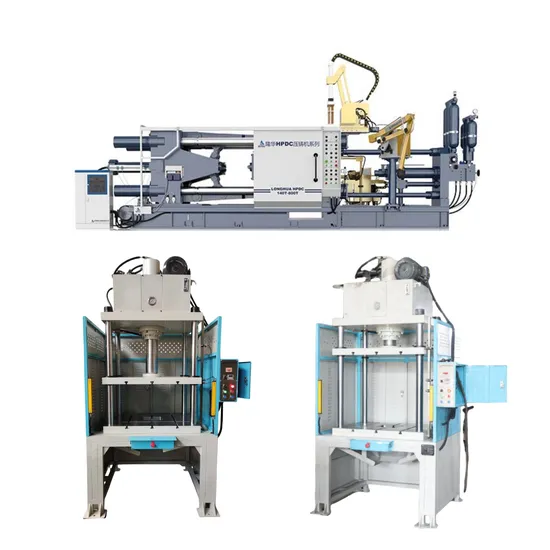

Longhua Trimming Machine PLC Intelligent Control Trimming Efficiency Improvement

Basic Info.

Model NO.

LH-TRIMMING-20T

Driven Type

Electric

Speed

Medium Speed

Transport Package

Simple Packaging

Specification

1500*1300

Trademark

LONGHUA

Origin

China Anhui

Packaging & Delivery

Package Size

700.00cm * 600.00cm * 1200.00cm

Package Gross Weight

300.000kg

Product Description

Introducing our Cold Chamber Die Casting Supporting Equipment Trimming Machine, designed for post-processing in the metalworking industry. The trimming machine is essential for edge trimming of die-cast products, removing burrs and irregular edges to achieve a smoother surface and enhance product quality.Working Principle:

The trimming machine utilizes rotating cutting tools to trim the edges of die-cast products. The cutting tool speed and method can be adjusted according to product requirements. Various types of cutting tools are available to accommodate different shapes and sizes of die-cast products.

Advantages:

Efficiency: Automated operation allows for fast cutting and continuous production of finished products.

Precision: Cutting tools ensure precise control over cutting position and angle, ensuring smooth and consistent product edges.

Reliability: High-quality cutting tools and stable control systems guarantee equipment reliability and stability.

Applicability: The trimming machine is adaptable to various shapes and sizes of die-cast products, demonstrating strong versatility.

Due to the continuous advancement of technology, die-casting machine drawings, parameters, configurations, performance, etc. are subject to change without prior notice. Application:

The trimming machine finds wide applications in metalworking processes in industries such as automotive, electronics, and home appliances. It enables quick and accurate edge processing of die-cast products, enhancing product quality and appearance.

>> Delta 19V 65W ADP-65JH HB laptop adapters original and new CE UKCA

>> Hot-Sale Simulation Artificial Plants Greenery Anthorium Decor Decorative Hanging Pothos Home Decoration

>> 2 Cavity Semi Automatic Bottle Blowing Machine Blow Molding Machine Small Blow Molding Machine

>> Outdoor Double Heavy Teak Spreader Bar Poly Cotton Thick Rope Net Hammock

>> Ss Round Square Cold Hot Rolled ASTM/AISI/DIN/JIS 201 304/304L 316 316L 430 Stainless Steel Seamless/Welded Tube with Pickling Ba 2b Bright Polish

>> Galvanized /Colored Roofing Sheets Cheap Price

>> High Intensity Lifting Salvage Boat Pneumatic Rubber Airbag Ship Rubber Airbag

>> Customized Carbide Cold Heading Die Made in China

>> 40"41"Acoustic Bag Single Bag 600d Material 10mm Thickness Padding

>> Factory Custom Waterproof Children Pupil Primary Student Cute Girls Kids School Bag

>> Heat-resisting stainless steel instant grill disposable barbecue wire mesh

>> Factory hot selling product small vertical granule packing machine fried peanut granule packing machine bright appearance

>> High Standard and Good Quality Jch Roofing Metal Steel Roll Forming Machine

>> Shampower DC 24V 21A 500W Rps Series IP65 Rainproof LED Power Supply for COB LED Strip Lights and UV Soft Film Advertising Light Box

>> Home Hospital Furniture Bedpan Auxiliary Electric Adjustable Bed for Elderly and Disabled

>> New CE Single Phase Hydraulic Electric Log Splitter

>> Auto Engine Accessories Timing Chain Guide OEM NO.504294572 for Citroen

>> DS200TCQCG1BKG GE Unit module controller card

>> Organza Satin Satinado Puntos Oro Sparkle Sheer Grosgrain Satin Double/Single Face Ribbon

>> High Impact Resistance Customizable 9074.17threaded Hexagon Head Structural Screw Assembly

>> UTP CAT6A CAT6 Signal Control Data Coaxial Speaker LAN Computer Network Cable

>> Efficient PLC Controlled Crochet Knitting Device

>> The Mini Marvel Machine: Safe, Compact, and Incredibly Flexible

>> Garment Tag Custom Ribbon Silk Screen Printed Polyester Color Stain Woven Care Label for Fashsion Garment Bags Shoes Hats.

>> Fama Hospital Scrubs Sets Fit Scrubs Pharmacy Nurse Uniform

>> Hot Selling PF Series Stone Impact Crusher Price for Calcium Carbonate Gypsum Limestone Quartz Graphite Calcite Feldspar Fluorite Powder Plant

>> Ultrasonic System For Cosmetic Tubes Wood Cap Ultrasonic Plastic Filling And Sealing Machine

>> Super Mute Thin Rechargeable Bluetooth Mini Wireless Laptop Portable Bt Mouse PC Laptop Notebooks

>> High Precision Pipe Threading Q1322 Horizontal Metal Lathe Machine

>> 2022 Writing Note Pad Custom Print Memo Pads Tear off Magnet Notepad with Pen