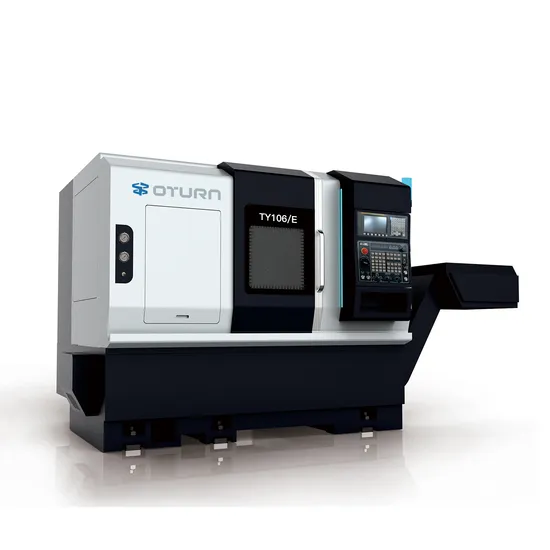

Automated CNC Slant Bed Lathe Ety106 for Heavy-Duty Precision Machining

| US$28,500.00-182,000.00 | 1 Set (MOQ) |

Basic Info.

Model NO.

ETY106

Type

Turret Lathe

Processing Accessory

Chuck CNC Lathe

Guide Rail

Inclined Guide Rail

Tool Holder

Single-tool Holder CNC Lathe

Power Source

Electric

Controlling Mode

CNC

Automatic Grade

Automatic

Setting Mode

Floor-type

Precision

High Precision

Certification

GS, CE, ISO 9001

Condition

New

Control System

Fanuc, Siemens, Mitsubishi

Spindle

A2-6,A2-8,A2-11

Chuck

6,8,10,12inch

Tool Turret

Vdi or Bmt

Motor Power

11,15,18.5,22kw

Transport Package

Plywood Case

Specification

2200x2000x1800

Trademark

Oturn

Origin

China

HS Code

8458110090

Production Capacity

1000/Year

Packaging & Delivery

Package Size

220.00cm * 200.00cm * 180.00cm

Package Gross Weight

3600.000kg

Product Description

Product Description

The machine adopts an optimized 30-degree inclined structure design, which also has high precision, super rigidity and excellent cutting.

stability. High-strength HT300 cast iron one-piece solid structure lathe, using finite element analysis, the overall machine

It has excellent rigidity and stability, and can maintain long-term reliable accuracy, improve processing stability and tool life, and eliminate stress.

In addition to improving precision and stability, the high-strength roller linear rail design structure and the transmission system adopts screw pre-tension design to improve

Reflecting rigid performance, the simple and elegant appearance is in line with the trend.

Main features of this machine tool:

1. Adopting a 30° inclined layout and an integrated structure of the bed base, which greatly improves the bending and torsional rigidity of the machine tool during operation. The high rigidity and high stability of the integrated bed base provide high precision for the entire machine. A strong guarantee.

2. Adopt direct drive synchronous spindle device: magnetic ring incremental encoder (sine and cosine) positioning accuracy: 20 arc seconds, C-axis indexing accuracy: 40 arc seconds. Effectively eliminate spindle vibration, and the nose deflection accuracy is within 0.002MM. Improve the surface finish of the workpiece, adopt a rear-mounted rotor, which makes installation and maintenance faster, the spindle motor is equipped with a cooling system to suppress the influence of thermal displacement and ensure a constant operating temperature of the spindle. The spindle system has undergone strict dynamic balance testing. The good accuracy retention, high rigidity and high efficiency enable the whole machine to not only complete finishing, but also perform rough machining and heavy cutting for users. It is especially suitable for mass production of complex shapes and high smoothness. product.

3. High rigidity overall design servo turret. Equipped with a high-precision clutch to ensure its positioning accuracy and repeatable positioning accuracy. It is equipped with a servo motor to drive the cutterhead to rotate for bi-directional or arbitrary tool selection. The hydraulic principle is used to loosen and clamp the clutch, and the proximity switch feedbacks the clutch action signal to quickly and accurately achieve the tool change action.

4. The machine tool is equipped with roller linear guides and ball screws. The heat-treated and precision-ground ball screws can ensure the best accuracy and durability. Each axis adopts a direct transfer axis structure and a double-anchor pre-relay method to ensure thermal stability. The amount of displacement is minimized, greatly improving processing accuracy. The high-rigidity, large-sized, heavy-duty linear slide rails maintain intact accuracy when the machine is subjected to impact, and the displacement is smooth and low-noise, which can extend the service life.

5. Programmable hydraulic tailstock and high rigidity integral tailstock can eliminate vibration and have good stability. Programmable or manual button control, convenient, fast and reliable.

6. This machine provides users with a complete hydraulic and lubrication system, using high-quality hydraulic pumps, hydraulic valves and other components to greatly reduce the failure rate. The hydraulic and lubrication systems are designed to be simple and reliable. The machine tool adopts centralized quantitative automatic lubrication.

7. It adopts Taiwan rotary chuck cylinder and optional automatic chip removal device, which can greatly reduce the labor intensity of the operator and achieve safe and efficient production. The above functional components can be programmed and controlled, and various functions can be designed and installed according to the special requirements of the user. A special fixture. Product Parameters

| Name | Unit | 106/E |

| Maximum turning diameter on the bed | mm | Φ600 |

| Maximum processing diameter | mm | 360 |

| Maximum processing diameter on the tool holder | mm | Φ200 |

| Maximum processing length | mm | 360 |

| Distance between centers | mm | 450 |

| Spindle nose | type | A2-5 |

| Maximum speed of spindle | rpm | 5500 |

| Oil cylinde/Chuck | lnch | 6″ |

| Spindle bore diameter | mm | Φ56 |

| Bar diameter | mm | Φ45 |

| Direct drive spindle motor power | kw | 11 |

| Spindle motor torque | Nm | 61-125 |

| X axis maximum travel | mm | 200 |

| X/Z axis linear guidel specification | spes | 35/35 roller |

| Z axis maximum travel | mm | 380 |

| X/Z axis motor power | kw | 2.4 |

| X/Z axis fast move | m/min | 30 |

| X/Z positioning accuracy | mm | ±0.005 |

| X/Z repeat positioning accuracy | mm | ±0.003 |

| Servo turret type | pcs | 12T |

| Square tool holder specification | mm | 25X25 |

| Round boring tool holder specification | mm | Φ40 |

| Adjacent tool change time | sec | 0.15 |

| Servo power turret positioning accuracy | / | ±2" |

| Servo power turret repeat positioning accuracy | / | ±1" |

| Programmable hydraulic tailstock | / | Programmable |

| Maximum travel of tailstock | mm | 360 |

| Tailstock sleeve taper hole | type | Morse 4# |

| Tailstock sleeve diameter | mm | 80 |

| Sleeve travel | mm | 100 |

| Machine size(Length*Width*Height) | mm | 2200x2000x1800 |

| Machine weight | kg | 3600 |

| Cutting fluid tank volume | L | 150 |

| Hydraulic unit box volume | L | 40 |

| Hydraulic pump motor power | kw | 1.5 |

| Lubricant tank volume | L | 2 |

| Auto lube pump motor power | W | 50 |

| Cooling water pump power | W | 750 |

Products Configurations

Company Profile

Quality Control

Our Advantages

FAQ

Q1:How can l choose the most suitable machines ?

Please tell me your specications,we can choose the best model for you,or you can choose the exact model,you can also send us the products drawing,we will choose the most suitable machines for you .

Q2: What's your main products of your company?

We specialized in all kinds of machines,such as CNC Lathe Machine ,CNC Milling Machine,CNC Turning Maching,Vertical Machining Center ,Horizontal Machining Center,Lathe Machines,Turning and milling composite processing so on.

Q3: Where is our factory located? How can l visit there?

We have 5 factories located in Guangzhou, Quzhou, Ningbo, and Guangdong.You are warmly welcomed to visit us.

Q4. How do you transport it?

Provide Transportation Solution DDP/CIF/FOB/FCA

Q5: What's the Payment Terms ?

T/T ,30% initial payment when order,70% balance payment before shipment .

06: What's the MoQ?

A: 1 set .(Only some low cost machines will be more than 1 set )

We want to know:

1.We strongly suggest you to tell us size, material of your workpiece for our evaluation if possible, better to send us workpiece drawing, so that we can recommend you most suitable model!

2.lf need ClF Price, please kindly tell us the port of destination.

>> Woodworking Machinery Wood Planer Four Side Moulde

>> Pneumatic stainless steel butterfly valve

>> CNC Vertical Internal and External Compound Grinding Machine Tool Mklf28 Series

>> 3m Lds Diamond Grade Reflective Linear Delineator System of Guardrail

>> Best Selling Micro Sprinkler Head for Garden Irrigation

>> Student Octagonal Pencil Case Made of Oxford Cloth with Multiple Colors Available

>> for TOYOTA car engine coolant thermostat auto parts 9091603099 16340-54020 90916-03099 90916-03062 90916-03072

>> 220--400gms Duplex Paper Gray/White Board

>> Medical Packaging Mold Parts Hot Die Steel Core Pins for Medical Injection Mold

>> Hot Sale M24 Automatic CNC Tapping Machine Universal Servo Tapping Machine Flexible Arm with Touch Screen for Thread Processing

>> SS304 SS316 Stainless Steel Seamless Tube for Mechanical Equipment

>> Engine Hood for 1994-2001 Dodge Ram bonnet

>> Electric Moped Fashionable EEC Motorcycle Scooter Vespa Vehicle Low Price Wholesale CKD or SKD Cheap Adult E Motorcycle

>> Weeding Gasoline Agricultural Rotary Tiller Seeder Seeding Hand Machine for Compact Tractor

>> Premium Water Texture Powder Coatings for Stunning Finishes

>> 50t Kraft Paper Making Machine Cardboard Paper Making Machine

>> Automatic HDPE PE Plastic Bottle Toy Making Maker Blower Blowing Injection Blow Molding Moulding Machine

>> Huayu Plastic Pallet Extrusion Blow Molding Machine

>> Roller type charcoal briquette machine press charcoal powder to charcoal briquettes

>> diamond shaped opening perforated metal sheet metal perforated tray

>> Heavy Equipment UHMWPE HDPE Mud Mats/Waterproof Ground Cover Ground Protection Mats

>> Carbon Steel Flanged Single Parallel Sliding Gate Valves From China Manufacturer

>> Synchronous Servo Driven Diaper Machine for Baby Pant Design

>> High Quality Men′s Polyester Tie Jacquard Designer Stripped Necktie Custom Polyester Promotion Neck Tie

>> High Efficiency Drilling Mud Decanter Centrifuge Sludge Separation Equipment in Chemical Industry

>> Flying Knife Cold Cutting Bottom Seal Plastic Bag Makling Machine

>> Tdc Inserts Holder Ttir20 CNC Turning Grooving Tool

>> Custom Printing 2024 Hardcover Line Journal Box Sets A5 Diary Notebook Gift Set

>> TM-8812 Ultrasonic Metal Thickness Gauge Pipe Wall Thickness Gauge Portable Digital Thickness Gauge

>> 90W High Temperature High Speed Long Axis Oven Motor