties shall negotiate a return or exchange according to the terms and conditions of the contract.

6. After-sales problems?

A: If there is a quality problem during the warranty period, our company will answer it to the customer within 24 hours. If the problem is more serious, our company will arrive at the customer site within a week to answer it. Products beyond the warranty period we provide maintenance services, provide paid replacement parts, provide paid customer on-site service.

7, how to buy the fragile and consumable parts in the product?

A: Our company will make a list of vulnerable and consumable parts and provide channels for purchase.

>> Newest Design Home Gym Adjustable Custom Dumbbell Set with 1-13.5 Kg

>> Stainless Steel Round Chain of 316/304 Material for Chain Block

>> China Supplier Manufacturer 65mm Bamboo Toothpicks In Bulk Disposable

>> Automatic powerful axial fan flap slide valve type turnover plate type counterflow cooler soybean meal pellet cooling machine with vibration screen

>> Different Giraffe Wood Animal Pop-up Push Puppets Wooden Push Finger Toys

>> HC-R004 Medical digital radiography Veterinary 50MA Medical x-ray machine/animal x-ray machine for vet

>> AS2047 fenster aluminium tilt&turn window with hollow glazed

>> CYLINDER HEAD GASKET FIT FOR FIAT UNO/PALIO/SIENA FIRE 1.3

>> High Pressure China Hydraulic Double Gear Pump Cbgnl for Sale

>> Domestic Water Filter Reverse Osmosis System with Iron Plate Water Purifier

>> Oil Filters Multi Core Filter Vacuum Filtration Filter Stainless Steel

>> Four Wheeler All Terrian Quad Bike 1200W48V20ah Shaft Drive Electric Mini Quads ATV for Kids

>> Nc Thin Blade Slitter Scorer Machine for Optimal Precision and Performance

>> ABB PP877K Module

>> Guichun High Speed Weaving Machine Crank/Cam/Dobby Series 190cm-280cm Waterjet Loom

>> Full automatic wheat straw biomass briquette making forage hay grass solid waste coal block forming feed processing cube size alfalfa pellet press machine

>> Top Punches High Availability Waste Motor Small Double Shaft Fabric Shredder Waste Wood Shredder Mini Shredder

>> Sit on Top Fishing Canoe Kayak for Sale

>> UPVC Profile Screen Sash For Plastic Sliding Windows Glassgrill design modern sliding windows

>> biochar coconut shell charcoal briquettes machine price

>> Large Volumehorizontal Disc Type Sand Ball Mill Grinding Mill

>> Um Wheeled Hand Push Power Tiller Weeder Cultivator Machine

>> Custom Logo Water-Resistant Single Tote Bowling Bag Pink Bowling Bag for Women

>> Wholesale Custom Outdoor Steel Metal Parcel Post Letter Mail Drop Delivery Box

>> Solar Road Stud, Solar Warning Light

>> Automatic Rotating Buckle Shoe Lace Shoelace for Kids Sport Shoe

>> China Supplier High Quality Building Decoration Decorative Finish Aluminum Composite Panel

>> Factory direct for home commercial blender blender juice extractor

>> Hzs120 Concrete Batching Mixing Plant From China

>> Top Selling Bomber Jacket Top Quality Original jeans Jacket hooded Bomber jacket