10/12/15/18 Holes Paper Egg Tray Pulp Molding Production Line Machine

| US$5,500.00-78,000.00 | 1 Set (MOQ) |

Basic Info.

Model NO.

Wy-1

Application

Agriculture, Chicken Farms

Drying Function

With Drying Function

Automatic Grade

Automatic

Computer Control Panel

Computer Control Panel

Size

Medium

Certification

CE

Condition

New

End-Product

Egg Tray/ Egg Carton/Shoe Tray/ Apple Tray

Guarantee

2 Years

Raw Material

Waste Paper Waste Books, Newspapers

Electricity Power

20-45kw

Voltage

220/380/440V

After-Sale Service

Engineer Available to Abroad to Help Installation

Labor Force

2-4workers

Forming Molds

2 Molds

Dryer Type

4 Layer Metal

Boiler Fuel

Natural Gas, Coal, Diesel, Wood

Transport Package

in Container

Specification

25m*2m*2m

Trademark

Wanyou

Origin

Jinan, Shandong

HS Code

8441400000

Production Capacity

700PCS/H

Product Description

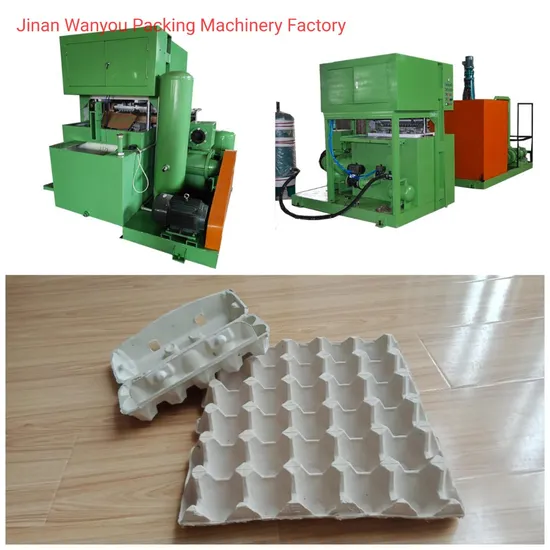

10/12/15/18 Holes Paper Egg Tray Pulp Molding Production Line MachineEgg Tray Machine Introduction: Automatic and semiautomatic egg tray pulp molding machine and production line It is used for making large quantity easy shape products, like paper egg tray, fruit tray, coffee cup carrier tray, bottle tray, wine tray, egg carton with lid, disposable medical products and industrial packaging products etc. Paper Egg Tray Machine Capacity: 350pcs/h, 700pcs/h, 1000pcs/h, 1300pcs/h, 1800pcs/h, 2000pcs/h, 2400pcs/h, 3000pcs/h, 4000pcs/h, 4500pcs/h, 5000pcs/h, 6000pcs/h. Product Type: Egg Tray Machine Process Type: Paper Pulp Molding Production Raw material: waste paper, waste cardboard, newspapers etc. Any type waste paper without plastic. Boiler fuel heating type: diesel, coal, natural gas, or LPG Power Requirement: 20KW-100KW Voltage needed: 220V-440V The semi-automatic egg tray machine production line is not equipped with drying system, after mixing pulp process and automatic forming process, the wet egg trays will be moved to another place for drying by workers, and then product can be dried by sunshine. The semi-automatic egg tray machine production line is suitable for all kinds of paper pulp molded product.

The automatic egg tray machine production line is equipped with one drying system, after mixing pulp process and forming process, the wet egg trays will be transferred to the drying oven automatically by chains, and then product can be dried in the oven with hot air supplied by the boiler. The automatic egg tray machine is suitable for clients who wants big capacity of paper egg tray/egg carton/shoe tray/ bottle tray demand.

Technical Specification of Paper Egg tray machine

| Egg Tray Mold Quantity | 2pcs | |

| Raw material | Waste paper | |

| Egg tray Capacity | 700pcs/hour | |

| Net weight per piece (gram) | 70g-75g | |

| Waste paper consumption | 0.06ton / hour | |

| Water Consumption | 0.1ton/hour | |

| Natural Gas Consumption of Dryer | 25cbm/h | |

| Worker requirement | 3-4workers | |

| Power Requirement | Without dryer | 30KW |

| With dryer | 45KW | |

| Area of workshop | Without dryer | More than 100 M² |

| With dryer | More than 240 M² | |

| Container Requirement | Without dryer | 20ft*1 |

| With dryer | 40ft*2+20ft*1 | |

| Remarks: 1. The Capacity calculated base on 30-packed egg tray(size 300x300mm, weight 70g~75g). 2. Workshop size is for reference only and could be adjusted according to actual size of client's plant. 3.The above specification is for reference only, due to continuous technology development, data will be updated from time to time. 4.Paper Pulp Molding Machine are non-standard equipment, we are able to provide customized solution according to specific requirements from customer. 5.Welcome to contact us anytime, our professional team will provide more effective help and supports for you. | ||

Egg Tray Machine Pulping System Pulping Process

It is the process of mixing the raw materials with water. Then you can get the slurry that is dried to form the egg trays.

Egg Tray Machine Forming system Air Compressor, Vacuum Pump, Motors

Drying system Boiler(Natural Gas Fuel) for Metallic Dryer oven

It basically involves drying the wet semi-finished products by using egg tray drying line.

Good dying process can lead to minimal losses of poorly-formed trays. There are metal and brick egg tray drying line.

Molding Process

Use negative pressure and vacuum absorption to turn slurry to egg trays. If you change the mold, you can make egg cartons, apple trays and so on with egg tray machines.

Egg tray molding area.

Packing process

With hot press machine, we can squeeze large amounts of egg trays into together. Thereafter, egg trays will be packaged in the desired way. Also, it is convenient for conveying egg trays after hot press.

Certificate of egg tray machine

End Products Of Paper Egg Tray Machine

Paper egg trays are the end products of egg tray plant. Egg trays are good protection shell for eggs during transporting and storage. Usually, the egg trays has 30 holes. Esle, there are 10 holes egg trays, 12 holes egg trays, 24 holes egg trays etc. What's more, if you change the mould, the machine can be used to make apple trays, egg cartons and so on.

Raw materials to make egg trays: original wood pulp, craft paper, A4 paper, paper box, old newspaper, old books and other kinds of recycled papers.

Delivery

FAQ:

Our productionline has Fully Automatic and Semi Automatic two types , both have computer control system .

1. What is Semi Automatic type ?

If only order The 1st and 2nd compulsory parts , that's Semi Automatic because you'll have to do the work of drying up egg tray manually;

2. What is Fully Automat type ?

Meaning: the production line includes the Drying system and the whole procedure can be done Automatically .

Of course, the price and the required work space would have big difference from the semi-automatic type.

3. Quality

--- Our machines use UK Technics and part of the components are Germany-made (ex: Ball valve) .

-- Our machine is made by Tooling NOT by Welding , insuring a minimum of 10 years' lifespan .

-- The Egg tray moulds material is Aluminium which can keep the fixed shape much better than that made of rubber material.

--- 99.9% of Success rate: Even if there is a failed egg tray , just throw it back to Pulping area and it can be re-used avoiding waste ;

--- Our machine has been sold to worldwide for over 10 years with continued re-order by some customers with their business grow .

4. What kind of material we can use as the raw material?

Any kind of waste paper like old newspaper,magazines,books,A4 paper etc, and easy to get

5. What kind of Fuel can be used for the whole production line?

Coal, natural gas, and dieseal oil.

6. What kind of products can be made by this machine?

All paper package such as paper egg tray, egg carton,egg box, fruit tray, bottle tray, cup tray, consumer product package, medical disposable container etc.

7. Are you a manufacturer?

Yes, Jinan Wanyou has been fabricating pulp molding machine since 2008. We are one of the most important pulp molding machine manufacturer in the world, and we are famous pulp molding machine manufacturer in China, providing high quality and production capacity pulp molding machinery at reasonable prices to the world.

Our Services

(1)Technical consultation ;

(2)Detailed design of customer workshop ;

(3)Installing and testing the whole production line before shipment;

(4)Training engineers and workers;

(5)Supplying spare part for long time;

(6) Online services anytime.

>> Super Fast Light Absorption Glow in Dark Pigment for DIY Htv

>> Hz-5100s Portable Circuit Breaker Loop Resistance Measurement Instrument 100A Handheld Contact Resistance Tester

>> Guangzhou Cheap BOPP Waterproof Logo Brand 3inch Printed Adhesive Tape with ISO 9001

>> Zys CNC Raceway Grinder for Ball Bearing Inner Ring 3mk205 CNC Grinding Machine

>> Timing Kit Part Timing Guide Rail for MERCEDES-BENZ Engine OEM NO.6010500216 6010500416 6010500816 TR1083

>> Private Label Double Edge Bamboo Razor

>> Wholesale Metal Enamel Pin Badge Custom Sandbag Cat Souvenir Gift Lapel Pin

>> Outdoor Solar Street IP65 LED Waterproof Backyard/Garden/Park 70W/80W/100W/120W Lighting/Lights/Light/Lamp

>> Powder Automatic Batching System for Rubber Mixer Kneader

>> Customized Sublimation Hoodie Design for Men

>> Longhua Trimming Machine PLC Intelligent Control Trimming Efficiency Improvement

>> Chinese Tablet Hardness Tester in Laboratory for Pharmaceutical Industry

>> Wear Block Cemented Tungsten Carbide Inserts with High Hardness Grade

>> Luxury black craftsman large entrance front high security exterior double french wrought iron door

>> New Design Thick Bottom 100ml 3.4oz Glass Perfume Bottle Beauty Cosmetic Bottle

>> Jingwei Brand Jwm-SIM-07 High Quality High Capacity Two for One Twister Machine

>> Heavy Duty Truck Coolant Temperature Sensor Auto Parts Wholesale

>> Taijia Seismic equipment for sale portable rebar testing equipment rebar scanner detector locator

>> Laboratory Scale Digital Laboratory Basket Bead Mill

>> Large Diameter Carbon Steel Tube Hot Rolled Welded Pipe AISI 4140 Alloy Tube 4130 Chromoly Seamless Steel Pipe 42CrMo4 1020 1045 5120 5140

>> New Design Fishing Rod/Carbon Fiber Tube Rolling Machine Production Line

>> Complete Portable Mobile Crushing Plant, Quarry Mobile Granite Limestone Gravel Jaw Crusher

>> Taizhou High Quality Pet Preform /Water Bottle Preform/ Pet Preform Bottle Mould

>> Aluminum Alloy anti-skid strip manufacturers

>> Digital Robot 500c Fully Automatic Fast and Accurate Single-Clamp Perfect Binder

>> FCL Door to Door LCL DDP (Delivered Duty Paid) Shipping to Tanzania by Sea and Air

>> Best Price Pure Podophyllin Powder 50% Podophyllum Resin Podophyllin

>> Plastic/LDPE/PE/PP/HDPE/LLDPE/BOPP/Film/Foil/Woven/Bags/Raffia/Centrifugal/Dewatering/Squeezing/Squeezer/Pelletizing/Pelletizer/Dryer/Machine

>> Manual Dro Milling Machine X6336 Taiwan Turret Milling Machine Price

>> Xieli Machinery China Factory Precision Centerless Grinding Machine with Diamond Grinding Wheel Good Price Range 0.8-70mm